1.What is a powder press machine in the battery field?

The powder press machine is an indispensable core forming equipment in the research and manufacturing process of new energy batteries. Its core function is to press the dry powder of the positive electrode (such as lithium cobalt oxide, lithium iron phosphate, etc.) or the negative electrode (such as natural graphite, artificial graphite, silicon-carbon composite materials, etc.) into shape-regular, density-uniform, and structure-dense electrode pellets (the prototype of the electrode sheet). From the working principle, it essentially is a precision mechanical device that realizes the displacement, deformation, and close combination of powder particles through a stepped pressure action of "pre-pressing - main pressing - holding pressure", completing the precise reconstruction of the microstructure. Its operational accuracy directly determines the basic performance of the electrode.

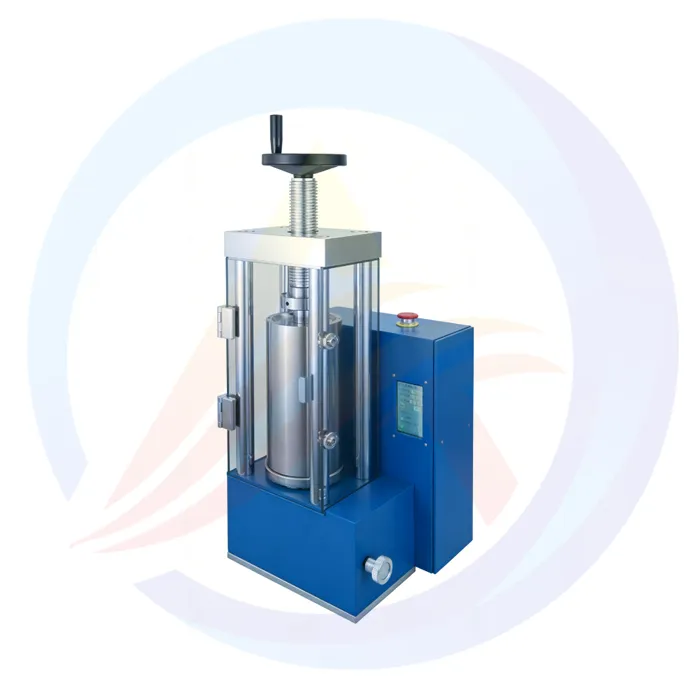

These devices can be clearly classified into two major categories based on application scenarios: laboratory research type and industrial production type. Laboratory research type press machines are mostly small table-like structures, with small size and flexible operation. The core advantage lies in high precision control, mainly used for compressive performance testing of new electrode materials, formula optimization, and small batch sample preparation, and is a key tool for scientific research institutions and enterprise R&D departments to explore new materials and new processes; industrial production type compaction machines are large-scale automated equipment, integrating feeding, pressing, taking, and detection functions, with high production capacity and high stability, capable of meeting the production needs of battery power supplies, energy storage batteries, etc., and are the core components of battery factory production lines. In addition, according to the pressure application method, it can be divided into mechanical compaction machines and hydraulic compaction machines. Among them, hydraulic type is more widely used in high-precision scenarios due to its more stable pressure output and wider adjustment range.

2. Core Function and Effect

Directly optimize the core performance indicators of the battery: The compact density is a key performance parameter of the electrode, and the core function of the powder compaction machine is to precisely control this indicator. By applying pressure reasonably, the internal porosity of the electrode can be reduced, the packing density and contact area of the active material can be increased, thereby bringing about multiple performance improvements: On one hand, it can significantly increase the energy density of the battery. For example, for ternary positive electrode materials, every 0.2g/cm³ increase in compact density can lead to a corresponding increase of 8-10Wh/kg in the energy density of the battery unit, directly contributing to the improvement of battery range; on the other hand, it can reduce the internal resistance of the electrode, optimize the conductivity efficiency of electrons and ions, making the battery charging and discharging faster, with less energy loss, and improving the stability of charging and discharging cycles.

Ensuring the structural integrity and safety of the electrode: Unpressed powder materials are loose and fragile, unable to meet the mechanical strength requirements for battery assembly and use. The powder press machine uses a three-stage forming process. First, it undergoes pre-pressing to remove air and excess gaps in the powder, avoiding defects such as pores and delamination after molding; then, it applies the main pressure to make the particles closely adhere to each other; finally, through the holding pressure process, the pressure is evenly transmitted to all parts of the molded piece, ensuring the electrode structure is dense, the thickness is uniform, and it has sufficient mechanical strength, which can effectively resist stress impacts during battery assembly, charging and discharging cycles, reduce the risk of electrode cracking and powder shedding, thereby extending the battery's cycle life and reducing safety hazards such as short circuits.

Suitable for both R&D and mass production scenarios, supporting the full-cycle development of the industry: In the R&D scenario, the small tablet press can quickly prepare samples with different process parameters, helping R&D personnel efficiently test the compression characteristics, molding effects and electrochemical properties of new materials, significantly shortening the R&D cycle of new materials and new processes. The performance of the samples prepared by it is improved by more than 10% compared to the traditional manual molding method, providing strong support for technological breakthroughs; In the mass production scenario, the fully automatic tablet press, through the linkage with front-end mixing equipment and rear-end electrode cutting equipment, realizes continuous and standardized production of electrodes. It not only ensures the consistency of product quality in large-scale production, but also significantly improves production efficiency and reduces unit production costs, being the core guarantee for the expansion of the battery industry on a large scale.

3. Selection Criteria (Sorted by Priority Based on Core Requirements)

Accurate matching of usage scenarios and production capacity requirements: This is the primary prerequisite for choosing a tablet press. If it is used for laboratory research or small-scale pilot production, a small-sized high-precision tablet press should be selected as the priority. The core parameters to focus on include force measurement accuracy (requiring at least 0.5 grade), displacement resolution (micrometer level, 0.04 μm and below is preferred), pressure adjustment range (suitable for the commonly used 5-50 kN range in laboratories), and it should support multiple loading modes (such as constant pressure, constant displacement, and gradient pressure) as well as automatic recording and traceability of test data, facilitating researchers to compare and analyze the impact of different process parameters; if it is used for industrial mass production, a large-sized automated tablet press should be given priority consideration. The core indicators include production capacity (matching the overall rhythm of the production line), continuous operation stability (the longer the fault-free operation time, the better), mold change efficiency (30 minutes is preferred, reducing production line downtime), and it should also have a linkage interface with other production equipment and support the integration of an automated production line.

Core technical parameters and material characteristics compatibility: The properties of the electrode material (such as hardness, particle size, fluidity, adhesiveness, etc.) directly determine the parameter requirements of the tablet press. It is necessary to ensure that the core parameters of the equipment match the material characteristics. First, the pressure range: The pressure requirements for pressing battery electrodes are typically between 5 and 300 kN. Materials with higher hardness (such as some positive electrode ternary materials) require equipment with a higher pressure limit; second, the holding pressure time: It needs to be within a adjustable range of 0.1 to 0.5 seconds, adjusted according to the material's fluidity to avoid insufficient holding pressure leading to loose structure or excessive holding time affecting production efficiency; in addition, the size accuracy of the pressed piece (thickness tolerance, flatness), and the compatibility of the mold (supporting electrodes of different sizes and shapes) also need to be confirmed according to production or testing requirements to ensure that the target compacted density and product specifications can be precisely achieved.

Safety protection and intelligent control capabilities: During the operation of the tablet press, there are high-pressure mechanical actions involved. Safety protection is an important consideration factor. It is advisable to choose equipment that is equipped with dual safety protection devices, including a rigid steel plate protective frame (to prevent parts from flying off due to equipment failure) and a transparent organic glass observation window (to facilitate real-time observation of the operation status and also provide protection), and it must have safety functions such as automatic pressure relief in case of overpressure and emergency shutdown. When the system pressure exceeds the set threshold or abnormal conditions occur, it can quickly cut off the power source to reduce safety risks.

Meeting the demands of the industry development and long-term compatibility: The technology of new energy batteries evolves rapidly. When choosing a tablet press, one must consider both current needs and future upgrade potential. On one hand, it is necessary to combine the application scenarios at the terminal level (such as the demand for high energy density in battery power supplies, and the requirement for long cycle life in energy storage batteries), select equipment that can be compatible with different powder formulations (such as silicon-carbon negative electrodes, high-nickel ternary positive electrodes and other new materials), and can flexibly adjust process parameters to avoid the situation where the equipment becomes incompatible due to material or process upgrades. On the other hand, it is necessary to refer to the mainstream technical standards and development trends in the industry, select equipment that has upgrade potential in terms of accuracy, stability, and automation level.