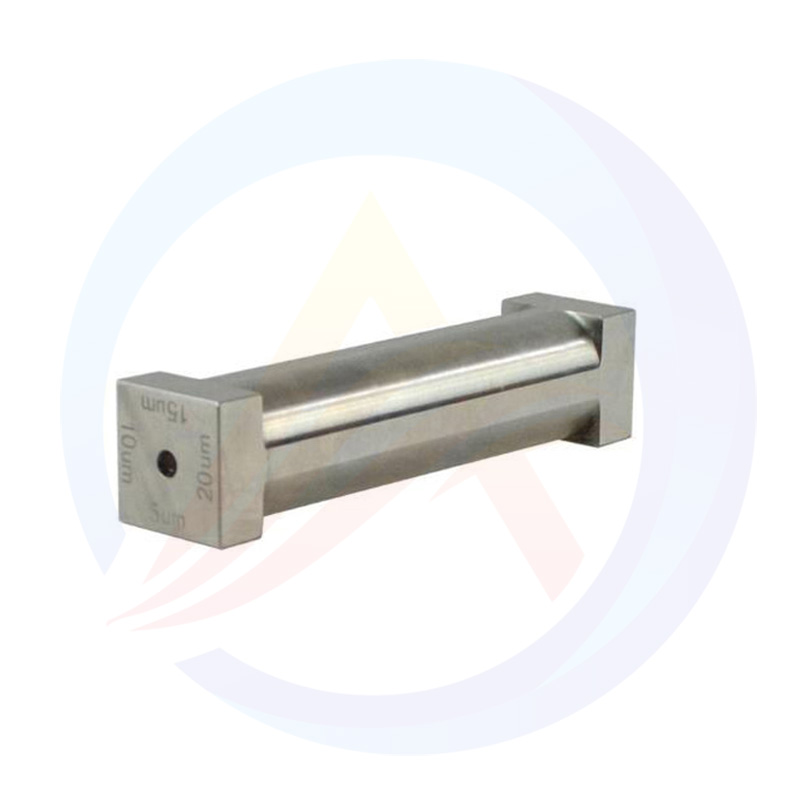

Four Sided Manual Wet Film Applicator

Overview

The Quadruple Film Applicator, also known as the Four-sided Film Coater, is a precision tool designed for uniformly applying a specific thickness of wet film onto flat substrates. It is widely used in various industries for coating applications such as paints, adhesives, and other similar materials.

Key Features

1. High Precision: The applicator ensures a uniform thickness of the wet film, meeting the strict requirements of experiments or production.

2. Four-sided Design: With its four-sided structure, it can easily achieve even coating, avoiding uneven thickness and improving coating quality.

3. Material Saving: By precisely controlling the amount of material applied, the applicator reduces waste and saves material costs.

4. Multi-functional: It is equipped with multiple coating specifications, adapting to different experimental or production needs with high flexibility.

5.Durability: Made of high-quality materials, the applicator is durable and can maintain its coating effect for a long time.

Coating specification

The coating specifications of the four-sided film applicator are diverse, and there are the following types:

1 (5um,10um,15um,20um)

2:(25um,50um,75um,100um)

3:(50um,100um,150um,200um)

4:(30um,60um,90um,120um)

5:(100um, 200um,300um,400um)

6:(50um, 75um,100um,125um)

7:(100um, 150um,200um,250um)

8:(250um, 500um,750um,1000um)

For lithium battery lab research, we usually use No.7 with a thickness of 150um or 250um.

Applications

1. Paint and Coating Industry: The applicator is commonly used for preparing samples, evaluating coating performance (such as hiding power, color, adhesion, etc.), and controlling coating thickness and uniformity in actual production.

2. Adhesive Industry: By precisely controlling the thickness of the adhesive layer, it ensures the effectiveness and performance of the adhesive in bonding processes.

3. Film and Coating Materials: It is also suitable for coating various film and coating materials, such as polymer films, metal films, ceramic coatings, etc.

4. Other Materials: In addition, the applicator can be used for coating other types of materials, such as inks, dyes, lubricants, preservatives, etc.

Usage and Maintenance

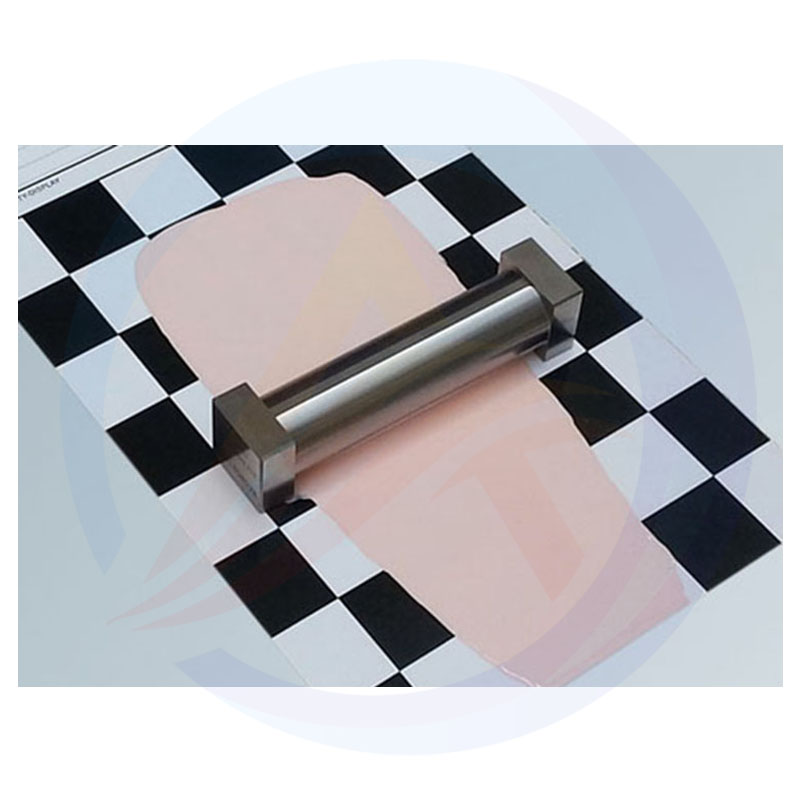

To use the Quadruple Film Applicator, simply fix the substrate on the platform, select the appropriate applicator according to the wet film thickness, pour the sample onto the front of the applicator, and hold it at both ends to slide at a constant speed (e.g., 150mm/s) to apply the desired thickness of wet film. After use, clean the applicator promptly to avoid residue affecting the next use. Store it in a dry, ventilated place to prevent moisture or corrosion when not in use for a long time.

In summary, the Quadruple Film Applicator is a versatile and precise tool with a wide range of applications. Its high precision, four-sided design, material saving, multi-functionality, and durability make it an ideal choice for various coating applications.

Advantages of Quadruple Film Applicator

The Quadruple Film Applicator, also known as the Four-sided Film Coater, boasts an array of advantages that make it a highly favored tool in various coating applications.

1. High Precision and Uniformity:

The applicator ensures a high degree of precision and uniformity in coating thickness, critical for achieving desired product properties and quality standards.

2. Efficiency and Cost-Saving:

By enabling efficient and controlled application of coating materials, it minimizes waste and reduces material costs.

3. Versatility:

Its design accommodates a range of coating specifications, adapting to different experimental or production needs with ease.

4. Durability and Longevity:

Constructed from high-quality materials, the applicator is durable and can withstand frequent use, maintaining its performance over time.

5. Ease of Operation:

Despite its precision, the applicator is relatively easy to operate, allowing even beginners to achieve professional-quality coatings with minimal training

6. Disadvantages of Quadruple Film Applicator

While the Quadruple Film Applicator offers numerous benefits, it also has some limitations to consider:

7. Cost:

High-quality applicators can be relatively expensive, potentially increasing initial investment costs for users.

8. Skill Requirement:

While operation is straightforward, achieving optimal coating results may require a certain level of skill and experience.

9. Maintenance:

Regular cleaning and maintenance are essential to keep the applicator in good working condition, adding to operational overhead.

10. Limited Application Scope:

The applicator is best suited for flat and even surfaces. It may not be as effective on complex or irregularly shaped substrates.

11. Wear and Tear:

Over time, with frequent use, parts of the applicator may wear out, necessitating replacement or repair.

In conclusion, the Quadruple Film Applicator offers a combination of precision, efficiency, and versatility that makes it an invaluable tool for coating applications. However, its cost, maintenance requirements, and limited application scope are factors to consider before investing in this tool.