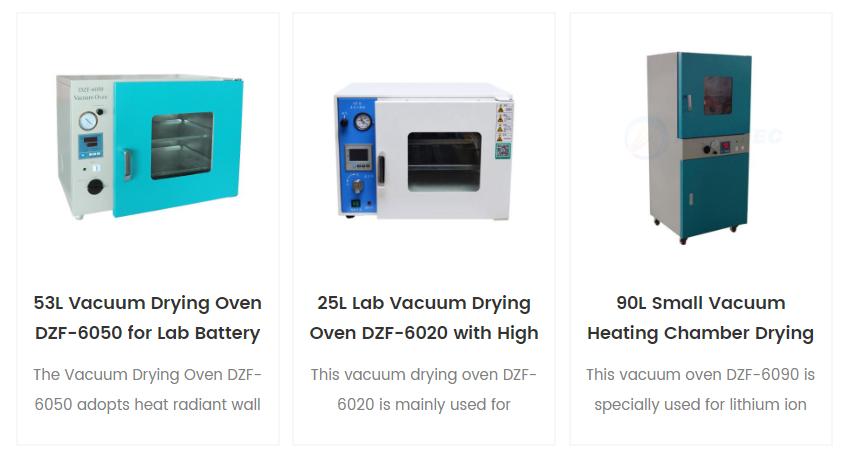

In numerous fields such as scientific research and industrial production, drying technology plays a crucial role and has a significant impact on product quality, production efficiency, and resource utilization. In recent years, with the continuous advancement of technology, various new types of drying equipment have emerged. Among them, the DZF series vacuum drying cabinets have gradually become the highly regarded star products in the market due to their outstanding performance, innovative design, and wide applicability.

The DZF series vacuum drying cabinets are specially designed for drying heat-sensitive, easily decomposable, and easily oxidizable substances. Their working principle is based on operating in a relatively vacuum environment, where the pressure inside the cabinet is reduced, causing the boiling point of the materials to drop. This enables drying operations to be carried out at lower temperatures. This unique working method not only significantly shortens the drying time, improves the drying efficiency, but also effectively avoids the decomposition and oxidation of heat-sensitive substances at high temperatures, thereby maximizing the retention of the original properties of the materials.

From the perspective of product design and manufacturing process, the DZF series vacuum drying cabinets demonstrate an extremely high level. The product shell is made of thickened cold-rolled steel plates and is processed with fine electrostatic spraying treatment. It not only has an elegant and decent appearance, but also has excellent rust prevention and corrosion resistance properties, which can adapt to various complex usage environments. The working chamber is made of high-quality 304 stainless steel plates. This material has good corrosion resistance and easy cleaning properties, ensuring the hygiene conditions inside the chamber and also extending the service life of the equipment. What is worth mentioning is that there are additional reinforcing steel plates around the inner liner, which can effectively ensure that the inner liner does not deform even under long-term vacuum and high-pressure usage, and operates stably and reliably.

In practical use, the numerous features of the DZF series vacuum drying cabinets have brought great convenience to users. The multi-group intelligent PID temperature control system is undoubtedly a major highlight. This system adopts advanced microcomputer design and features precise temperature control, timing, and over-temperature alarm functions. Through intelligent algorithms, it can quickly and accurately control the temperature within the chamber to the set range, with minimal temperature fluctuations, providing a stable environment for the drying process. The control panel uses a color screen liquid crystal display, with clear and intuitive readings. Users can clearly see key information such as the set temperature, actual temperature in the chamber, timing time, and heating status at the same time, facilitating users to monitor the equipment operation in real time and make timely adjustments as needed.

The observation window adopts a double-layer glass door design. This ingenious design not only ensures the good sealing of the cabinet but also allows users to clearly observe the state of the items in the chamber without opening the cabinet door and without affecting the vacuum environment and temperature inside the chamber. Whether observing the changes of samples during experiments or monitoring the drying progress of materials on the production line, this design plays an important role.

The configuration of the digital vacuum pressure gauge is also a major feature of the DZF seriesvacuum drying ovens. Compared with traditional vacuum pressure gauges, the digital vacuum pressure gauge can directly display the pressure value in digital form, with higher accuracy and more convenient and rapid reading. Users can accurately read the pressure value to better control the vacuum degree inside the cabinet, thus meeting the drying requirements of different materials.

In terms of the heating system, the DZF series vacuum drying cabinets adopt a heating method where 4 sets of electric heating tubes surround the outer wall of the inner container. This heating method enables a larger contact area between the electric heating tubes and the inner container, allowing heat to be evenly transferred to the working chamber, effectively improving the temperature uniformity of the vacuum drying cabinet. Whether drying small batches of fine samples or processing large-scale industrial materials, it can ensure that every corner of the materials can be fully and evenly dried, significantly enhancing the consistency of the drying effect.

To ensure good vacuum performance, the cabinet uses high-temperature-resistant silicone rubber sealing rings. This type of sealing ring can still maintain good high-temperature performance in long-term high-temperature environments, without deformation or color change, and the sealing performance remains stable and reliable, ensuring that the internal of the cabinet can maintain a high vacuum degree, providing a strong guarantee for the vacuum drying process.

In terms of the vacuum pump configuration, the vacuum pump of the cabinet is equipped with a return oil prevention device and an impurity filter. This thoughtful design effectively extends the service life of the pump body. At the same time, the standard oil mist filter can filter the gas produced by the vacuum pump, purifying the oil and gas discharged by the vacuum pump, not only protecting the working environment and preventing pollution, but also conforming to modern environmental protection concepts, demonstrating the comprehensiveness and forward-looking nature of the product design.

Considering the movement and usage scenarios of the equipment, the DZF series vacuum drying cabinets adopt Foma wheels and casters. These wheels move smoothly, can be adjusted in height, can easily adapt to different road conditions, and have good shock resistance. Whether moving on a flat laboratory floor or using in a complex industrial production environment, it can ensure the smooth operation of the equipment, facilitating users to deploy and adjust the equipment at any time.

In addition, the DZF series vacuum drying cabinets have fully considered the individualized needs of users and provided a wide range of optional functions. Users can select and install RS485 interface/USB interface according to their actual needs, so as to achieve the connection of the equipment with external control systems, data transmission and remote monitoring, and improve the level of automated operation; select and install an independent temperature limiter to further enhance the temperature safety protection function of the equipment; select and install an inert gas valve to meet the need of filling inert gas in some special materials during the drying process to prevent material oxidation; select and install an air intake moisture filter (only for filtering liquid water) to ensure that the gas entering the cabinet is dry and clean, and avoid the adverse effects of moisture on the drying of materials.

The application fields of the DZF series vacuum drying cabinets are extremely wide. In the field of scientific research, it is an excellent assistant for universities and research institutes to conduct various experimental research. Whether it is sample drying in chemical experiments, the preservation of heat-sensitive biological products in biological experiments, or the preparation and drying treatment of new materials in material science research, the DZF series vacuum drying cabinets can play an important role and provide reliable support for the smooth progress of scientific research.

With the continuous growth of market demand and the continuous innovation of technology, the DZF series vacuum drying cabinets are expected to further expand their application fields and improve product performance in the future. For example, in the new energy field, the drying processing requirements for battery materials are getting higher and higher. The DZF series vacuum drying cabinets, with their advanced technology and reliable performance, are expected to play an important role in this emerging field. At the same time, with the continuous development of intelligent technology, future DZF series vacuum drying cabinets may become more intelligent, with functions such as remote monitoring, self-diagnosis of faults, and automatic adjustment of operating parameters, providing users with a more convenient and efficient usage experience.