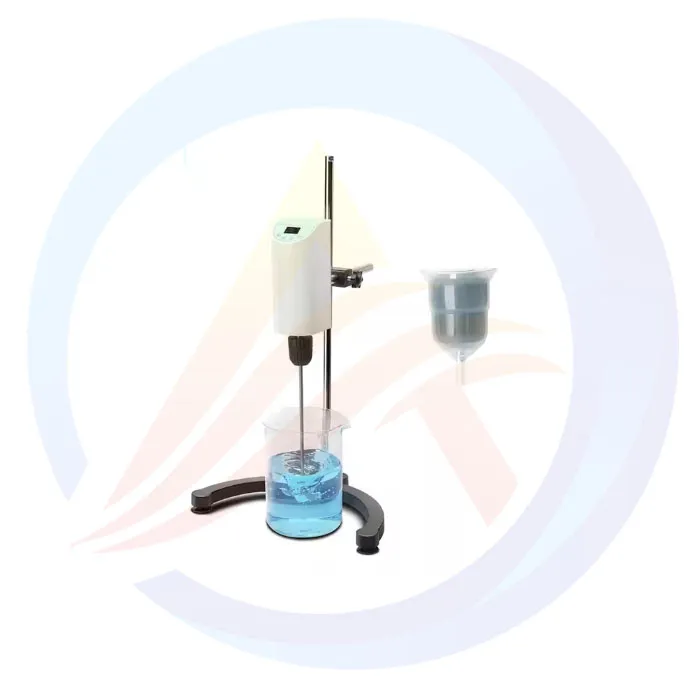

The Laboratory Overhead Stirrer Mixer is a commonly used device in the laboratory. It is driven by a motor to insert the stirrer paddle vertically into the container from the top. The rotational speed (mostly 50-2000rpm) and stirring time can be precisely controlled, and it is suitable for different containers such as beakers and reaction vessels. It is applicable to scenarios such as solution mixing, suspension preparation, and chemical reaction stirring, featuring high stability, excellent stirring efficiency, and easy operation. It is an important tool for scientific research and experiments.

Analysis of Product Core Advantages of the Laboratory Overhead Stirrer Mixer

1. Intelligent control and precise display

OLED display screen: Real time clear display speed (accuracy±1rpm), supports parameter visualization monitoring, and facilitates experimental data recording and adjustment.

Knob speed control design: adjustable in a wide range of 200-2500rpm, with an increase or decrease of 50rpm per gear, meeting different needs from low-speed mixing to high-speed emulsification, and suitable for various experimental scenarios.

2. Safety protection and durability

Overhead Stirrer Mixer Overload automatic shutdown protection: When the mixing load exceeds the motor's bearing range, the system automatically shuts down to avoid motor burnout or mixing blade damage, ensuring experimental safety.

Silicone clamp protective cover: isolates corrosive gases or liquids, prevents clamp from rusting or being corroded, extends equipment service life, especially suitable for experiments in chemical corrosion environments.

IP21 protection level: It can prevent vertically dripping water droplets, suitable for routine laboratory use, and reduces the risk of accidental damage.

3. Efficient mixing and stability performance

Constant speed control technology: Even if the viscosity of the sample changes, the speed can still be maintained stable, avoiding uneven stirring caused by resistance fluctuations and ensuring consistency of experimental results.

Low noise operation: The motor and structure are optimized for low operating noise, suitable for laboratories that are sensitive to environmental noise (such as university research laboratories and pharmaceutical research centers).

Strong power output: With a maximum torque of 20N·cm and a DC brushed motor, it can drive a 10L large capacity mixer, easily handling high viscosity samples such as colloids and suspensions.

Model | AOT-OS10 - Pro |

Max. stirring quantity[H2O] | 10L |

Speed range[RPM] | 200 - 2500 |

Speed display | OLED |

Speed display resolution[RPM] | ±1 |

Speed increase/decrease[RPM] | 50 |

Viscosity max.[mPas] | 10000 |

Motor type | Dc brush motor |

Max. torque | 20N·cm |

Overload protection | Automatic stop |

Chuck clamp range diameter[mm] | 0.5 - 10 |

Protection class | IP21 |

Voltage,Frequency | 100 - 240V,50/60 Hz |

Input power[W] | 45 |

output power[W] | 35 |

power [W] | 50 |

Dimension [W×H×D][mm] | 373×238×623 |

Weight [kg] | 4.8 |

Permissible ambient temperature and humidity | 5 - 40℃,80%RH |

Application Scenarios of the Laboratory Overhead Stirrer Mixer Chemical synthesis: Stir the reactants for a long time in a reaction vessel.

Material preparation: dispersion of nanomaterials, exfoliation of graphene.

Food/cosmetics: homogenization of sauces, lotion and creams.

Pharmaceutical: Control of drug mixing and crystallization processes.

New energy: Mixing of battery slurry (electrode material).