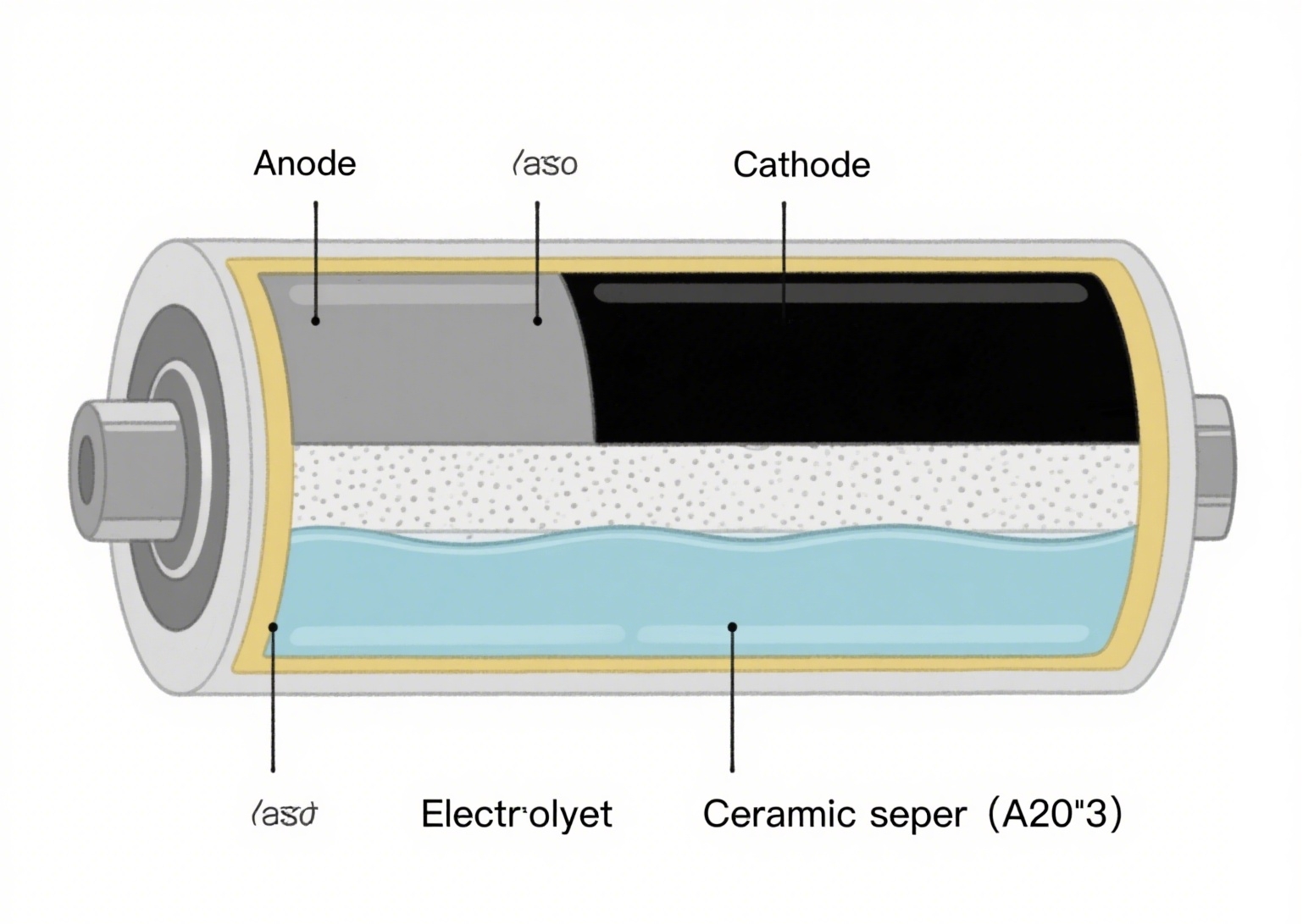

In the intricate architecture of modern batteries, battery separator play a silent yet critical role: they physically isolate the anode and cathode while enabling ion transport, a balance that directly impacts safety, efficiency, and longevity. Among the diverse materials used for battery separator , ceramic-based options have emerged as game-changers, particularly in high-performance applications like electric vehicles (EVs) and grid storage. This article explores the composition, advantages, manufacturing, and future potential of ceramic battery separator, highlighting their transformative role in next-generation energy storage systems.

What Are Ceramic Battery Separator?

Ceramic are thin, porous membranes designed to prevent electrical short circuits between a battery’s anode and cathode while facilitating the movement of ions (e.g., lithium or sodium) during charge-discharge cycles. Unlike traditional polymer separators (e.g., polyethylene or polypropylene), they incorporate ceramic materials—typically metal oxides, nitrides, or sulfides—either as coatings on polymer substrates or as standalone ceramic films.

The ceramic component is the key differentiator. Common ceramics used include:

Alumina (Al₂O₃): Valued for its high thermal stability and mechanical strength.

Silica (SiO₂): Enhances wettability with electrolytes, improving ion conductivity.

Titania (TiO₂): Offers chemical inertness and resistance to electrolyte corrosion.

Zirconia (ZrO₂): Provides exceptional thermal resistance, critical for high-temperature applications.

These ceramics are often combined with polymers like polyvinylidene fluoride (PVDF) or cellulose to balance rigidity with flexibility, creating hybrid battery separators that retain the best properties of both materials.

Core Advantages of Ceramic Battery Separator

Ceramic separators address longstanding limitations of polymer-based alternatives, making them indispensable in demanding battery systems.

1. Superior Thermal Stability

Polymer separators typically melt at 130–160°C, a critical vulnerability during thermal runaway—a self-sustaining exothermic reaction triggered by overcharging, short circuits, or mechanical damage. Ceramic materials, by contrast, maintain structural integrity at temperatures exceeding 1000°C. For example:

Alumina-coated separators remain stable at 200°C, preventing direct contact between electrodes even as polymers soften.

Zirconia-based separators withstand 1500°C, making them ideal for high-voltage batteries prone to localized heating.

This thermal resilience drastically reduces fire risks, a key reason battery separator play a silent yet critical role: they physically isolate the anode and cathode while enabling ion transport, a balance that directly impacts safety are standard in EV batteries (e.g., Tesla’s 4680 cells) and energy-dense consumer electronics.

2. Enhanced Mechanical Strength

Ceramics add rigidity to separators, reducing puncture risks from dendrites—needle-like metal deposits that form on anodes during cycling. In lithium-ion batteries, lithium dendrites can pierce polymer separators, causing short circuits. Ceramic layers act as a physical barrier:

A 5–10 μm alumina coating on a polyethylene separator increases puncture resistance by 300%, according to tests by LG Energy Solution.

3. Improved Electrolyte Compatibility

Ceramic surfaces are highly polar, enhancing wettability with liquid electrolytes. This ensures uniform electrolyte distribution, reducing internal resistance and boosting ion conductivity.

4. Chemical Inertness

Ceramics resist degradation from aggressive electrolytes, such as the high-concentration electrolytes used in 4.5V+ lithium-ion batteries. This stability extends battery lifespan:

Titania-coated separators in NMC (nickel-manganese-cobalt) batteries retain 90% capacity after 1000 cycles, versus 75% for uncoated separators.

Alumina separators in lithium-sulfur batteries mitigate polysulfide shuttling—a major cause of capacity fade—by adsorbing sulfur species.

Types of Ceramic Separators and Their Applications

Ceramic separators are categorized based on their structure and integration with polymers, each tailored to specific battery chemistries.

1. Ceramic-Coated Polymer Separators

The most widely used type, these consist of a polymer base (e.g., polyethylene) coated with a thin ceramic layer (1–10 μm). They strike a balance between flexibility (from the polymer) and thermal/mechanical strength (from the ceramic).

2. All-Ceramic Separators

Standalone ceramic membranes, often made from zirconia or alumina, offer maximum thermal resistance but are brittle. They require advanced manufacturing to achieve porosity (30–50%) and thinness (20–50 μm).

3. Ceramic-Polymer Composite Separators

Ceramic nanoparticles (50–200 nm) are dispersed within a polymer matrix (e.g., PVDF or cellulose), creating a homogeneous membrane. This design combines ceramic stability with polymer flexibility.

Manufacturing Processes

The production of ceramic separators involves precision engineering to control porosity, thickness, and ceramic distribution.

1. Sol-Gel Coating

A liquid ceramic precursor (sol) is applied to a polymer substrate via slot-die coating or dip-coating, then cured to form a solid (gel) layer. This method is cost-effective for large-scale production of coated separators.

2. Electrospinning

For composite battery separator a polymer-ceramic solution is electrospun into nanofibers, which are then sintered to form a porous membrane. This creates high surface area structures ideal for electrolyte wettability.

3. Tape Casting

Used for all-ceramic battery separator, ceramic powders (e.g., zirconia) are mixed with binders and solvents, cast into thin tapes, and sintered at 1000–1500°C to densify the structure while maintaining porosity.

Market Trends and Future Innovations

The global ceramic battery separator market is projected to reach $3.2 billion by 2030, driven by EV adoption and solid-state battery development. Key trends include:

Thinner Coatings: 1–3 μm ceramic layers to reduce battery separator thickness, increasing battery energy density.

Emerging research focuses on 2D ceramic materials like graphene oxide or hexagonal boron nitride (hBN), which offer atomic-level thickness and exceptional thermal conductivity. A 2024 study in Nature Energy demonstrated hBN-coated separators that reduce thermal runaway risk in NMC batteries by 70%.

Ceramic battery separator have evolved from niche components to essential elements in high-performance energy storage. By combining thermal stability, mechanical strength, and electrolyte compatibility, they address critical safety and efficiency challenges in batteries. As research advances—from thinner coatings to 2D ceramics—ceramic separators will continue to enable breakthroughs in EV range, grid storage durability, and consumer electronics longevity. In the race to electrify the world, these unassuming membranes are indeed the unsung heroes.