Innovations in Laboratory Battery Research Equipment: Driving Breakthroughs in New Energy Technology

In today's rapidly evolving new energy technology landscape, laboratory battery research equipment is emerging as a pivotal force driving advancements in battery science. From material development to performance testing, these high-precision instruments not only accelerate the innovation of novel batteries but also provide robust data support for industrial applications.

Technological Breakthrough: Machine Learning Empowers Battery R&D

Recently, machine learning has been deeply integrated into battery research, demonstrating revolutionary potential especially in lithium-ion battery optimization.

According to the latest studies, by combining high-throughput computing with machine learning, scientists can rapidly screen electrode materials and predict their electrochemical properties, reducing traditional experimental cycles by over 50%.

For instance, a Harvard University team utilized algorithm-designed solid-state lithium metal batteries, achieving a lab cycle life exceeding 10,000 times, far surpassing conventional liquid batteries.

Equipment Innovation: Multi-functional Test Systems Lead the Trend

Modern battery laboratories are equipped with comprehensive test systems that integrate multiple functions including charge-discharge, capacity, cycle life, temperature characteristics, and safety testing.

Take a certain model of battery charge-discharge test system as an example: it supports various test modes such as constant current, constant voltage, and pulse, simulating extreme environments from -40℃ to 120℃ with a precision of 0.1%.

The built-in BMS (Battery Management System) test module can simultaneously monitor voltage balancing across multi-cell battery packs, providing critical data for electric vehicle battery pack development.

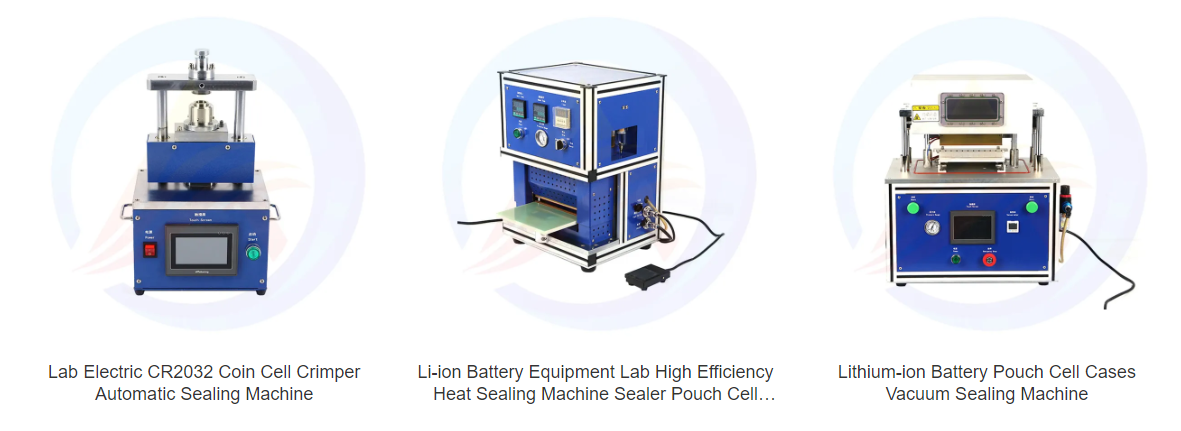

Sealing Technology: Precision Sealing Ensures Experimental Safety

Battery sealing machines, as essential equipment in laboratories, have also undergone remarkable technological advancements. New-generation devices feature modular designs, supporting sealing diameters from 2-50mm and accommodating non-standard samples like coin cells and micro-sensors. A certain brand of sealing machine achieves ±0.5℃ temperature control precision through PID algorithms, preventing thermal damage to sensitive materials such as separators, while integrating vacuum level monitoring to ensure experimental environmental stability.

Scientific Value: End-to-End Support from Lab to Industry

These instruments not only serve basic research but also play a crucial role in industrial transformation. A new energy enterprise utilized high-precision battery testers to successfully increase the yield rate of power batteries from 85% to 98%, saving annual costs exceeding tens of millions of yuan. In solid-state battery R&D, multi-parameter coupled test systems assisted teams in overcoming interfacial impedance challenges, enabling lab samples to reach an energy density of 400Wh/kg, nearing the threshold for commercialization.