Disc Punching Machine can efficiently produce circular discs of battery electrodes and separators, and is suitable for the research and development of various coin cells. Through the study of its precision control, material compatibility, and operational convenience, the adaptability of this equipment in scenarios such as small-batch sample preparation in battery laboratories and TEM sample pretreatment is verified, providing technical references for the selection of precision processing equipment in the field of battery research and development.

1. Introduction

In the research and development process of new energy storage devices such as lithium-ion batteries and solid-state batteries, the dimensional accuracy of electrodes and separators directly affects the assembly efficiency, electrochemical performance, and safety of batteries. Due to their compact structure, low sample consumption, and convenient testing, coin cells have become the core carrier for evaluating battery material performance and studying interface reactions. However, the processing of electrode and separator circular discs for coin cells requires meeting the technical requirements of "no burrs, no dents, and high dimensional consistency". Traditional methods such as scissors cutting and ordinary stamping equipment processing are prone to cause material edge damage and excessive dimensional deviation, which in turn lead to problems such as battery short circuits and capacity fading.

2. Structural Design and Technical Advantages of Precision Punchers

2.1 Core Structural Design

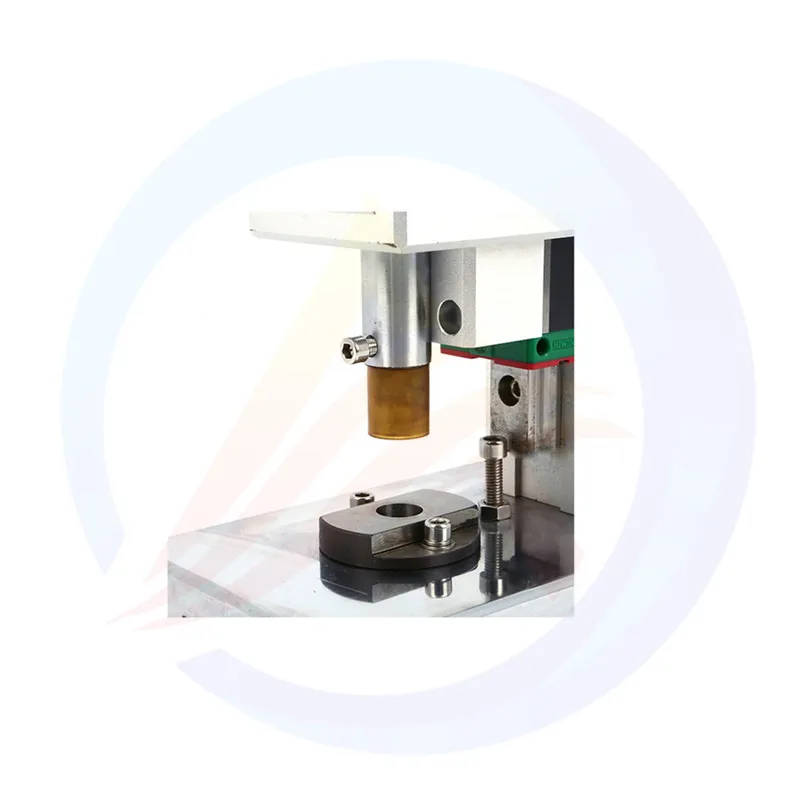

The structural design of precision punchers revolves around three core requirements: "precision, portability, and durability". They adopt high-quality ball-bearing slide rails instead of traditional sliding slide rails, which can reduce lateral deviation during the punching process, ensure that the coaxiality error between the punch and the die remains at a low level, and thus guarantee the dimensional consistency of the punched circular discs from the structural perspective. At the same time, the smoothness of the slide rails reduces the resistance of manual operation, improves the stability of a single punching, and avoids material wrinkling or edge damage caused by uneven force application.

The body is made of fully anti-corrosion materials, featuring "permanent rust prevention". The electrolytes and cleaning reagents commonly used in battery laboratories are likely to corrode metal equipment. However, the anti-corrosion body can prevent the equipment from structural loosening and precision degradation due to chemical corrosion, prolong the service life of the equipment, and at the same time ensure that the processed samples are not contaminated by rust impurities from the body.

The equipment is equipped with a standardized die interface, supporting the rapid replacement of customized dies within a certain range. The positioning of the die and the punch adopts a "pin-hole fit" design. When replacing the die, no additional calibration is required, and the switch from electrode punching to separator punching can be completed quickly, meeting the demand for rapid preparation of multi-specification samples in the laboratory.

2.2 Analysis of Technical Advantages

Compared with traditional battery disc processing equipment, precision punchers have significant technical advantages. In terms of high-precision processing capability, the edges of the circular discs punched by the equipment are free of burrs and dents, and the dimensional tolerance is controlled within a small range. For battery electrodes, edge burrs are likely to pierce the separator and cause short circuits, and excessive dimensional tolerance will affect the electrolyte wetting effect. The high-precision processing capability of this equipment can effectively avoid these risks.

In terms of material compatibility, the equipment can be adapted to thin metal foils and separators of different thicknesses. Different battery systems have significant differences in material thickness requirements, and the wide thickness adaptation range of this equipment can cover the processing needs of mainstream battery systems.

The equipment is small in size and light in weight, belonging to "miniaturized laboratory equipment", and can be placed into a glove box for operation through a transition chamber of a specific diameter. In battery research and development, some sensitive materials need to be processed in an inert gas atmosphere. The glove box adaptability of the equipment enables "in-situ processing" of sensitive materials, ensuring the chemical stability of the samples.

In addition, the equipment adopts a "manual pressing" operation mode, without the need for an external power supply or compressed air, and the operation process is simple. Even researchers without professional equipment operation experience can master it proficiently after short-term training. Its compact structure can be directly placed in narrow spaces such as laboratory fume hoods and glove box operation platforms, without occupying additional space.

3. Application Scenarios of Precision Punchers in Battery Research and Development

3.1 Standardized Preparation of Coin Cells

The structure of a coin cell consists of "negative electrode case - negative electrode - separator - positive electrode - shim - positive electrode case". Different models of coin cells have clear requirements for the sizes of electrodes and separators. The electrode circular discs processed by the precision puncher can form a reasonable assembly gap with the positive and negative electrode cases of different models of coin cells, which not only avoids direct contact between the electrode and the case but also ensures that the electrolyte can fully wet the electrode material. At the same time, the processed separator circular discs can completely cover the positive and negative electrodes, effectively blocking the electronic conduction between the positive and negative electrodes and preventing battery short circuits.

3.2 Evaluation of Battery Material Performance

In the research and development of battery materials, the electrochemical performance testing of materials needs to be based on "electrodes with consistent sizes". Otherwise, it is difficult to distinguish whether the performance difference is caused by the material itself or processing errors. The high-precision processing capability of the precision puncher can realize the precise control of the active material loading. The active material loading of the electrode is related to the electrode area. The electrode circular discs processed by the equipment have small dimensional deviation, corresponding to small area deviation, and the loading calculation error can be controlled within a low range, which is much lower than that of the traditional cutting method, ensuring the accuracy of the material specific capacity calculation.

In the comparative study of separator performance, the performance of the separator, such as air permeability and mechanical strength, needs to be indirectly evaluated through coin cell testing, and the dimensional consistency of the separator directly affects the repeatability of the test results. The separator circular discs processed by the precision puncher can ensure that the area and edge state of the separator are consistent in each test, improving the comparability of experimental data.

4. Precautions for Equipment Use and Maintenance Suggestions

4.1 Precautions for Use

When using the equipment, the material thickness must be strictly controlled, and the punching thickness range specified by the equipment must be followed. For metal foils exceeding the upper thickness limit, forced punching may cause punch deformation and die damage; for overly thin separators, a thin layer of paper should be placed under the material to prevent the separator from sticking to the punch after punching.

When using the equipment inside the glove box, it should be slowly placed into the glove box through the transition chamber to avoid slide rail deviation caused by the equipment colliding with the inner wall of the glove box. At the same time, the inert gas atmosphere inside the glove box may reduce the lubricity of the equipment's slide rails. A small amount of vacuum grease can be regularly applied to the slide rails to keep them smooth.

After each use, the surface of the die should be wiped with a dust-free cloth dipped in ethanol to remove residual electrode materials or separator debris, so as to avoid the reduction of punching precision caused by debris accumulation. When the die is not in use for a long time, it should be stored in a dry box to prevent rusting or contamination by dust.

4.2 Maintenance Suggestions

It is recommended to calibrate the precision of the equipment once every 6 months. Standard gauge blocks are used to measure the actual punching size of the die. If the dimensional deviation exceeds the specified range, the positioning pin between the punch and the die should be adjusted, or the manufacturer should be contacted for professional calibration.

The surface of the slide rails should be cleaned of dust and impurities every month, and a small amount of special slide rail lubricating oil should be applied to avoid wear caused by dryness of the slide rails; if the slide rails are found to be stuck, use should be stopped immediately, and check whether there is foreign matter stuck or the slide rails are deformed.

The punch and die of the equipment are wearing parts. After long-term use, the cutting edge may be worn, resulting in burrs on the edge of the punched circular disc. It is recommended to replace the punch and die regularly according to the number of punching times to ensure the processing precision.