Battery Vacuum Mixer Machine

Battery vacuum mixer machines are specialized equipment used in the mixing of battery materials, particularly in the production of lithium-ion batteries.

These machines operate under vacuum conditions to ensure that the mixing process is free from contamination and to enhance the quality of the mixed materials.

Key Features of Battery Vacuum Mixer Machines

1. Vacuum Environment:

Operates under vacuum to prevent contamination.

Helps in achieving a more homogeneous mix.

2. Mixing Mechanism:

Typically employs planetary mixing or other advanced mixing technologies.

Ensures thorough mixing of battery materials.

3. Material Compatibility:

Designed to handle a wide range of battery raw materials.

Suitable for mixing slurries, powders, and other materials used in battery production.

4. Controllability:

Offers precise control over mixing parameters such as speed, time, and temperature.

Allows for customization of mixing processes to meet specific battery production needs.

5. Durability and Reliability:

Constructed with high-quality materials to ensure long-term durability.

Designed for continuous operation in industrial settings.

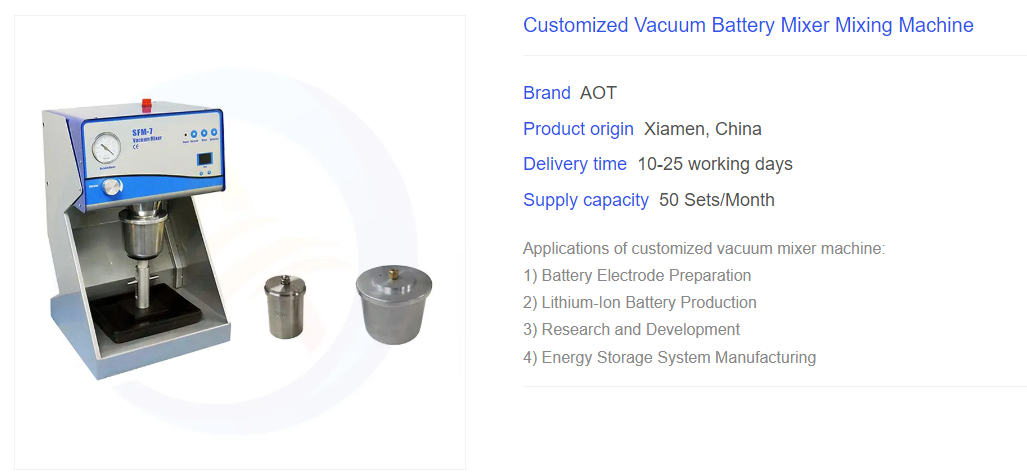

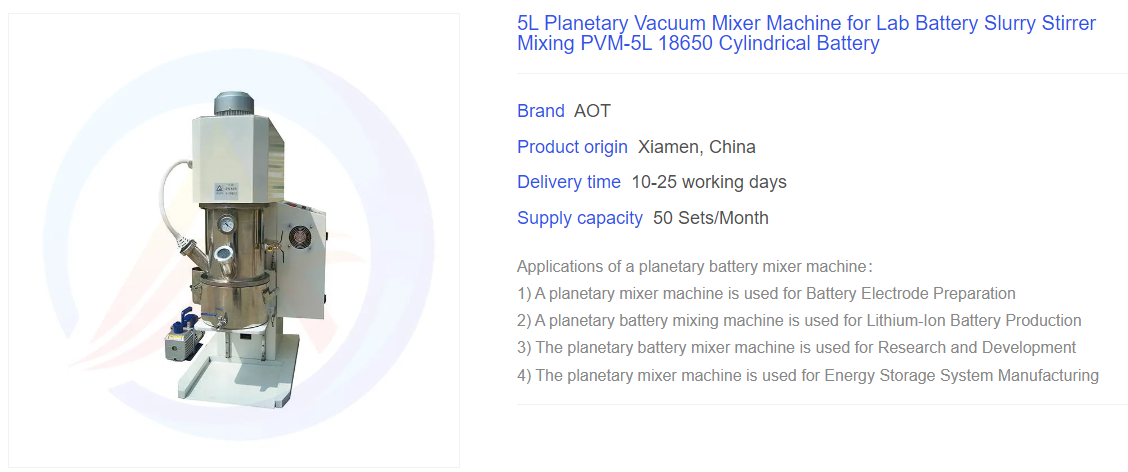

There are various types of battery vacuum mixer machines available, including:

These machines use planetary mixing technology, where the mixing blades move in a complex pattern to ensure thorough mixing.

Suitable for small to medium-sized batches.

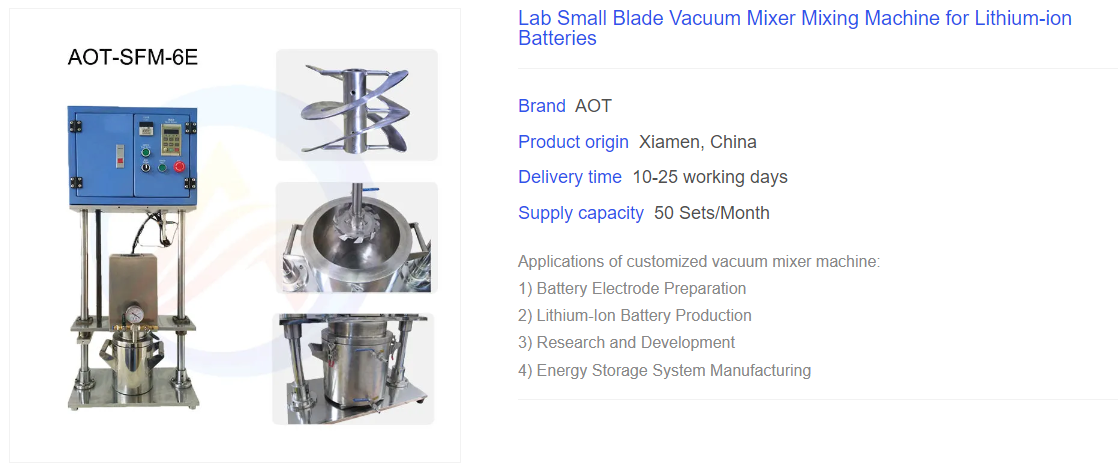

2. Helical Blade Vacuum Mixers:

Feature helical blades that spiral through the material, providing effective mixing action.

Often used for mixing viscous materials.

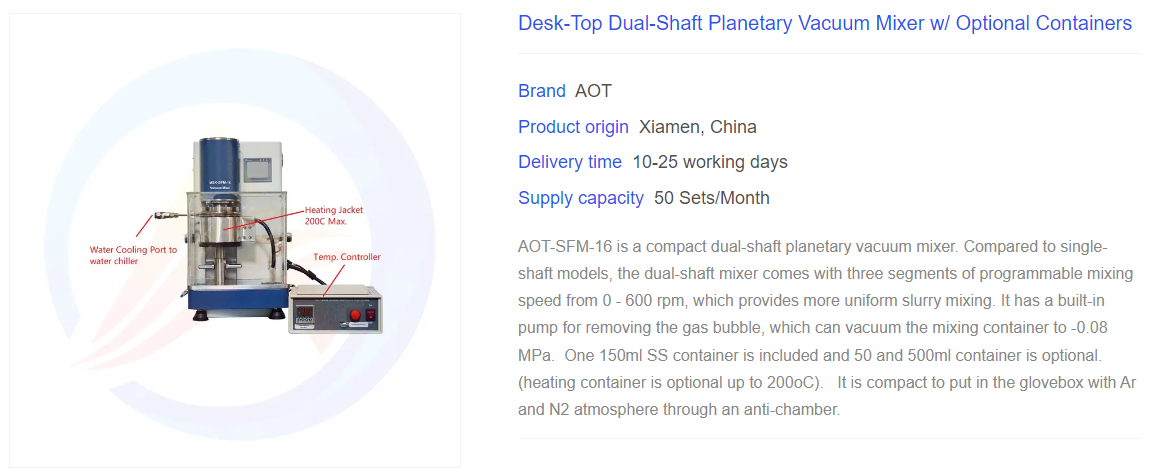

Equipped with two mixing shafts that rotate in opposite directions.

Provides high shear mixing action, suitable for difficult-to-mix materials.

Battery vacuum mixers are versatile equipment primarily used for mixing various materials in a vacuum environment.

Here's an introduction to the materials that battery vacuum mixers are suitable for mixing:

1. Polymer Lithium-ion Battery Liquids and Liquid Lithium-ion Battery Liquids:

These are common applications for battery vacuum mixers.

The vacuum mixing process ensures the uniformity and stability of the battery liquids, thereby enhancing battery performance.

2. Electronic Battery Pastes:

Including positive electrode pastes and negative electrode pastes, these pastes require precise control of their composition and uniformity to ensure battery quality and performance.

Battery vacuum mixers can meet these requirements and achieve uniform mixing of the pastes.

3. Adhesives, Mold Release Agents, Carbonyl Sealants, Polyurethane Sealants, etc.:

These materials often have high viscosity and fluidity, requiring vacuum mixing to ensure their mixing uniformity.

4. Anaerobic Adhesives, Paints, Inks, Pigments:

These materials are prone to generating bubbles during the mixing process. Battery vacuum mixers can effectively remove these bubbles through vacuum operations, improving mixing effects.

5. Cosmetics, Ointments:

These materials have high requirements for mixing uniformity and fineness. Battery vacuum mixers can meet these requirements, ensuring product quality and stability.

In addition, battery vacuum mixers are also suitable for mixing, reacting, dispersing, dissolving, homogenizing, and emulsifying various liquid-liquid and solid-liquid materials in other industries such as electronics,chemicals, pharmaceuticals, pesticides, and building materials.

In summary, battery vacuum mixers have a wide range of applications and can be used for mixing multiple materials.

When selecting and using battery vacuum mixers, it is essential to choose the appropriate equipment model and parameters based on the characteristics of the materials and mixing requirements.

Regular maintenance and servicing of the equipment are also crucial to ensure its long-term stable operation.