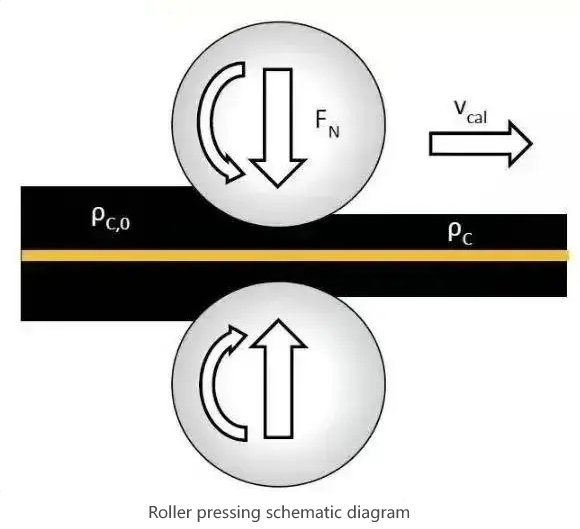

Roller pressing is the process of compacting the coated product through two steel rollers with a certain gap and pressure to a specified thickness.

01. Functions, principles of roller pressing equipment, and factors influencing roller pressing quality

1.1 Functions of the roller pressing equipment

Roller pressing involves compacting coated and partially dried lithium battery electrode sheets. This process enhances battery energy density while ensuring the binder firmly attaches electrode materials to the current collector, preventing material detachment and energy loss during cycling. Prior to rolling, coated electrode sheets must be sufficiently dried to avoid coating peeling from the current collector. During roller pressing, controlling the compaction degree is critical: excessive compaction affects lithium ion intercalation/deintercalation near the current collector, causes active substances to adhere too closely (leading to easy detachment), and may even make the electrode sheet overly plastic, resulting in winding failure or fracture post-rolling.

Rolling is one of the most crucial processes in the manufacturing of lithium battery electrode sheets, and the accuracy of rolling has a significant impact on the performance of lithium batteries.

The purposes of rolling are as follows:

The roller pressing process can keep the surface of the electrode sheet smooth and flat, thereby preventing the risk of battery short circuit caused by burrs on the surface of the electrode sheet piercing the separator and improving the energy density of the battery. The roller pressing process can compact the electrode material coated on the current collector of the electrode sheet, thereby reducing the volume of the electrode sheet, increasing the energy density of the battery, and improving the cycle life and safety performance of lithium batteries.

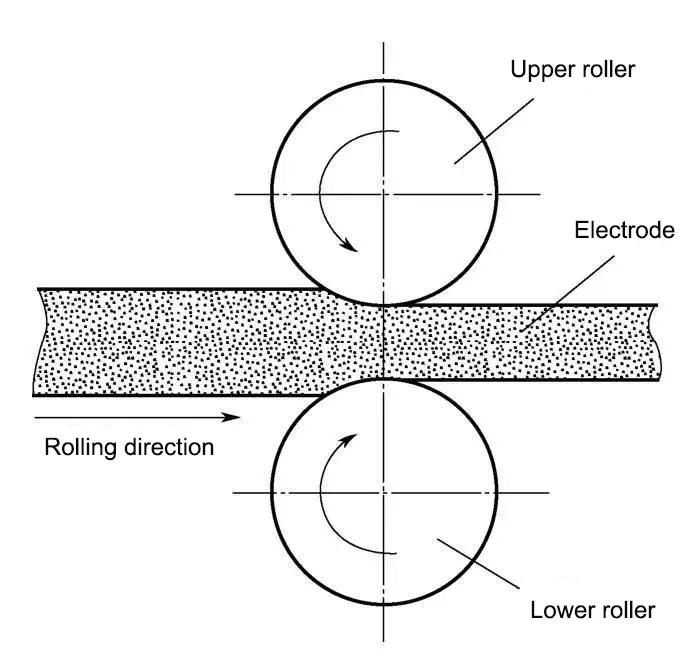

1.2 The principle of battery electrode sheet rolling

The purpose of rolling is to make the active substance and the foil bond more dense and uniform in thickness. The roller pressing process must be carried out after the coating is completed and the electrode sheet is dried; otherwise, phenomena such as powder shedding and film layer detachment are likely to occur during the roller pressing process. The battery electrode sheet is a copper foil (or aluminum foil) coated with electrical slurry particles on both sides. The battery electrode strip undergoes two processes of coating and drying before being rolled. Before rolling, the electrical slurry coating on the copper foil (or aluminum foil) is a semi-flowing and semi-solid granular medium, composed of some unconnected or weakly connected individual particles or clusters, and has certain dispersibility and fluidity.

1.3 Influencing Factors of Roller pressing Quality

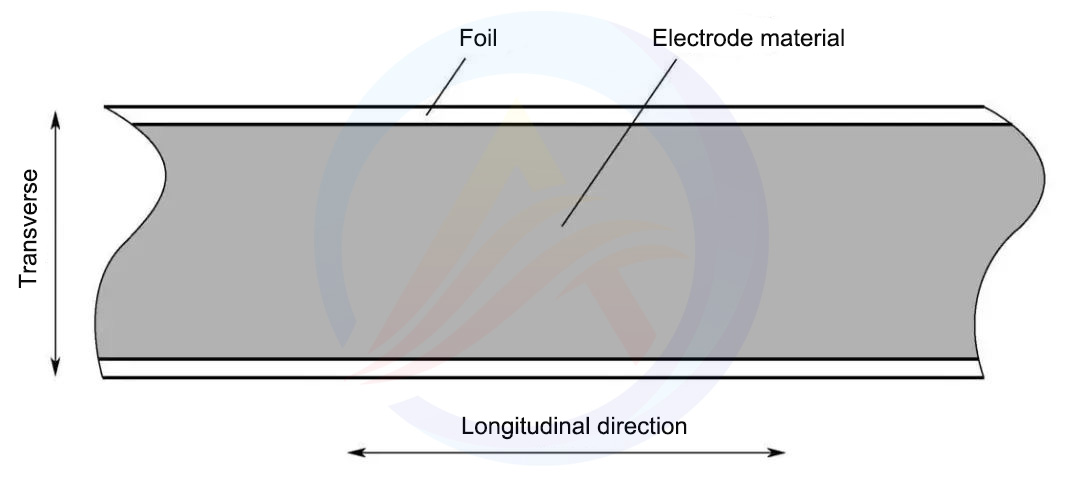

Quality issues in battery electrode sheets due to rolling equipment mainly appear as uneven post-rolling thickness, causing inconsistent compaction density—a critical factor for battery performance consistency. Thickness uniformity includes transverse and longitudinal consistency, with differing causes (Fig. 4). Key factors for transverse thickness non-uniformity include roll bending deformation, frame stiffness, elastic deformation of main load-bearing components, roll pressure, and electrode sheet width.