The ultrasonic metal welding machine principle of c is to use the energy generated by the high-frequency mechanical vibration of ultrasonic waves to weld non-ferrous metal materials of the same or different types. During the welding process, neither current is transmitted to the workpiece nor high-temperature energy is input. Instead, it only vibrates repeatedly on the surface of the workpiece at a high frequency of 24.5-25.5KHz And apply the corresponding pressure to the workpiece to form a solid bond between the workpieces, thereby achieving the welding effect.

2. Main features

Precision sliding bearings can ensure the precise movement of equipment and meet the best welding accuracy requirements

The precisely adjustable limit position can accurately determine the up and down position of the welding

The up and down speed of the welding head can be accurately adjusted

The welding time (ultrasonic time) can be accurately adjusted

The time for maintaining downward pressure can be accurately adjusted

The power box can maintain a stable amplitude output when the voltage fluctuates

The unique structural design effectively transmits ultrasonic energy to the welding head

It is made of imported SKD11 material, featuring excellent ultrasonic transmission and long-lasting wear resistance

The overall operation is simple, with high welding efficiency and good welding quality

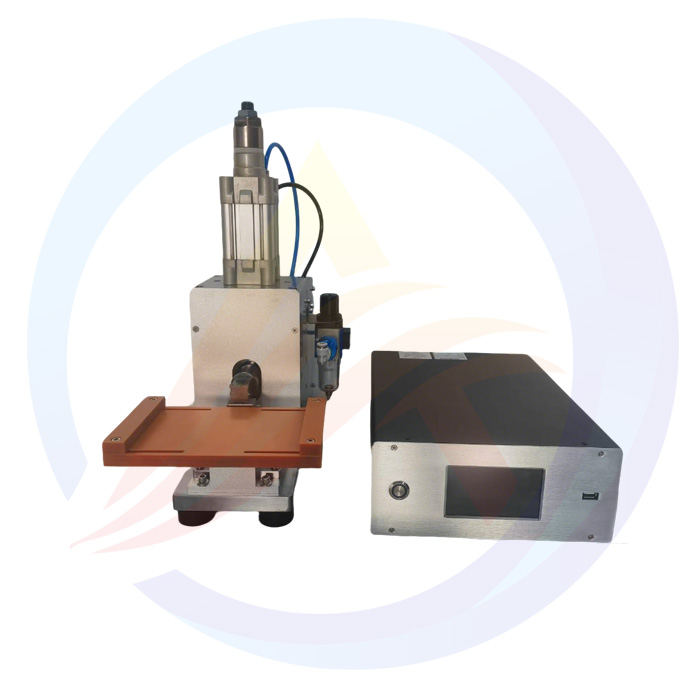

Name | ultrasonic metal welding machine |

Model | AOT - USW - 1000W |

Power | 800W |

Required Power Supply | 220VAC±10%, 50/60HZ |

Frequency | 40KHz |

Required Air Source | Pressure 0.4 - 0.8MPa, Humidity < 45%, Temperature ≤ 50℃ |

Cylinder Bore | 60mm |

Cylinder Stroke | 10mm |

Air Consumption | 0.0785 cubic meters (1L = 0.001 cubic meters) |

Air Inlet Connector | Quick Connector |

Welding Time | Adjustable (0.01s - 10s) |

Pre - pressure Time | Adjustable (0.02s - 1s) |

Frequency Calculation and Display | 24.5000 - 25.5000HZ |

Automatic Frequency Tracking | Range ±20HZ |

Automatic Temperature Tracking | Internal power tube 60° automatic protection |

EMI/EMC | Strong anti - interference ability |

Approximate Overall Size of Welding Head | 480L * 260W * 380H (mm) |

Approximate Overall Size of Main Cabinet | 500L * 360W * 120H (mm) |

Total Weight | 44Kg |

Company Profile

Xiamen AOT battery equipment Technology Co LTD was set up as a manufacturer in 2006. We have total manufacturing facilities of around 4, 000 square meters and more than 65 staff. Owning a group of experienced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy. AOT Battery has been focused on product development and operations of lithium battery and its surrounding, we supply full kinds of lithium-ion battery equipment, lab battery raw materials and lithium-ion battery research and development technology.

Exhibition

AOT Lithium Battery Equipment exhibition provides exhibitors and visitors with a comprehensive platform for display, exchange, cooperation and trade. By participating in the exhibition, enterprises can understand the industry dynamics, expand market channels, enhance brand image and promote technological innovation and industrial upgrading.

Certificate

Cooperative

FAQ

Q.What is a 40KHZ Ultrasonic Metal Welding Machine

A.The 40KHZ ultrasonic metal welding machine is used in the battery field for the production of lithium batteries, nickel-metal-hydride batteries, etc. Through the high-frequency vibration energy of 40KHZ, it can achieve welding of tabs and electrode foils (such as copper and aluminum foil and nickel/aluminum sheets), battery caps and cable shielding layers, etc. Welding does not melt metals, maintaining electrical conductivity. It takes a short time and requires no solder. It is suitable for metals such as copper, aluminum, and nickel, ensuring the structural integrity of the battery and the reliability of electrical connections.

Q.The function of Ultrasonic Metal Welding Machine

The 40KHZ ultrasonic metal welding machine is used in the battery field for the production of lithium batteries, nickel-metal-hydride batteries, etc. It can weld tabs and electrode foils (copper, aluminum foil and nickel/aluminum sheets), battery caps and cable shielding layers. High-frequency vibration is utilized to make the metal contact surfaces frictional and bonded, preventing the material from melting and maintaining electrical conductivity. The welding time is short and there is no solder, ensuring reliable sealing of the battery structure and electrical connection. It is suitable for welding metals such as copper, aluminum, and nickel.