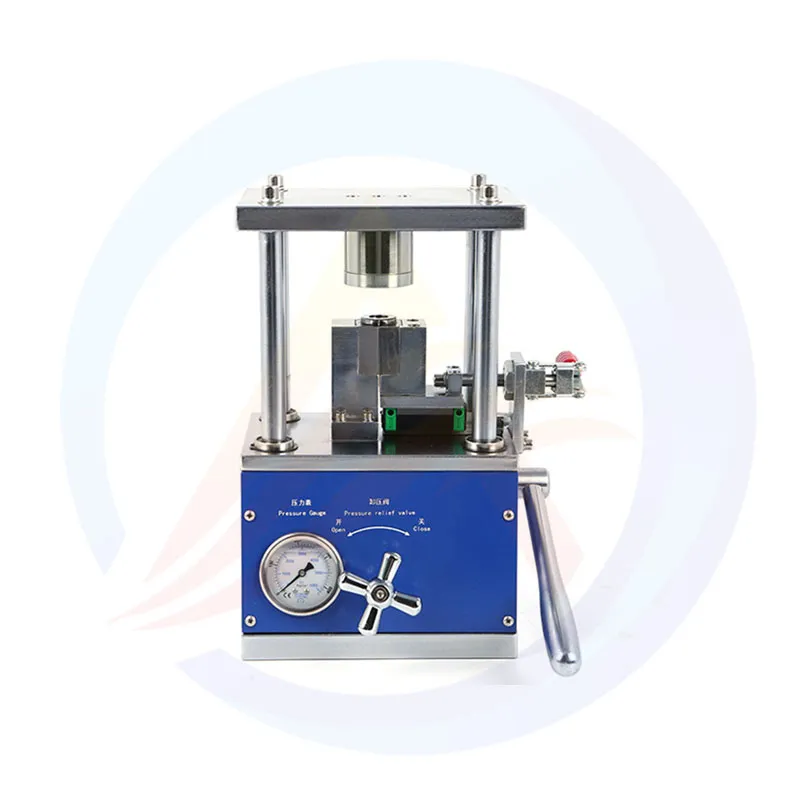

In today's battery manufacturing field, 4680 cylindrical batteries have gradually become the focus of the market due to their advantages such as high energy density and long cycle life. The supporting production equipment, hydraulic sealing machine, plays a crucial role in ensuring the sealing performance, safety, and stability of batteries. Next, we will delve into a hydraulic sealing machine designed specifically for 4680 cylindrical batteries.

Basic Equipment Information

There are many models of this hydraulic sealing machine. Taking AOT-HSM650 as an example, it is mainly used for sealing large-diameter cylindrical batteries such as 4680, 46100, 46120, and 50100. The equipment is driven by hydraulic pressure and powered by hydraulic jacks to ensure stable and reliable sealing process. Its compact structure, small footprint, and ease of layout and installation in various production environments.

Working principle

When the equipment is working, pressure is transmitted to the mold through the hydraulic system. Firstly, place the cylindrical battery to be sealed in a specific mold, activate the hydraulic system, and the hydraulic jack generates strong pressure to push the mold to seal the battery. During the sealing process, pressure is evenly applied to the sealing area of the battery, ensuring a tight fit between the battery casing and the top cover, resulting in a good sealing effect. Taking the 4680 battery as an example, through precise pressure and sealing processes, it can ensure that the electrolyte will not leak during subsequent use, thereby ensuring the performance and safety of the battery.

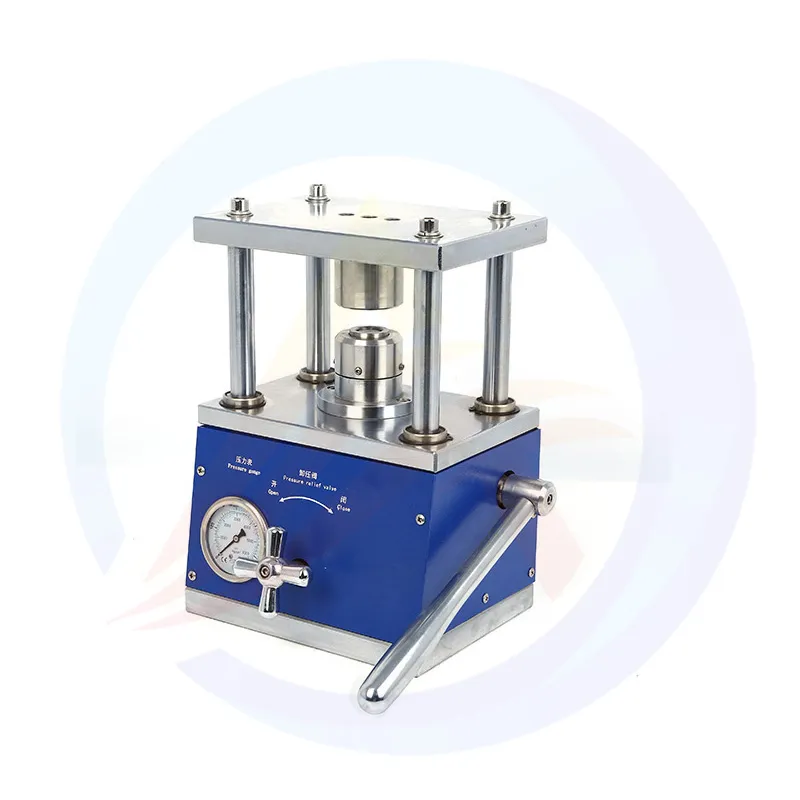

Mold system

hydraulic sealing machine is equipped with a set of standard molds and supports mold customization services, which can meet the diverse needs of different customers for battery sizes. The mold material is made of high-quality materials, such as Japanese imported permanent stainless steel and special oil steel, which have high strength, wear resistance, corrosion resistance and other characteristics, ensuring the service life and sealing quality of the mold. By simply replacing the mold, this device can easily seal cylindrical batteries of different sizes, such as 3560, 4680, 50100, etc. This flexible mold replacement design greatly improves the universality and applicability of equipment, saving equipment procurement costs for enterprises.

Pressure regulation function

Sealing pressure is one of the key factors affecting the sealing quality of batteries. AOT-HSM650 has precise pressure adjustment function, with a pressure range of 80 kg/cm ² -1000 kg/cm ², which can be flexibly adjusted according to the material, size, and sealing requirements of different batteries. The equipment is also equipped with high-precision pressure gauges, allowing operators to intuitively observe pressure values, monitor and adjust sealing pressure in real time, ensuring that each battery can achieve the best sealing effect. At the same time, the equipment is also equipped with pressure limiting settings to avoid sealing problems caused by excessive or insufficient pressure, ensuring consistency and stability of the packaging.

Convenience of operation

In terms of operation, the device is designed to be simple and user-friendly, and the operation process is easy to understand. Even first-time operators can proficiently master the operation methods of equipment in a short period of time after a brief training. The device is compact in size, and some models can be easily placed in a glove box for easy operation in production environments with high environmental requirements. For example, in the battery production process, if it is necessary to avoid contact between the electrolyte and air, the device can be placed in a glove box for battery sealing operation, effectively preventing electrolyte pollution and improving the production quality of batteries. In addition, the maintenance and upkeep of the equipment are also very convenient. Daily simple maintenance such as cleaning and lubricating key components can ensure the normal operation of the equipment

Equipment security

Safety is an important consideration factor for battery production equipment. hydraulic sealing machine has fully considered safety factors in its design and is equipped with comprehensive safety protection devices. For example, the equipment casing is made of high-strength materials, which can effectively prevent operators from accidentally coming into contact with moving parts during equipment operation and avoid injury. At the same time, the equipment is also equipped with an emergency brake button. Once an abnormal situation occurs, the operator can immediately press the button to stop the operation of the equipment, ensuring the safety of personnel and equipment.

Application Fields

hydraulic sealing machine is widely used in various battery production enterprises, including new energy vehicle battery manufacturing, energy storage battery production, and consumer electronics battery manufacturing. In the manufacturing of new energy vehicle batteries, the large-scale application of 4680 cylindrical batteries has made this hydraulic sealing machine an indispensable equipment on the battery production line. Its efficient and stable sealing performance provides strong guarantees for the safe operation of new energy vehicles. In the fields of energy storage batteries and consumer electronics battery production, this device can also meet the strict requirements of different customers for battery sealing quality, helping enterprises produce high-quality battery products.