In modern experimental research, many chemical reactions, material preparation, and sample processing procedures have extremely strict requirements for the environment, such as being free of water, oxygen, dust, or specific inert gas atmospheres. The glove box, as an experimental device that can effectively isolate external environmental interference, has become an indispensable core tool in fields such as chemistry, materials science, electronics, and biomedicine.glove box provides researchers with a controllable enclosed operation space, ensuring that experiments are carried out precisely under the preset environmental conditions, significantly expanding the boundaries of experimental research.

The basic structure of the glove box

The core function of the glove box is to create and maintain a specific internal environment. Its structural design is centered around this goal, and it mainly consists of the following key components:

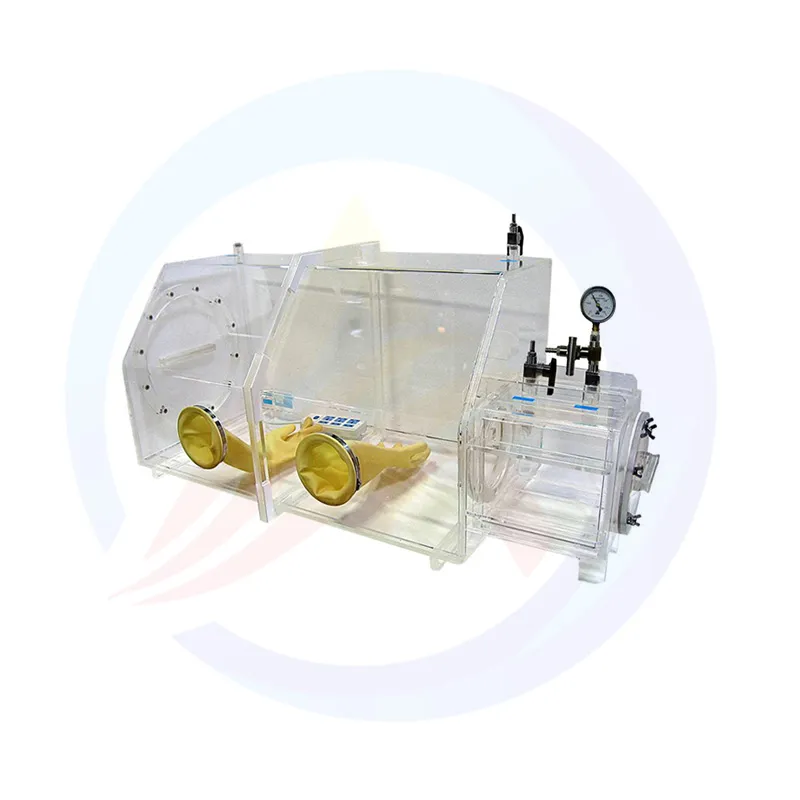

The box is the core working area of the glove box, usually made of stainless steel and featuring high strength, corrosion resistance, and excellent airtightness. The size of the box is determined according to the experimental requirements. Small glove boxes can be used for handling small samples, while large boxes can accommodate complex experimental setups. Transparent observation windows are embedded on the box walls, typically made of polycarbonate or tempered glass, to allow operators to clearly observe the internal operations while withstanding possible pressure changes within the box.

The transfer chamber is the key passage connecting the box and the outside world, used to transfer samples, reagents, or experimental equipment without disrupting the internal environment of the box. The transfer chamber is usually cylindrical or square, with sealed doors at both ends that connect to the inside of the box and the outside. When transferring items, first place the items in the transfer chamber and close the outer door. Then, through vacuuming, filling with inert gases, etc., the internal and external environments of the chamber are balanced, and the inner door is opened to move the items into the box, and vice versa. Some advanced transfer chambers also have heating and cooling functions to accommodate special sample transfer needs.

The operation gloves are the bridge between the operator and the internal environment of the glove box. They are usually made of materials resistant to chemical corrosion and with good flexibility, such as nitrile rubber, chloroprene rubber, or fluorine rubber. The gloves are sealedly connected to the box through special flange interfaces to allow the operator's hands to flexibly enter the box for various operations while avoiding gas leakage from the box and the intrusion of external gases. The size and thickness of the gloves can be selected according to operational requirements. Some gloves also have anti-wear, high-temperature resistance, and low-temperature resistance properties.

The working principle of the glove box

The core working principle of the glove box is to create and maintain a specific gas environment within a sealed space through gas control and purification. At the same time, it enables the safe transfer and operation of samples.

Firstly, the initial environment of the glove box needs to be established by replacing it with inert gases (such as nitrogen, argon). When the equipment is started, the box and the transition chamber are evacuated to a certain vacuum level to remove the internal air (containing oxygen, moisture, etc.), and then inert gas is introduced to the set pressure. This vacuuming - gas filling process may need to be repeated several times to ensure that the air inside the box is fully replaced, reducing the oxygen and moisture concentrations to the required level (usually below 1 ppm).

During the experiment, the gas purification system operates continuously. The gas inside the box flows through the purification column driven by the circulating fan. When the gas passes through the molecular sieve, the moisture is adsorbed; when it passes through the deoxygenizer, the oxygen reacts chemically with the deoxygenizer (such as copper-based deoxygenizers reacting with oxygen to form copper oxide) and is removed; if there are organic volatile substances, activated carbon will adsorb them. The purified gas returns to the box to form a closed loop, maintaining the concentration of impurities such as moisture and oxygen at extremely low levels over a long period.

The working principle of the transition chamber is based on pressure balance and gas replacement. When it is necessary to transfer the sample into the box, the outer door of the transition chamber is opened, the sample is placed inside, and the outer door is closed. Then, the transition chamber is evacuated to remove the internal air, and inert gas is introduced to reach a pressure balance with the box. Finally, the inner door is opened, and the sample is moved into the box. In the opposite case, when removing the sample, the sample is placed in the transition chamber, the inner door is closed, the transition chamber is evacuated, and then air (or other gases as required) is introduced, and the outer door is opened to remove the sample. This process ensures that the inert gas environment inside the box is not disrupted by the outside air during the sample transfer.

Classification of glove boxes

Based on different classification criteria, glove boxes can be divided into various types, each with its own unique design and applicable scenarios.

According to the internal gas environment, glove boxes can be classified as inert gas glove boxes and anaerobic glove boxes. Inert gas glove boxes are mainly used to maintain an inert gas environment and are suitable for experiments that are sensitive to oxygen and moisture, such as the synthesis of metal organic compounds and the preparation of lithium battery materials. Common inert gases used are argon or nitrogen. Anaerobic glove boxes are specifically designed to create an anaerobic environment and usually control the concentration of carbon dioxide to meet the experimental requirements of anaerobic microbial cultivation and biological material degradation. The internal gas in anaerobic glove boxes is mostly a mixture of nitrogen, hydrogen, and carbon dioxide (hydrogen is used to remove residual oxygen).

According to the structural form, glove boxes can be divided into single-chamber glove boxes, double-chamber glove boxes, and multi-chamber glove boxes. Single-chamber glove boxes have a simple structure, consisting of only one main box and one transition box, and are suitable for small-scale experiments or sample handling. Double-chamber glove boxes contain one main box and two transition boxes, which can be used for introducing and removing samples respectively, improving operational efficiency and avoiding cross-contamination, and are suitable for medium-scale experimental operations. Multi-chamber glove boxes are composed of multiple main boxes and transition boxes, and the compartments can be interconnected or independently controlled, suitable for complex multi-step experiments or integrated production lines, such as the continuous preparation process of semiconductor materials.

Applications of glove boxes

Glove boxes, with their ability to precisely control the internal environment, play a crucial role in various scientific research and industrial fields.

In the field of chemical synthesis, many sensitive compounds require a strict aseptic and oxygen-free environment. Glove boxes become the ideal operating platform. For example, organic metal compounds (such as Grignard reagents, organic lithium reagents) are extremely sensitive to water and oxygen. They will rapidly decompose in the air, but in a glove box, researchers can safely perform weighing, dissolution, and reaction operations, thereby increasing reaction yield and product purity. Moreover, in coordination chemistry and catalytic reaction research, glove boxes can avoid the interference of impurity gases on the reaction system, ensuring the accuracy and reproducibility of experimental results.

Proper Use and Maintenance of Glove Boxes

Proper use and maintenance of glove boxes are crucial for ensuring their stable performance and prolonging their lifespan.

Before use, a comprehensive inspection is necessary. First, check the seal of the gloves to see if there are any damages, cracks or looseness. This can be verified by inflating the gloves and observing if there is any leakage. Secondly, check the connection of the gas pipelines and the operation of the valves. Then, confirm whether the purification materials of the gas purification system are effective (such as whether the molecular sieve has lost its activity or the deoxidizer has failed). If necessary, replace them. Finally, check the display of various parameters of the control system to ensure that the oxygen and moisture detectors are calibrated accurately.

During operation, avoid vigorous movements to prevent the gloves from being damaged due to excessive stretching. When transferring samples, strictly follow the operation procedures of the transfer chamber to ensure sufficient vacuuming and inflation, and avoid damaging the internal environment of the box. When conducting heating or generating volatile gases inside the box, open the exhaust valve to appropriately release pressure to prevent excessive pressure inside the box. Operators should wear appropriate protective equipment, such as laboratory coats and goggles, to avoid direct contact with potentially harmful substances inside the box.