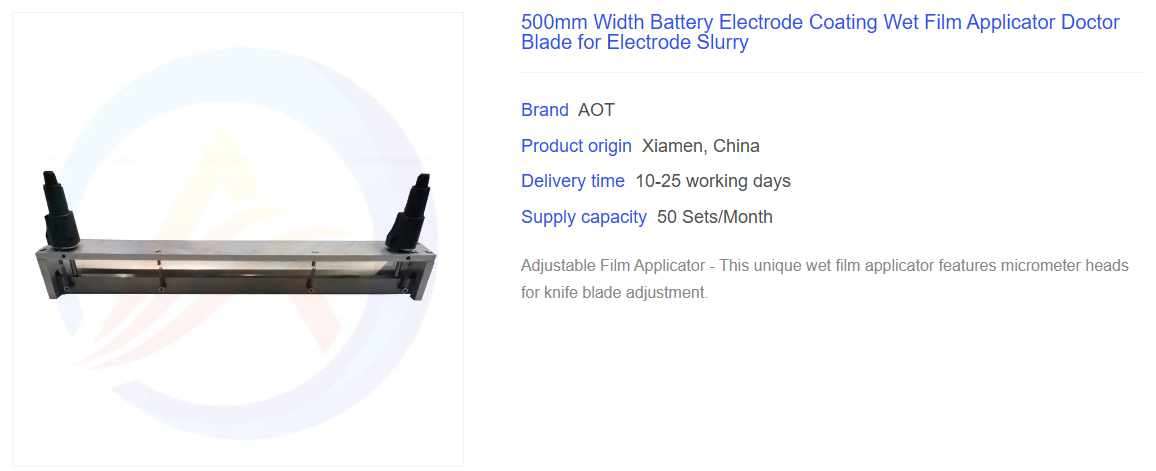

Film Applicator for Battery Electrode Coating

The Film Applicator for Battery Electrode Coating is a specialized piece of equipment designed for the precise and uniform application of coating materials onto battery electrodes. This technology plays a crucial role in the manufacturing process of batteries, particularly in the production of lithium-ion batteries and other advanced energy storage systems.

Film Applicator for Battery Electrode Coating

In the rapidly evolving field of battery technology, the quality and uniformity of electrode coatings directly impact the performance, safety, and longevity of battery cells. To meet these stringent requirements, manufacturers rely on Film Applicators specifically tailored for battery electrode coating applications.

Key Features and Functionalities:

Precision Coating:

The Film Applicator employs advanced coating techniques such as knife coating, rod coating, or slot die coating to ensure precise and consistent deposition of the coating material onto the electrode substrate. This precision is critical for achieving uniform thickness and minimizing defects, which can enhance battery efficiency and capacity.

Adjustable Parameters:

The equipment allows for the adjustment of coating speed, gap settings, and material feed rates to cater to different coating formulations and electrode designs. This versatility ensures that manufacturers can optimize their coating processes for various battery types and applications.

Material Compatibility:

Designed to handle a wide range of coating materials, including slurries, pastes, and dispersions, the Film Applicator ensures compatibility with both traditional and cutting-edge battery chemistries. This adaptability supports the ongoing development of new battery technologies.

Automation and Control:

Many Film Applicators are equipped with automated systems for consistent feeding, coating, and drying of electrodes. Advanced control systems allow for precise monitoring and regulation of coating parameters, ensuring high reproducibility and quality control.

Scalability:

From research and development to large-scale production, Film Applicators are available in various sizes and configurations to meet the needs of different manufacturing scales. This scalability supports the seamless transition from prototype development to commercialization.

Importance in Battery Manufacturing:

The performance of battery electrodes is largely determined by the quality of the coating applied. A Film Applicator ensures that the coating is evenly distributed, defect-free, and meets the exact specifications required for optimal battery performance. This not only enhances the energy density and cycle life of batteries but also contributes to their overall safety and reliability.

Moreover, the ability to precisely control coating parameters enables manufacturers to fine-tune their processes for different battery chemistries and applications, fostering innovation and competitiveness in the battery industry.

Conclusion:

The Film Applicator for Battery Electrode Coating is an indispensable tool in the quest for higher-performance, safer, and more sustainable battery technologies. By providing precise, uniform, and scalable coating solutions, it plays a pivotal role in advancing the capabilities of modern batteries and enabling the transition to a low-carbon future.

The Film Applicator for Battery Electrode Coating is a versatile tool utilized in the production of various types of batteries.

Applicability of Film Applicator for Battery Electrode Coating

The Film Applicator for Battery Electrode Coating is a specialized piece of equipment designed to apply precise and uniform coatings onto battery electrodes. This technology is crucial in the manufacturing process of numerous battery types, enhancing their performance, safety, and longevity. Here are the primary types of batteries that benefit from the use of such a film applicator:

Lithium-Ion Batteries (Li-ion Batteries):

Lithium-ion batteries are widely used in portable electronics, electric vehicles, and energy storage systems. The Film Applicator ensures that the electrode coatings for these batteries are accurately applied, enhancing their energy density, cycle life, and overall performance.

Lithium-Polymer Batteries (Li-poly Batteries):

Lithium-polymer batteries offer higher energy density and flexibility compared to traditional lithium-ion batteries. The Film Applicator is essential in achieving uniform coatings on the flexible substrates used in these batteries, ensuring optimal performance and reliability.

Nickel-Cadmium Batteries (Ni-Cd Batteries):

Although nickel-cadmium batteries are gradually being replaced by more advanced technologies, they still have applications in certain industries due to their robustness and reliability. The Film Applicator can be used to coat the electrodes of Ni-Cd batteries, ensuring consistent performance and extending their lifespan.

Nickel-Metal Hydride Batteries (Ni-MH Batteries):

Nickel-metal hydride batteries are known for their high capacity and good cycling performance. The Film Applicator is instrumental in applying precise coatings to the electrodes of Ni-MH batteries, contributing to their overall efficiency and durability.

Lead-Acid Batteries:

Lead-acid batteries are commonly used in automotive and industrial applications. While they may not require the same level of coating precision as lithium-based batteries, the Film Applicator can still be employed to improve the uniformity and adherence of coatings on lead-acid battery electrodes.

Sodium-Ion and Other Emerging Battery Technologies:

As research and development continue in the field of battery technology, new chemistries such as sodium-ion batteries are emerging. The Film Applicator can be adapted to coat the electrodes of these new battery types, enabling their commercialization and integration into various applications.

The versatility of the Film Applicator for Battery Electrode Coating lies in its ability to handle different coating materials, substrates, and coating processes. This makes it a valuable tool in the manufacturing of a wide range of battery types, from traditional nickel-cadmium and lead-acid batteries to advanced lithium-ion and lithium-polymer batteries.