When you charge your smartphone or drive an electric vehicle (EV), you rarely think about the tiny, precise steps that go into making its battery. Yet, two humble tools—battery applicator and coaters—are critical to creating the thin, uniform electrode layers that determine a battery’s energy density, lifespan, and safety. As global demand for batteries surges (the International Energy Agency predicts 10x growth by 2030), these "behind-the-scenes" tools are getting smarter and more precise. This science popularization piece breaks down what battery applicator and coaters do, how they work, and why they matter to every device powered by a battery.

What Are Battery applicator & Coaters, and Why Do They Exist?

Battery electrodes—whether the anode (negative side, often graphite) or cathode (positive side, like NMC or LFP)—start as a thick, paste-like "slurry." This slurry mixes active materials (e.g., lithium iron phosphate for cathodes), conductive additives (e.g., carbon black), and binders (e.g., PVDF) in a solvent. To turn this slurry into a functional electrode, two steps are non-negotiable:

Mixing & Prep with applicator s: applicator ensure the slurry is evenly mixed, free of lumps, and has the right consistency.

Coating with Coaters: Coaters spread the slurry onto a thin metal current collector (copper for anodes, aluminum for cathodes) to form a smooth, consistent layer—usually just 5–100 micrometers thick (thinner than a human hair!).

Battery applicators: The "Mix Masters" of Battery Slurry

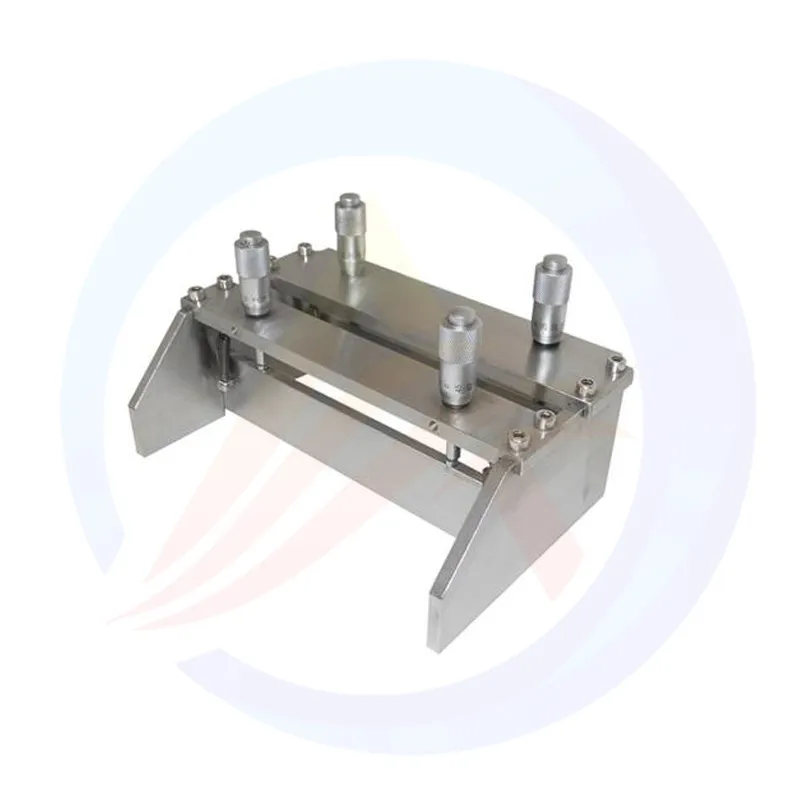

Battery applicator (also called "dispersion applicator s" or "mixing blades") are designed to break up clumps, distribute additives evenly, and control the slurry’s viscosity (thickness). Think of them as high-tech spatulas— but built for industrial precision.

How They Work?

Most battery labs and factories use rotary applicator s attached to mixing tanks. As the tank spins, the applicator ’s flexible or rigid blade presses against the tank wall, scraping off dried or clumped slurry that would otherwise ruin the mix. At the same time, internal blades (often shaped like propellers or helices) stir the slurry, while the applicator ensures no material sticks to the tank—critical for consistent results.

Key features of a good battery applicator :

Material Compatibility: Blades are made of wear-resistant materials like stainless steel, Teflon, or ceramic. Teflon applicator are ideal for acidic slurries (e.g., those with sulfuric acid), while ceramic applicator handle abrasive materials (e.g., silicon-based anode slurries) without scratching the tank.

Adjustable Pressure: applicator can be tuned to apply 0.5–5 Newtons of pressure—enough to remove clumps but not so much that they damage the tank or shear (break apart) delicate active materials like NMC particles.

Speed Sync: The applicator ’s rotation speed is synced with the mixer (usually 50–500 RPM) to avoid creating air bubbles. Bubbles in the slurry lead to holes in the electrode, which cause short circuits.

Types of applicator for Different Slurries

Rigid applicator (Stainless Steel): Used for thick, high-viscosity slurries (e.g., LFP cathode slurries with 60% solid content). Their stiff blades push through dense material to ensure even mixing.

Flexible applicator (Teflon-Coated): Perfect for low-viscosity slurries (e.g., graphite anode slurries). The flexible blade conforms to the tank’s shape, leaving no residue behind.

Dual-Action applicator s: Combine a rigid inner blade for mixing and a flexible outer blade for scraping—used in advanced labs testing new slurry formulas (e.g., sodium-ion battery slurries with unusual additives).

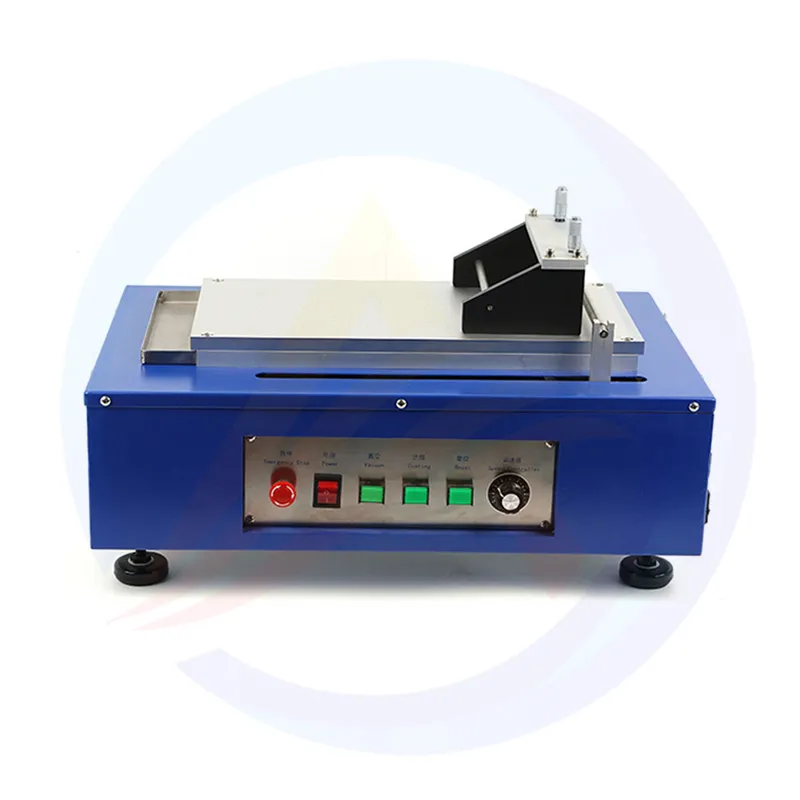

Battery Coaters: Turning Slurry into Uniform Electrode Layers

Once the slurry is mixed, battery coaters take over. Their job is to spread the slurry onto a current collector (e.g., a roll of copper foil) in a layer that’s consistent in thickness, smooth, and free of defects. This is one of the most precise steps in battery manufacturing—even a 1-micrometer error can rui n an electrode.

Lab coaters are small (about the size of a laptop) and easy to adjust—critical for testing new materials. For example, a researcher testing a silicon-graphite anode can swap rods to try 5, 10, or 15-micrometer layers, then measure how thickness affects capacity and cycle life.

Industrial Coaters (For Mass Production)

Factories use slot-die coaters—large, automated machines that coat miles of current collector foil per hour. Here’s the process:

The slurry is pumped into a "slot die" (a narrow, precision-machined opening) above a moving roll of foil (e.g., 1-meter wide copper foil moving at 1–5 meters per second).

The die releases a controlled amount of slurry onto the foil, while a "doctor blade" (a thin metal strip) trims the top of the layer to ensure uniform thickness.

Sensors (laser or ultrasonic) monitor the layer in real time—if thickness varies by more than 0.5 micrometers, the machine adjusts the die pressure or foil speed automatically.

Why These Tools Are Critical for Better Batteries?

applicator and coaters might seem simple, but they directly impact three key battery performance metrics:

Energy Density: A uniform electrode layer means more active material can be packed into the battery (no gaps from bubbles or lumps). For example, a well-coated NMC cathode can hold 20% more lithium ions than a lumpy one—boosting an EV’s range by 100+ kilometers.

Cycle Life: Uneven layers cause stress during charging (some areas expand more than others), leading to electrode cracking. A study by Stanford University found that electrodes made with precision coaters retained 90% of their capacity after 1,000 cycles, compared to 65% for poorly coated ones.

Safety: Hot spots from uneven layers are a leading cause of battery fires. Coaters with real-time sensors eliminate these hot spots, making batteries safer for EVs and smartphones.

Innovations Making applicator & Coaters Better

Battery applicator and coaters are the unsung heroes of energy storage. Without their precision, the lithium-ion batteries powering our phones, cars, and grids would be less efficient, shorter-lived, and less safe. As we move to next-generation batteries—solid-state, sodium-ion, lithium-sulfur—these tools will only become more important. They’re a reminder that big innovations often depend on small, precise tools: the ones that turn messy slurry into the perfect layers powering our future.

Whether you’re a researcher testing a new electrode material in a lab or a factory worker making EV batteries, applicator and coaters prove that "perfect" isn’t an accident—it’s a result of tools designed to get every micrometer right.