1.What is a Lithium Battery Coating Machine?

Lithium battery coating machines are precision industrial equipment that uniformly applies electrode slurry (active materials, binders, solvents) onto metal foils (copper/aluminum). This critical process determines battery performance metrics like energy density, cycle life, and safety.

(1)Working Principle

Slurry Preparation: Homogenized slurry is fed into the coating head

Coating Application: Blade, roller, or spray mechanisms transfer slurry to moving foil

Thickness Control: Precision gap adjustment (10-200μm) via laser sensors

Drying Phase: Infrared/oven drying at 80-120°C with ±1°C stability

(2)Why Coating Precision Matters

Battery Performance: ±2μm thickness variation reduces capacity by 3% (2023 CELAB Study)

Safety: Uneven coatings cause dendrite growth risks in 67% of thermal runaway cases

2.Three Main Types of Lithium Battery Coating Machines Compared

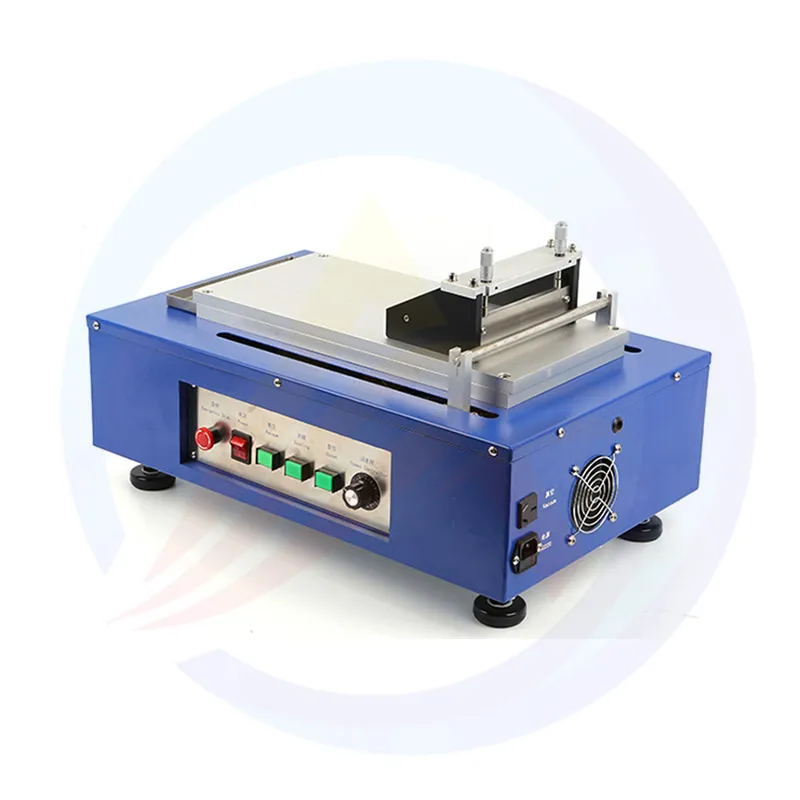

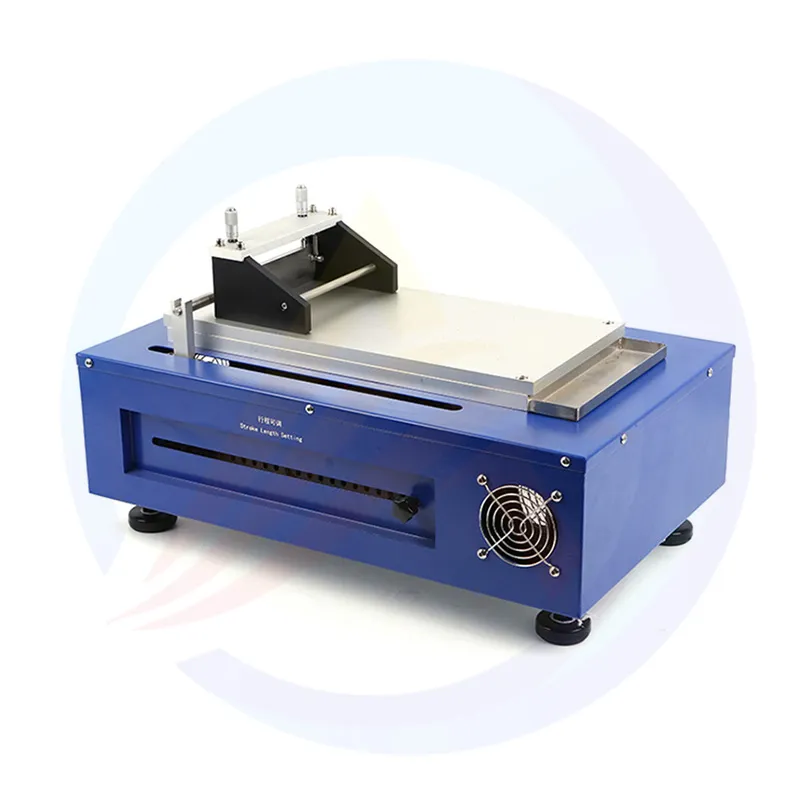

(1)Blade Coating Machines

Mechanism: Fixed blade scrapes excess slurry for ultra-thin coatings (8-15μm)

Best For: High-nickel NMC cathodes requiring 99.5% uniformity

2024 Advance: AI-powered blade pressure adjustment systems

(2)Roll-to-Roll (R2R) Coating Machines

Speed: 25-80 m/min production, 3× faster than blade systems

Innovation: Multi-layer simultaneous coating for solid-state batteries

(3) Spray Coating Machines

Accuracy: 5μm resolution for silicon-anode batteries

Eco-Feature: 92% solvent recovery rate vs. 78% industry average

3.How to Choose the Right Coating Machine: 5 Key Factors

Coating Thickness Range: Match to battery chemistry (e.g., LFP requires 60-120μm)

Line Speed: 30 m/min minimum for EV battery gigafactories

Dryer Efficiency: ≤0.3 kWh/m² energy consumption

Tolerance Control: ≤±1.5μm for premium EV batteries

Upgradeability: Modular designs for future 400Wh/kg batteries

4.Cutting-Edge Technologies Reshaping Coating Machines (Annual Trend Report)

(1)Self-Correcting Coating Heads

Real-time viscosity compensation via IoT sensors

Reduces thickness variation by 40% (Siemens Case Study)

(2) Hydrogen Drying Systems

50% faster drying at 150°C without binder degradation

(3)Digital Twin Optimization

Machine learning predicts coating defects 8hrs in advance (92% accuracy)

5.Industry Applications & ROI Analysis

Case 1: EV Battery Manufacturing

Challenge: Achieve 500 Wh/L density for 800km range EVs

Solution: Dual-sided R2R coating at 45 m/min

Result: 18% capacity increase, $2.1M/year savings

Case 2: Wearable Device Batteries

Requirement: 0.5mm ultrathin cells with curved coating

Technology: 6-axis robotic spray coating

Outcome: 98% yield rate for medical IoT batteries