In the era of rapid technological development, batteries, as the core power source of numerous electronic devices and new energy systems, their performance directly affects the breadth and depth of technological applications. Among the large family of battery materials, LiMn2O4 powder is gradually emerging as a focus of attention.

Basic Characteristics of LiMn2O4 Powder

LiMn2O4 Powder, with the Chinese name lithium manganate, usually appears as a black - gray powder and belongs to a spinel - type structure, having a unique crystal configuration. From a crystallographic perspective, it is a typical ionic crystal with both normal and inverse configurations. The normal spinel LiMn2O4 powder has a cubic crystal structure with Fd3m symmetry. Its unit cell constant a = 0.8245nm, unit cell volume V = 0.5609nm³. Oxygen ions are in a face - centered cubic close - packed arrangement, lithium occupies 1/8 of the oxygen tetrahedral interstitial positions, and manganese occupies 1/2 of the oxygen octahedral interstitial positions. The unit lattice contains 56 atoms, among which Mn³⁺ and Mn⁴⁺ each account for 50%. This special structure provides a three - dimensional channel for the diffusion of lithium ions, which is formed by the coplanar arrangement of tetrahedral lattice 8a, 48f and octahedral lattice 16c, enabling lithium ions to be reversibly inserted into and extracted from the spinel lattice, which is an important theoretical basis for its use as a battery cathode material.

Theoretically, the specific capacity of LiMn2O4 powder can reach 148mAh/g, having a certain potential for energy storage. However, in practical applications, its performance is restricted by some factors. For example, its cycle performance is relatively poor, and the battery capacity is prone to attenuation after multiple charge - discharge cycles; at the same time, its electrochemical stability is not good, especially in high - temperature environments, this deficiency is more obvious. These problems have to some extent limited the large - scale industrial application of LiMn2O4.

Application Fields of LiMn2O4 Powder

Despite some performance shortcomings, LiMn2O4 powder still shows strong application potential in many fields relying on its unique advantages. At present, its most important application field is the cathode material of lithium - ion batteries for portable electronic devices. In the mobile phones, laptops and other devices we use daily, the battery cathodes constructed with LiMn2O4 powder provide indispensable power support for the stable operation of the devices.

In addition to portable electronic devices, LiMn2O4 powder is also widely used in the field of power tools. Power tools such as electric screwdrivers and electric drills require batteries to have good high - current discharge performance. The good high - current charge - discharge performance of LiMn2O4 enables it to meet the demand of power tools for instantaneous high - power output, ensuring that the tools can work efficiently and stably.

In some fields sensitive to cost, such as low - speed electric vehicles, LiMn2O4 also has advantages. Compared with some other battery cathode materials, LiMn2O4 has abundant resources and low cost, which makes low - speed electric vehicles have more room for battery cost control. At the same time, its relatively good safety provides a certain guarantee for the driving safety of the vehicles.

Preparation Methods of LiMn2O4 Powder

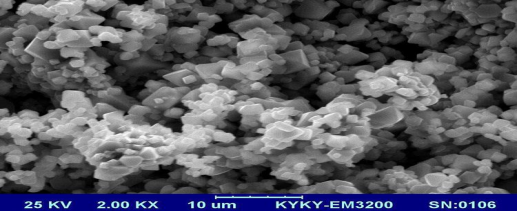

In order to obtain high - performance LiMn2O4 powder, researchers and engineers have developed a variety of preparation methods. Among them, the high - temperature solid - state synthesis method is a commonly used one. This method is relatively simple to operate and easy to realize large - scale industrial production. Its basic principle is to mix raw materials containing lithium sources and manganese sources in a certain proportion evenly, and then carry out a solid - state reaction at high temperature to synthesize LiMn2O4 powder . However, this method also has some disadvantages, such as the high reaction temperature required, which leads to high energy consumption; moreover, the synthesized material particles are often large, with poor uniformity, and finally the specific energy of the material is low.

In addition to the high - temperature solid - state synthesis method, there are also melt impregnation method, microwave synthesis method, sol - gel method, emulsion drying method, co - precipitation method, Pechini method and hydrothermal synthesis method, etc. Taking the Pechini method as an example, this method improves the traditional process by pre - igniting the precursor during the synthesis process, thus effectively improving the uniformity of LiMn2O4 powder. With the increase of EG (ethylene glycol) content, the uniformity of the powder is improved, the specific surface area is increased, and the cycle performance is also improved. The samples calcined at 800℃ for 4 hours have charge - discharge specific capacities of 130.7mAh/g and 126.7mAh/g respectively. Different preparation methods have their own advantages and disadvantages. In practical applications, it is necessary to choose a suitable preparation process according to specific needs and production conditions.

Development Prospect of LiMn2O4 Powder

Facing the problems of cycle performance and electrochemical stability of LiMn2O4, researchers are actively exploring solutions. On the one hand, surface modification technology can effectively inhibit the dissolution of manganese and the decomposition of electrolyte, thus improving the stability of the material. On the other hand, doping specific elements can inhibit the Jahn - Teller effect during charge and discharge, further improving the performance of the material. The combination of surface modification and doping technology is expected to become an important research direction to improve the electrochemical performance of spinel LiMn2O4 in the future.

From the perspective of market prospects, with the continuous growth of global demand for new energy, the battery industry has ushered in unprecedented development opportunities. LiMn2O4, with its advantages of abundant resources and low cost, is expected to occupy a larger share in the future battery material market. Especially in application scenarios with high requirements for cost and safety, LiMn2O4 powder, after performance optimization, will have stronger competitiveness. For example, in the field of large - scale energy storage, if its existing problems can be solved, LiMn2O4 will provide an efficient, economical and safe battery material option for energy storage systems.

As a battery material with important potential, LiMn2O4 powder, although facing some challenges at present, with the continuous progress and innovation of technology, its performance will be continuously improved, and its application fields will be further expanded. It is expected to play a more important role in the development of the battery industry in the future and contribute to promoting technological progress and energy transformation.