Introduction

In order to ensure the safe and stable operation of coating process equipment and the consistency of product quality, this article systematically sorts out the standardized operation procedures and maintenance requirements of the core equipment of the coating production line. By clarifying the operating guidelines for key links such as equipment inspection, parameter adjustment, and abnormal handling, the controllability and repeatability of the production process are ensured. This article is applicable to the daily operation of seven core systems such as coating machines, temperature control units, and drying equipment .

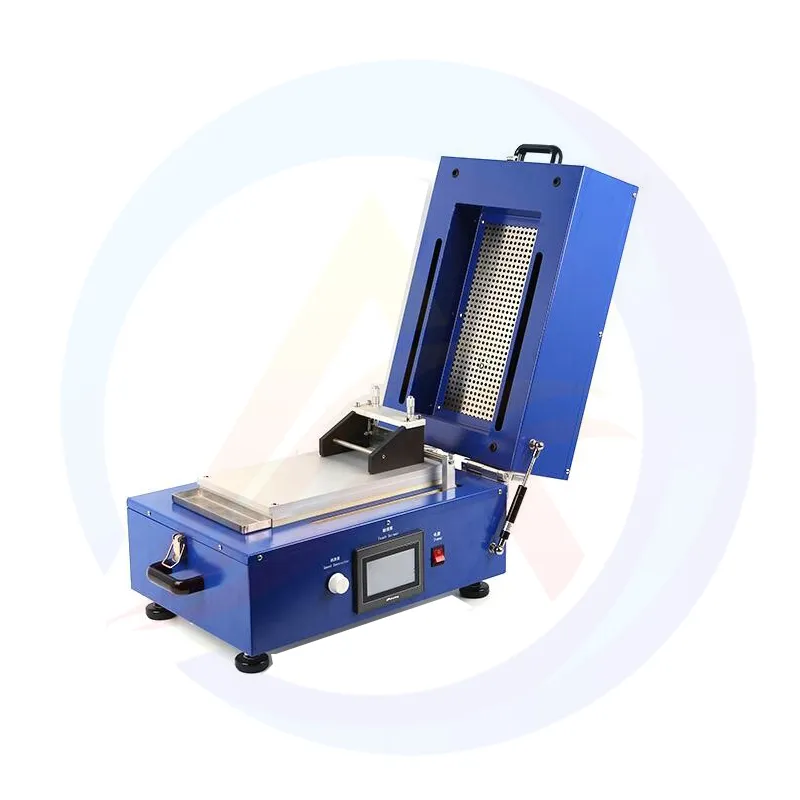

Learn more about the coating process equipment (Introduction to Lithium Battery Coating Process and Main Equipment)

Before starting: Check whether all coating process equipment components are normal and clean the coating roller, scraper, etc.

Parameter adjustment: According to the coating process requirements, adjust the gap between the scraper and the substrate, the pressure and speed of the coating roller and the return roller.

Wear equipment inspection: Check the wear of the scraper regularly and replace it in time to ensure coating accuracy.

Operation monitoring: Observe the coating effect during operation and immediately stop the machine to troubleshoot if any abnormality is found.

Ⅱ. Temperature Control Unit (TCU)

Equipment inspection before starting: Before starting, check whether the thermal oil level, circulation pump, heating system, etc. are operating normally.

Temperature setting: Set appropriate temperature control parameters to avoid coating quality problems caused by too high or too low temperature.

Sealing equipment inspection: Regularly check the sealing performance of TCU to prevent thermal oil leakage.

Component equipment inspection: Check the oven or infrared dryer's heating elements, fans, and ducting for proper operation before starting.

Parameter calibration: accurately set the drying temperature, air speed, time and other parameters according to the slurry properties, coating thickness, etc.

Internal cleaning: Regularly clean the dust and debris inside the equipment to ensure good ventilation and drying efficiency.

Ⅳ. CCD Detection System

Calibration and initialization: Perform equipment calibration and initialization before powering on to ensure detection accuracy.

Software maintenance: Regularly update and maintain the testing software to adapt to new testing requirements.

Operation training: Operators should be familiar with image analysis and judgment standards to ensure the accuracy of test results.

Data management: The test images are stored by batch number, and the storage period is ≥ product warranty period + 1 year

Ⅴ. Slurry mixer

Adding materials: Add raw materials and solvents accurately according to the process formula.

Mixing parameters: Set appropriate mixing speed and time to avoid over-mixing or under-mixing.

Cleaning after mixing: The mixer should be cleaned promptly after mixing to prevent slurry residue from affecting the quality of the next batch.

Ⅵ. Buffer tank

Equipment inspection before use: Before use, check the sealing performance of the buffer tank and whether the stirring device is operating normally.

Cleaning and Disinfection: Clean and disinfect the buffer tank regularly to ensure the purity of the slurry.

Ⅶ. Pump

Installation requirements: When installing the pump, ensure that the inlet and outlet pipes are firmly connected and leak-free.

Flow and pressure regulation: Adjust the pump flow and pressure according to the requirements of the coater.

Component maintenance: Check the pump seals and impellers regularly and replace worn parts in time.

Preventive maintenance: Mechanical seals should be replaced every 2000 hours, bearings should be supplemented with high-temperature grease every 5000 hours , and the machine should be stopped and cleaned immediately when the pressure difference of the inlet filter is greater than 0.1MPa

Conclusion

This specification establishes a complete coating process equipment management system by refining coating process equipment operating parameters, strengthening process monitoring frequency, and clarifying maintenance acceptance standards.

If you need coating process equipment for your coating process engineering, please contact us.(contact us)