-

Home

-

Products

- Ball Mill

- Lab Furnace

- Battery Mixer Machine

- Battery Coating Machine

- Roller Press

- Electrode Slitting Machine

- Electrode Die Cutting Machine

- Battery Stacking Machine

- Battery Winding Machine

- Battery Sealing Machine

- Battery Spot Welding Machine

- Vacuum Glove Box

- Battery Tester

- Cylindrical Battery Pack Assembly Machine

-

Drying Oven

-

Pouch Cell Making Case Forming Machine

-

Vacuum Chamber Standing Box

-

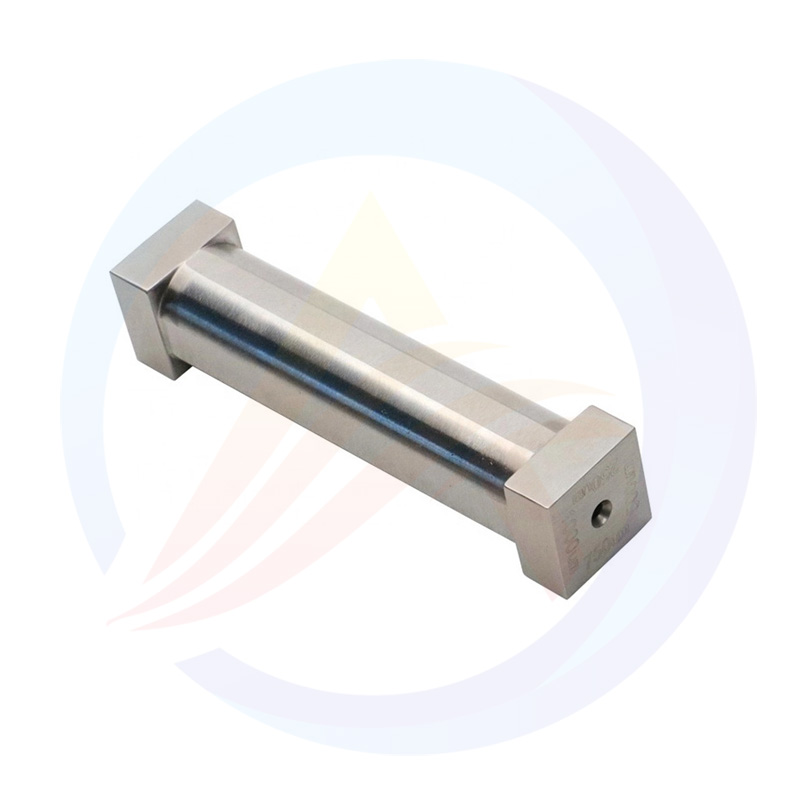

powder press machine

- Battery Raw Materials

-

Other Battery Machine

-

News

- Case

- Factory Show

- About Us

-

Videos

-

Contact Us