AOT-PTL-MM02 program-controlled desktop dip coater through pulling wire, vertical immersion to pull the sample, the sample impregnated in liquid film material for a period of time and then pulled out, so that the sample surface cover a certain thickness of film. The dip coater is controlled by PLC program, which can set the pulling speed, dipping time of sample in liquid film material, feeding speed of sample in liquid film material, cycle times of sample in liquid film material and drying time of sample. It can also be equipped with a constant temperature drying oven, so that the film growth process in a constant temperature. The dip coating machine is compact in size and can save laboratory space, simple operation, suitable for beginners to use, easy to clean up. Therefore, the dip coater is widely used in the laboratories of colleges and universities, research institutes and enterprises.

Product name | AOT-PTL-MM02 Programmable desktop dip coater |

Model | AOT-PTL-MM02 |

Installation conditions | This dip coater requires that below altitude 1000m to use, temperature 25℃± 15℃, and humidity at 55%RH ± 10%RH. 1. Water:unnecessary 2. Electric: AC220V 50Hz, must have a good ground 3. Air:unnecessary 4. Workbet: size 800mm × 600mm × 700mm, load -bearing more than 200kg 5. Ventilation device: no need |

Main parameter | 1. Power supply:220V |

2. Power:50W |

3. Raised speed:1 mm/min-200mm/min |

4. Effective dip length:60㎜ |

5. Dip drying time setting :1-999s |

6. Number of can be lifted: 1-20 times |

7. Lift load: ≤100g |

8. Sample size:75mm×25mm×2.5mm |

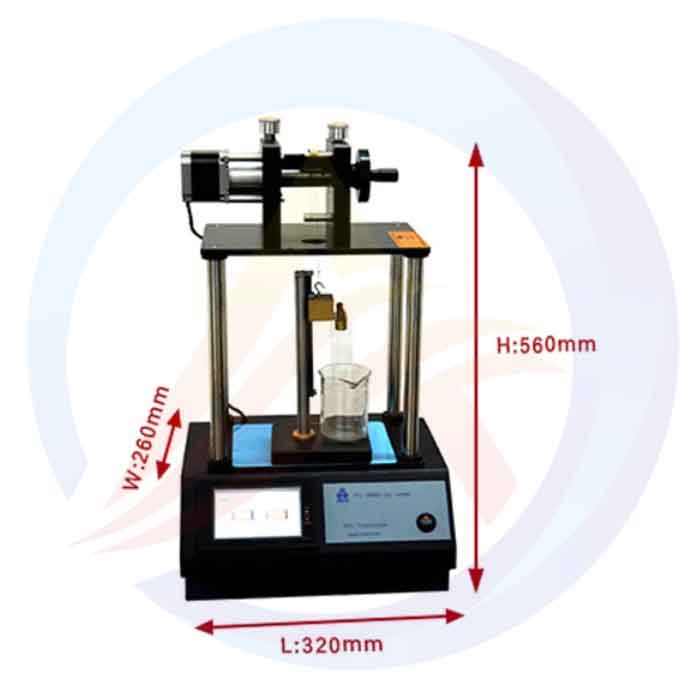

9. Product spec: Size:320mm×260mm×560mm; Weight:17kg |

Company Profile

Xiamen AOT battery equipment Technology Co LTD was set up as a manufacturer in 2006. We have total manufacturing facilities of around 4, 000 square meters and more than 65 staff. Owning a group of experienced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy. AOT Battery has been focused on product development and operations of lithium battery and its surrounding, we supply full kinds of lithium-ion battery equipment, lab battery raw materials and lithium-ion battery research and development technology.

Exhibition

AOT Lithium Battery Equipment exhibition provides exhibitors and visitors with a comprehensive platform for display, exchange, cooperation and trade. By participating in the exhibition, enterprises can understand the industry dynamics, expand market channels, enhance brand image and promote technological innovation and industrial upgrading.

Certificate

Cooperative

FAQ

Q1:What is desktop dip coater?

A:Desktop dip coater is a small coating equipment for laboratories or scientific research. It mainly forms a uniform film on the surface of the substrate by immersing the substrate in the coating solution and then lifting it at a constant speed. It is suitable for the preparation of thin films in fields such as optics, electronics, and materials. It features simple operation, compact size, and controllable coating thickness (adjustable through speed, solution concentration, etc.), and can meet the coating requirements of small-scale samples.

Q2:The role of desktop dip coater

A: Desktop dip coater is mainly used for evenly coating films on the surfaces of substrates such as glass and silicon wafers. Through the dip coating process, parameters such as the lifting/releasing speed and solution concentration can be precisely controlled to adjust the thickness and uniformity of the film. It is suitable for various solution-state materials such as polymers and nanoparticles, and is widely used in the fields of optics, electronics, and materials research, meeting the high-precision film preparation requirements of small-scale samples in laboratories

Q3:The operation mode of desktop dip coater

A: The operation steps of Desktop dip coater are as follows: First, install the fixture, adjust the level and prepare the solution and pour it into the material trough; Then set parameters such as dip coating speed and residence time; Fix the cleaning substrate to the fixture to ensure it is vertical. Start the equipment to immerse the substrate in the solution at a constant speed, hold it for a while, then lift it up to form a film. Finally, the substrate is removed for post-treatment such as drying. Throughout the process, parameters can be monitored through software to ensure uniform coating.