I. What is a Coin Cell Crimper?

A Coin Cell Crimper is a specialized device that uses mechanical pressure to tightly press the outer shell (positive electrode shell) of a coin cell battery against the sealing structure (negative electrode cap,sealing ring) to achieve battery sealing. Its working principle is based on the "plastic deformation sealing" technology:by applying uniform pressure to the edge of the battery shell through a mold, the shell and the sealing ring form an interference fit, blocking the leakage channel of the electrolyte while avoiding excessive squeezing that could damage the internal electrode structure.

Based on application scenarios and the degree of automation, Coin Cell Crimpers are mainly divided into three categories:

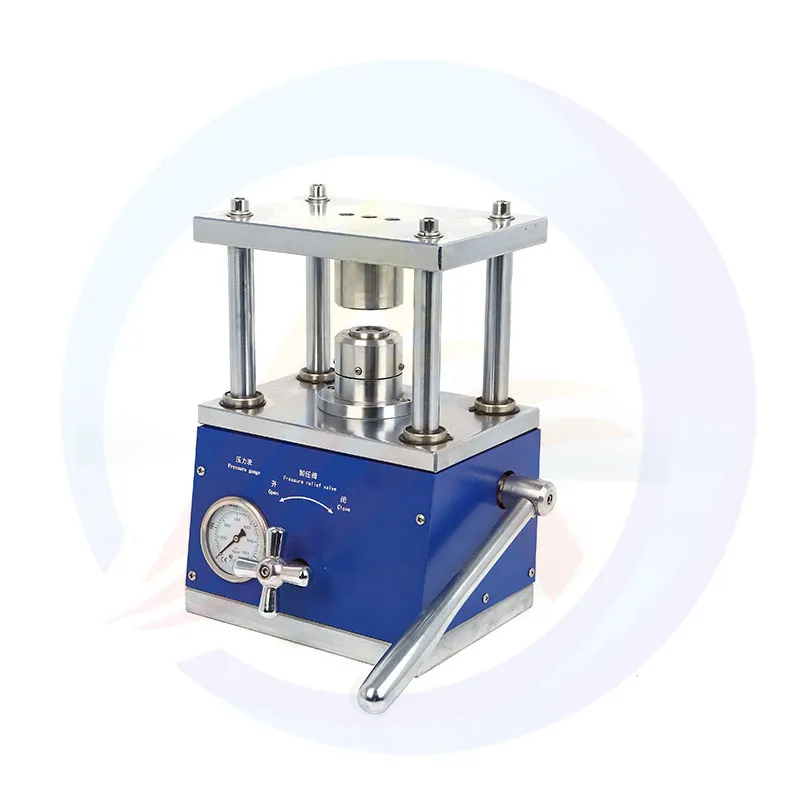

Manual crimping machines: These are compact in size and rely on manual rotation of a handle or pressing of a lever to provide pressure, with a pressure range typically between 0-5kN. Such equipment is suitable for small-batch sample preparation in laboratories, such as the assembly of coin cells during the material research and development stage.

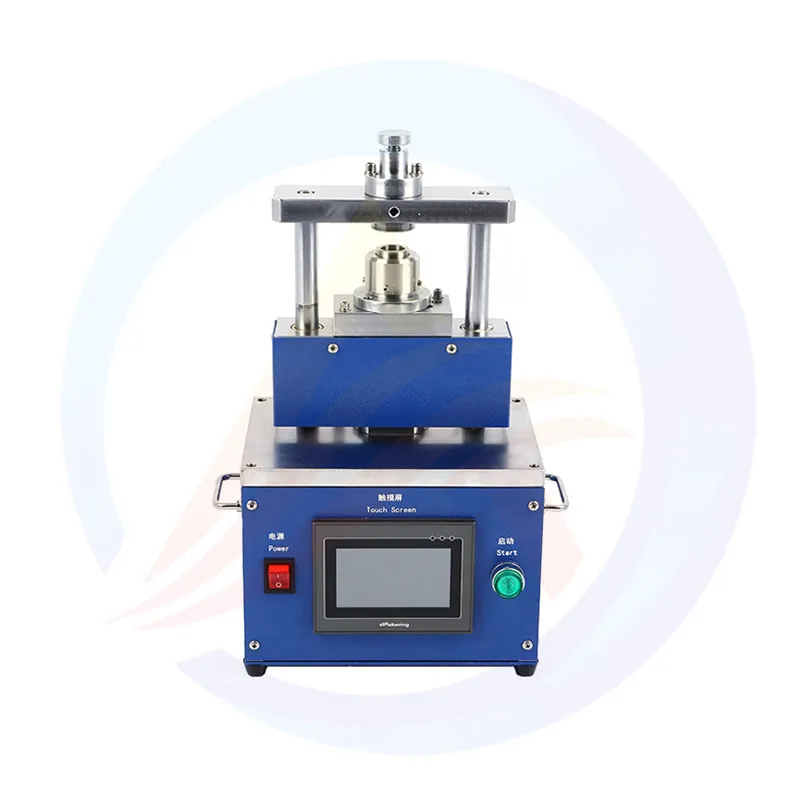

Semi-automatic edge pressing machine: Equipped with an electric or pneumatic drive system, the pressure can be set through a digital panel, with an accuracy of ±0.1kN. It supports single-station continuous operation, with an edge pressing efficiency of 10-30 pieces per hour, suitable for pilot lines or small-scale production scenarios.

Fully automatic crimping machine: Integrating the entire process of feeding, positioning, crimping, and inspection into a fully automated system, it is equipped with a visual positioning system, achieving an accuracy of ±0.01mm. It features a pressure closed-loop control function and can produce 100-500 cells per hour. It is widely used in the large-scale production of button cells for consumer electronics and medical devices.

II. Core Functions of the Coin Cell Crimping machine

The unique structure of button cells (small size and high sealing requirements) determines the critical role of the crimping machine, which plays a vital role throughout the battery's "safety - performance - lifespan" cycle. Specifically, it can be divided into three core dimensions:

1. Ensuring sealing safety and eliminating the risk of electrolyte leakage

Electrolyte leakage is the primary cause of button cell failure. The crimping machine ensures a reliable sealing barrier by precisely controlling the three parameters of "pressure - crimp depth - crimping speed":

Physical sealing: The crimping die bends the edge of the outer shell inward, tightly compressing the sealing gasket (usually made of PP, PE, or fluororubber) between the positive shell and the negative cover, forming a "metal - rubber - metal" triple sealing structure, with a leakage rate controlled below 0.1%.

Chemical protection: Some high-end crimping machines are equipped with a "pressure feedback adjustment" function. When there are minor defects in the sealing gasket, the equipment automatically adjusts the pressure to compensate, preventing local pressure insufficiency from causing electrolyte contact with air and reducing battery self-discharge, which can be reduced to less than 2% per month.

2. Stabilize electrode structure and enhance battery electrochemical performance

The electrodes (positive electrode, negative electrode, and separator) of button batteries are stacked in a layered structure. The uniformity of pressure during the edge-pressing process directly affects the contact resistance of the electrodes and the efficiency of ion conduction:

Control contact resistance: A high-quality edge-pressing machine with a pressure uniformity of less than 5% can ensure that the electrodes are closely attached to the current collectors, avoiding increased contact resistance due to local gaps. Typically, the contact resistance can be stabilized below 50 mΩ, thereby reducing polarization during charging and discharging and improving the battery's rate performance. For example, the 1C discharge capacity retention rate can increase from 85% to 95%.

Protect the integrity of the separator: The "soft start" function of the edge-pressing machine can prevent excessive instantaneous pressure from causing the separator to rupture (the separator is usually only 10-20 μm thick), preventing direct contact between the positive and negative electrodes and causing short circuits, thereby enhancing the battery's cycle life.

3. Adapt to multiple specifications and meet diverse application scenarios

Button batteries in different fields (such as 3V lithium manganese battery CR2032, lithium iodide batteries for medical use) have significant size differences (diameter: 6-20mm, thickness: 1-5mm). The crimping machine needs to have flexible adaptability:

Mold compatibility: Support quick mold replacement, with a replacement time of less than 5 minutes, and be able to adapt to button battery shells of different diameters and thicknesses. Some devices can also be compatible with customized molds, such as special molds for irregular-shaped button batteries.

Parameter adjustability: Adjust the crimping pressure (0-20kN), crimping depth (0-2mm), and crimping speed (5-50mm/min) through a digital control system to meet the crimping requirements of different material shells (such as aluminum shells, stainless steel shells), avoiding shell deformation, with the deformation controlled within 0.05mm.

III. How to Select a Coin Cell Crimper?

When selecting a Coin Cell Crimper, it is necessary to make a comprehensive judgment based on application scenarios (laboratory / pilot production / mass production), battery specifications, performance requirements, and other factors. The following provides selection criteria from five core dimensions and offers specific suggestions for different scenarios:

1. Core selection dimensions: Comprehensive assessment from performance to cost

In terms of pressure control accuracy, key indicators include pressure range, non-uniformity, and repeatability. High-quality equipment typically has a pressure range of 0-20kN, with non-uniformity less than 5% and repeatability reaching ±1%. It is important to note that in laboratory settings, devices with high precision (±0.1kN) should be prioritized, while in mass production scenarios, a balance must be struck between precision and efficiency.

For the mold system, key indicators are mold material and ease of replacement. High-quality molds are often made of hard alloys, with wear resistance exceeding 5000 times per set and replacement time under 5 minutes. When purchasing, ensure that the mold is compatible with the target battery specifications.

2. Scene-specific selection recommendations: Precise matching of needs to avoid resource waste

Laboratory R&D scenario (monthly output < 1000 pieces):

The core requirements are small-batch production, multi-specification compatibility, and high-precision crimping. It is recommended to choose manual or semi-automatic crimping machines, with a focus on equipment pressure accuracy (reaching ±0.1kN) and mold compatibility.

Pilot line scenario (monthly output 10,000 - 100,000 pieces):

The core requirement is to balance production efficiency and equipment flexibility. It is recommended to choose semi-automatic crimping machines, which should be equipped with an electric drive system (capacity reaching 20-30 pieces per hour) and pressure feedback adjustment function.

Large-scale production scenario (monthly output > 100,000 pieces):

The core requirements are high capacity, high stability, and full automation. It is recommended to choose fully automatic crimping machines, which should integrate a visual positioning system (accuracy ±0.01mm), online leakage detection function (detection efficiency 100%), and MES system integration function.

In summary, the selection of Coin Cell Crimpers should follow the principle of "demand-oriented, performance-first, and cost-appropriate". Whether in laboratory R&D or large-scale production, only by precisely matching equipment performance with actual needs can the quality of button batteries be guaranteed while achieving the optimal balance between efficiency and cost.