In the production process of lithium batteries, box furnace and Muffle furnace as commonly used heating equipment, each play a unique role. There are significant differences between them in structure, working principle, performance characteristics and application scenarios.

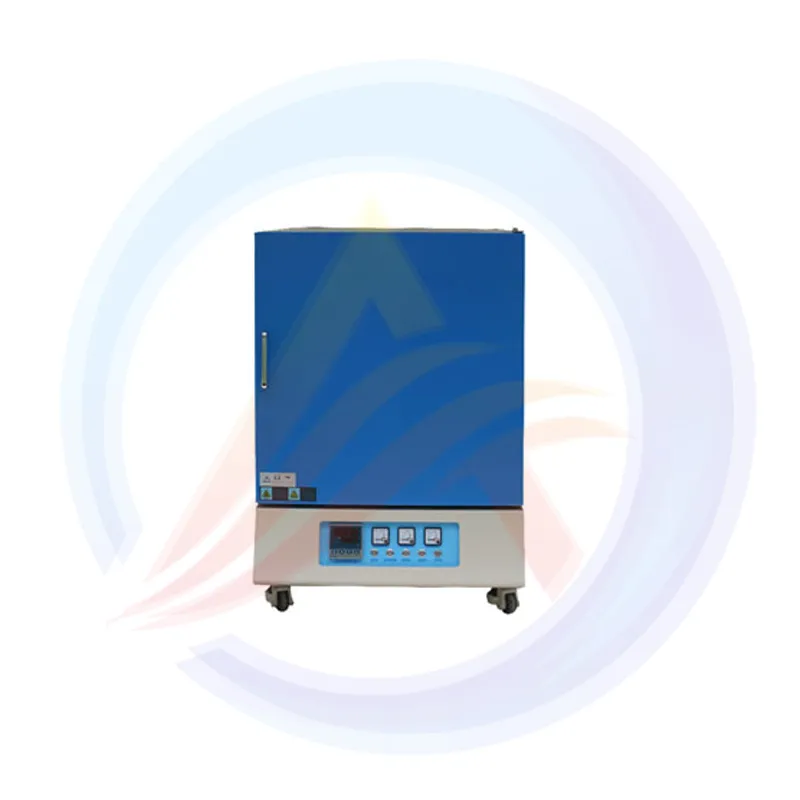

1、the characteristics of the box furnace

(1) Structure and design

Box type furnace is usually composed of box, heating element, insulation layer, furnace door and control system. The box is made of high temperature and corrosion resistant metal material, with good sealing and stability. The heating element is generally installed at the bottom or side of the box, and converts electrical energy into heat energy to provide a uniform heating environment in the furnace. The insulation layer is located inside the box to play the role of heat insulation, reduce heat loss and improve energy efficiency. The design of the furnace door is easy to operate and can be opened and closed manually or automatically to facilitate the entry and exit of materials.

(2) Working principle

The working principle of the box furnace is to use the heat generated by the heating element to heat the air in the furnace through heat transfer, so as to realize the heating of the material. During the heating process, the air in the furnace forms convection, so that the heat is evenly distributed. The box furnace can adjust the temperature in the furnace by controlling the power and heating time of the heating element to achieve the heating demand for different materials.

(3) Temperature control

The temperature control of the box furnace is flexible and can be adjusted precisely according to the requirements of the production process. Generally, thermocouples or temperature sensors are used to monitor the temperature in the furnace, and automatic control of heating elements is realized through the control system. The temperature range of the box furnace is usually from room temperature to about 1000 ° C, which can meet the heating needs of different stages in the production process of lithium batteries.

(4) Application scenarios

Box furnace is widely used in drying, sintering, annealing and other processes of lithium battery electrode materials. In the drying process of lithium battery electrode materials, the box furnace can provide a stable temperature environment, remove water and volatiles in the material, and ensure the quality of the material. In the sintering and annealing process, the box furnace can control the heating temperature and time to make the electrode material reach the ideal crystallization state and improve the performance of the material.

2、the characteristics of Muffle furnace

(1) Structure and design

Muffle furnace is mainly composed of furnace body, furnace chamber, heating element, furnace door, chimney and control system. The furnace body is made of high temperature and wear resistant materials, and the furnace is equipped with a high temperature resistant ceramic lining to protect the furnace body and heating elements. The heating element is generally installed at the bottom or side of the furnace, and provides a high-temperature environment for the furnace by converting electrical energy into heat energy. The unique design of the furnace door is well sealed and can be opened and closed manually or automatically. The chimney is located at the top of the furnace and is used to exhaust the exhaust gas and smoke generated by combustion in the furnace.

(2) Working principle

The working principle of the Muffle furnace is to use the heat generated by the heating element to heat up the material in the furnace through thermal radiation. During the heating process, the air in the furnace forms convection, so that the heat is evenly distributed. The Muffle furnace can adjust the temperature in the furnace by controlling the power of the heating element and the heating time to achieve the heating requirements for different materials.

(3) Temperature control

The temperature control of Muffle furnace is more accurate and can be strictly adjusted according to the production process requirements. Generally, thermocouples or temperature sensors are used to monitor the temperature in the furnace, and automatic control of heating elements is realized through the control system. The temperature range of the Muffle furnace is usually from room temperature to about 1500 ° C, which can meet the needs of high temperature heating in the production process of lithium batteries.

(4) Application scenarios

Muffle furnace is mainly used for sintering, melting and pyrolysis of lithium battery electrode materials at high temperature. In the sintering process of lithium battery electrode materials at high temperature, Muffle furnace can provide a high temperature and high energy environment, so that the electrode material can achieve the ideal crystallization state and improve the performance of the material. In the melting and pyrolysis process, the Muffle furnace can make the electrode material undergo chemical reaction and generate new substances by controlling the heating temperature and time.

3、the difference between box furnace and Muffle furnace

(1) Heating method

The box furnace mainly uses the heat generated by the heating element to heat the material through air convection, while the Muffle furnace mainly uses heat radiation to heat the material. This allows the Muffle furnace to transfer heat to the material more quickly during the heating process, improving heating efficiency.

(2) Temperature uniformity

The temperature uniformity of the box furnace is relatively good, and the air in the furnace forms convection, so that the heat is evenly distributed. Due to the position of the heating element and the effect of heat radiation, the temperature distribution in the Muffle furnace is relatively uneven, and there is a certain temperature difference between the center and the edge of the furnace.

(3) Heating speed

The heating speed of Muffle furnace is fast, and it can reach a high temperature in a short time. The heating speed of the box furnace is relatively slow, and it takes a long time to reach the set temperature.

4、Application cases of box furnace and Muffle furnace in lithium battery production

(1) The application of box furnace in the drying of lithium battery electrode materials

In the drying process of lithium battery electrode materials, the box furnace can provide a stable temperature environment to remove water and volatiles in the material. By controlling the heating temperature and time, the box furnace can make the electrode material reach the ideal dry state and improve the quality and performance of the material.

(2) The application of Muffle furnace in the high-temperature sintering of lithium battery electrode materials

In the high temperature sintering process of lithium battery electrode materials, Muffle furnace can provide a high temperature and high energy environment, so that the electrode materials can reach the ideal crystallization state. By controlling the heating temperature and time, the Muffle furnace can make the electrode material undergo chemical reaction, generate new substances, and improve the performance of the material.

(3) The joint application of box furnace and Muffle furnace in the production of lithium batteries

In the production process of lithium batteries, box furnaces and Muffle furnaces can be combined to give play to their respective advantages. For example, in the drying and sintering process of lithium battery electrode materials, the box furnace can be dried first, and then the material is transferred to the Muffle furnace for high temperature sintering, thereby improving production efficiency and product quality.

5、Conclusion

Box furnace and Muffle furnace have different characteristics and application scenarios in lithium battery production. The box-type furnace is mainly used for the process of low heating temperature and slow heating process, with good temperature uniformity and slow heating speed. The Muffle furnace is mainly used for the process of high heating temperature and fast heating speed, and has the characteristics of fast heating speed and uneven temperature.