Drying ovens are critical for industries requiring precise moisture control, from lithium battery R&D to medical device sterilization. With advancements in technology, modern models now offer specialized features like vacuum compatibility and ultra-fast heating.

Ⅰ.What Is a Drying Oven?

A drying oven uses controlled heat and airflow to remove moisture or volatile substances from materials. Standard models operate between 40°C–300°C, while advanced variants integrate vacuum systems for oxygen-sensitive processes. These ovens are indispensable in fields like battery manufacturing, pharmaceuticals, and chemical processing.

Three common types of drying ovens in the market.

Convection Drying Ovens:Use forced airflow for rapid, uniform heating.Ideal for bulk industrial drying (e.g., battery components, medical tools).

Vacuum Drying Ovens:Combine heat with reduced pressure to prevent oxidation.Critical for lithium battery material research or moisture-sensitive chemicals.

Gravity Convection Ovens:Natural airflow suits gentle drying of powders or glassware.

Based on the data, performance, and user feedback of the company’s products, here are four recommended drying ovens for industrial and laboratory use:

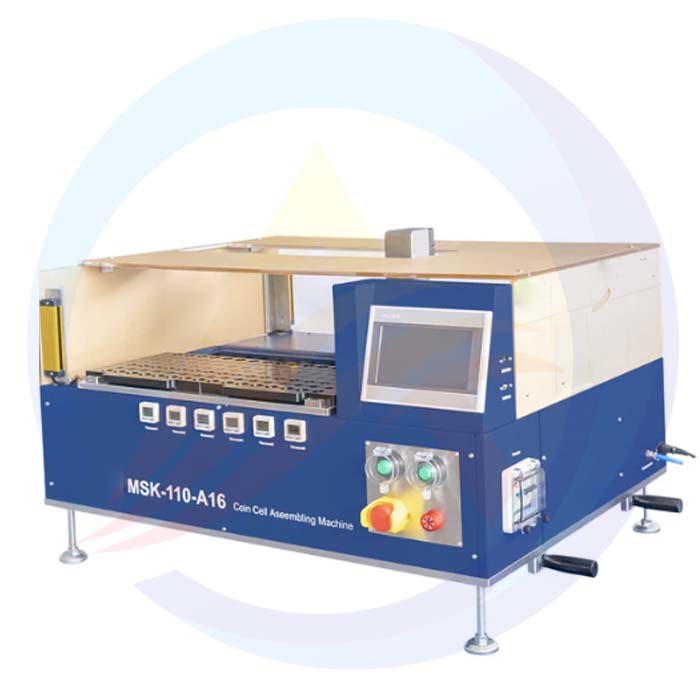

1. 420L Industrial Convection Dry Oven (Digital Control)

Key Specs:420L stainless steel chamber, ±1°C precision.Rapid heating at 10°C/min for time-sensitive workflows.Programmable temperature curves.

Applicable scenarios:High-volume thermal processing in battery manufacturing, chemical labs, or medical device sterilization.

2. AOT-VDO-2 Vacuum Drying Oven (Anti-Corrosion Design)

Key Specs:Cold-rolled steel body with electrostatic spray coating.Stainless steel interior resists rust in humid environments.Vacuum range: 0.1–1000 Pa.

Applicable scenarios:Long-term operation in moisture-heavy labs or electronics drying.

3. Lab 42L Vacuum Drying Oven (Lithium Battery Research)

Key Specs:Heat radiant wall system ensures ±0.5°C uniformity.Compact 42L chamber optimizes lab space.Supports vacuum embedding and plating.

Applicable scenarios:Precision drying of lithium battery electrodes or nanomaterial synthesis.

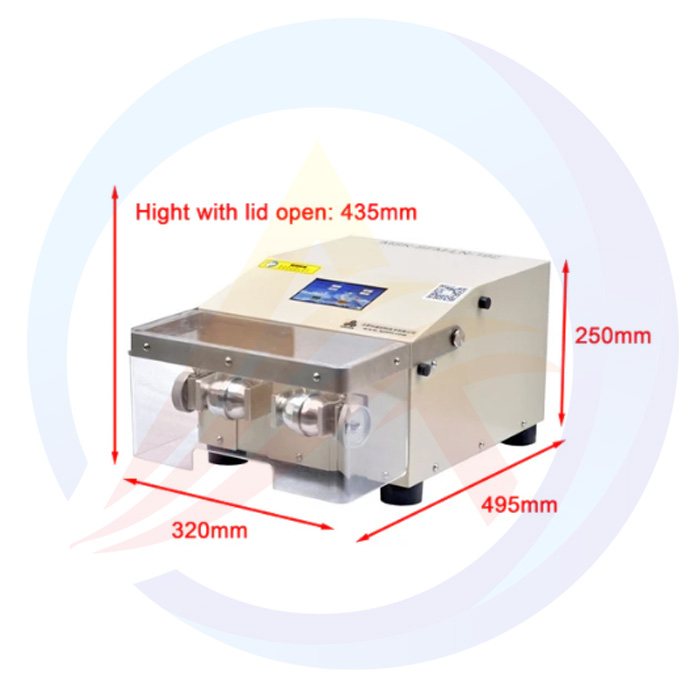

4. 90L Laboratory Vacuum Oven (Battery Material Baking)

Key Specs:Advanced heat radiant technology for uniform temperature distribution.90L capacity balances batch size and footprint.Compatible with inert gas purging.

Applicable scenarios:Baking lithium battery materials (e.g., cathodes, electrolytes) or vacuum curing composites.

Ⅱ.How to Select the Right Drying Oven

Match Capacity to Workload:42L–90L for lab research vs. 420L for industrial batches.

Prioritize Precision:±1°C tolerance suits most tasks, but lithium R&D demands ±0.5°C (see Model 3).

Material Compatibility:Stainless steel chambers (Models 1, 2) resist chemicals; vacuum models (3, 4) prevent oxidation.

Specialized Features:Vacuum systems (Models 2–4) are essential for air-sensitive materials.

Ⅲ.Why Invest in Advanced Drying Ovens?

Accelerate Production: Model 1’s 10°C/min heating slashes processing time.

Enhance Safety: Vacuum ovens minimize fire risks in solvent-heavy environments.

Future-Proof R&D: Radiant wall tech ensures compatibility with next-gen battery materials.

Ⅳ.Conclusion

From industrial-scale convection ovens to compact vacuum units for cutting-edge research, the right drying oven can elevate your operational efficiency.