In today's rapidly developing field of new energy, lithium batteries as a core component of energy storage, the improvement of its performance and safety is directly related to the progress of electric vehicles, energy storage systems and various portable electronic devices. In the development and production process of lithium batteries, the cleanliness of the environment and the control of moisture and oxygen have extremely high requirements. In this context, the lithium battery glove box plays an indispensable role as a key experimental and production equipment.

1、the definition of lithium battery glove box

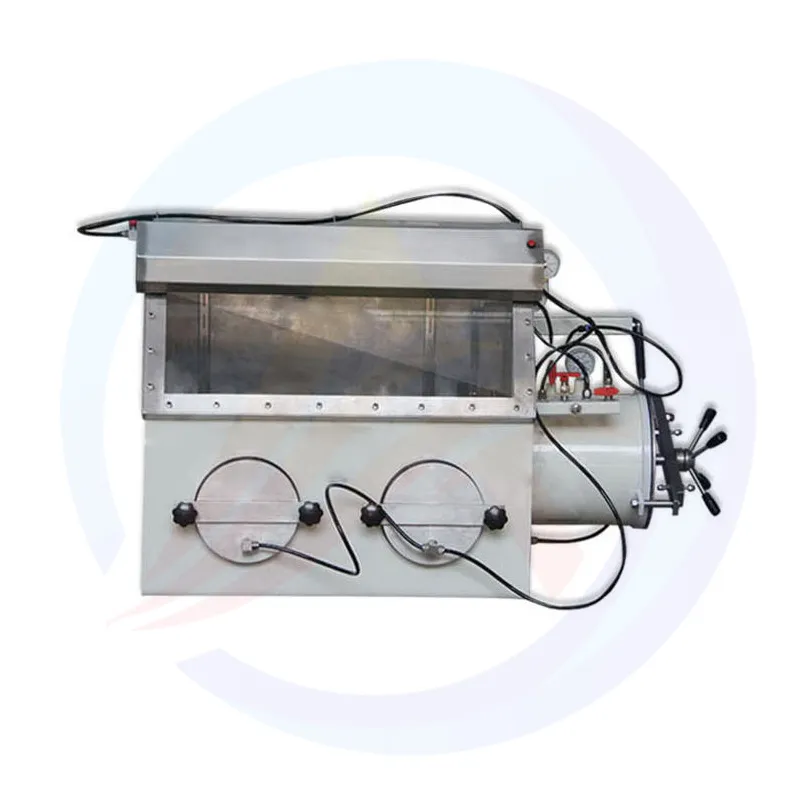

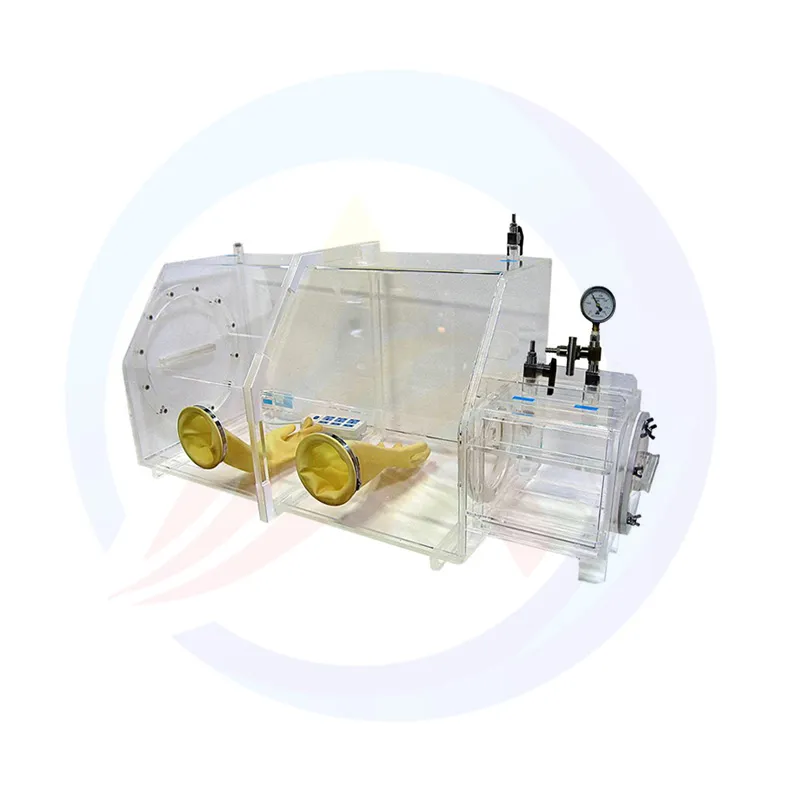

glove box is a kind of high sealing, low oxygen and low water environment operating box designed for lithium battery material research, battery assembly and testing. glove box is made of stainless steel or special alloy materials, and is equipped with an efficient gas purification system, which can reduce the oxygen and water vapor content in the box to very low levels (usually less than 1ppm oxygen content and less than 0.1ppm moisture content). It provides a highly pure, oxygen-free and water-free operating environment for the synthesis of lithium battery materials, the preparation of electrode sheets, the assembly of batteries and the initial performance test.

The design of the glove box allows the operator to operate while maintaining the environmental seal through special gloves or sleeves, which not only ensures the continuity of the experiment or production, but also avoids the intrusion of external pollutants, and is an indispensable auxiliary equipment for the development of lithium batteries and the production line.

2、the working principle of lithium battery glove box

The working principle of the lithium battery glove box is mainly based on the gas cycle purification system. The system consists of several key components:

(1)gas purification unit: glove box usually using molecular sieve, metal hydride and other adsorption materials, effectively remove oxygen and water in the air and other harmful gases, to ensure the high purity of the circulating gas.

(2)gas circulation system:glove box driven by the fan, the gas in the box is continuously circulated through the purification unit to maintain the stability of the environment in the box.

(3)pressure control system:glove box by fine-tuning the intake and exhaust volume, maintain the internal micro positive pressure of the box to prevent the outside air from penetrating through the gap.

(4)monitoring and alarm system: real-time monitoring of the oxygen and moisture content in the box, once it exceeds the preset threshold, immediately issue an alarm and start emergency treatment measures.

In addition, some high-end lithium battery glove boxes are also equipped with temperature and humidity control systems, automatic ventilation functions, and remote monitoring and data recording functions to meet higher levels of experimental and production needs.

3、the importance of lithium battery glove box

(1)improve battery performance: glove box anaerobic anhydrous environment can effectively prevent the battery material in the preparation and storage process oxidation, hydrolysis and other adverse reactions, to ensure the original performance of the battery material, thereby improving the overall performance of the battery.

(2)ensure battery safety: moisture and oxygen are important causes of internal short circuit, thermal runaway and other safety hazards of lithium batteries. Strict control of environmental conditions can significantly reduce safety risks during battery production.

(3)improve production efficiency: the use of lithium battery glove box reduces the repeated experiments and production caused by environmental pollution, improves the success rate of experiments and production, shortens the research and development cycle, and reduces costs.

(4) Promote technological innovation: Provide a stable and controllable experimental environment for researchers, which is conducive to the exploration of new materials and new processes, and promote the continuous innovation of lithium battery technology.

4、lithium battery glove box selection guide

When choosing the right lithium battery glove box, you need to consider the following key factors:

(1)size and capacity: according to the experiment or production scale, choose the appropriate size of the glove box, not only to meet the current needs, but also to reserve a certain space for development.

(2)purification capacity: pay attention to the removal efficiency of oxygen and water, and whether it can effectively remove other harmful gases to ensure the standard of environmental conditions.

(3)the degree of automation: the higher the degree of automation, the easier the operation, but the cost also increases accordingly. Select an appropriate automatic configuration based on actual requirements.

(4)safety performance: including emergency shutdown device, leak detection, pressure control, etc., to ensure rapid response in emergency situations, protect personnel and equipment safety.

(5)after-sales service: Choose a supplier with a good after-sales service system to ensure that the equipment can be timely and effective maintenance and technical support during use.

5、lithium battery glove box in the lithium battery industry

(1)Material research and development: In the synthesis and modification research of key materials such as positive electrode, negative electrode and electrolyte of lithium battery, the glove box provides the necessary anaerobic and water-free environment to ensure the purity and stability of the material.

(2)electrode preparation: the electrode coating, drying, pressing and other processes have high requirements for environmental cleanliness, and the battery glove box can effectively prevent the introduction of dust, moisture and other pollutants.

(3)battery assembly: the assembly process of battery cell winding, lamination, packaging, etc., needs to be carried out in a strictly controlled environment, and the glove box provides an ideal operating platform for this.

(4)performance test: the initial performance test of the battery, such as charge and discharge cycle, internal resistance test, etc., also needs to be carried out in a low-oxygen and low-water environment to ensure the accuracy and reliability of the test results.

In addition, with the continuous development of lithium battery technology, the requirements for glove boxes are also increasing. For example, for the development of new battery systems such as solid-state batteries and lithium-sulfur batteries, higher standards of purification environment and finer temperature and humidity control may be required. Therefore, lithium battery glove box manufacturers need to continue to innovate and improve product performance to meet the needs of industry development.