In the fast-paced realm of battery manufacturing, particularly for lithium batteries, precision and efficiency are paramount. Building upon the previous discussion on lithium battery electrode slitting machines, this article delves deeper into the broader category of slitting machines, shedding light on their significance, technological advancements, and market dynamics.

1.Slitting Machines: An Overview

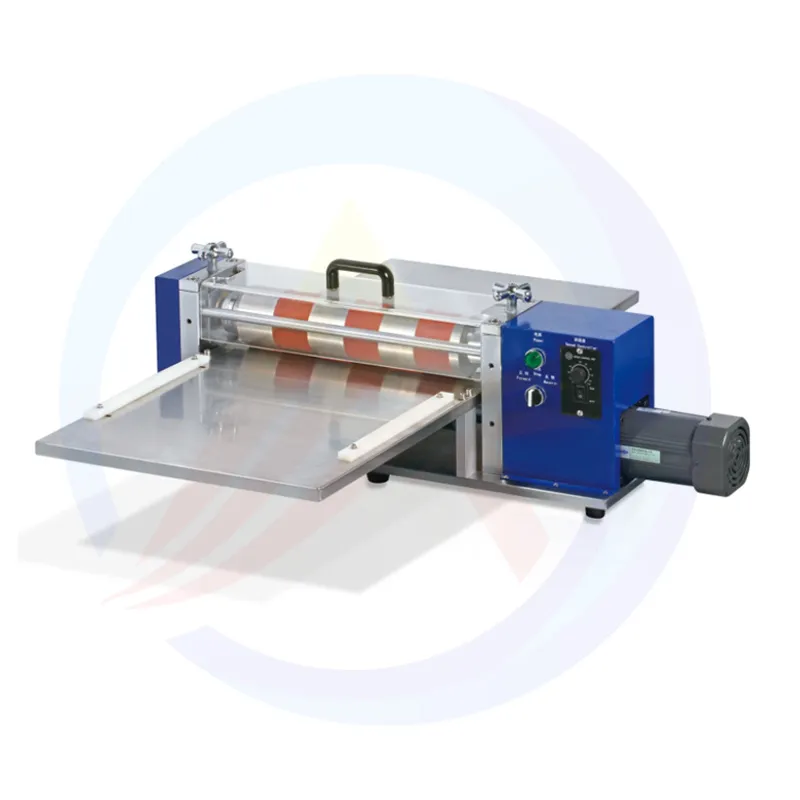

Slitting machines are versatile industrial equipment designed to precisely cut or slit various materials into specific widths and lengths. Beyond lithium battery electrodes, these machines are widely used in industries such as paper, film, metal foils, and textiles. The core principle revolves around utilizing sharp blades or cutting tools to cleanly and accurately divide materials while maintaining their structural integrity.

2.Architectural Design of Slitting Machines

A typical slitting machine comprises several key components. The cutting system, armed with high-precision blades, is the heart of the machine. The unwinding and rewinding units ensure smooth material feed and collection. Advanced tension control systems regulate material tension during the cutting process to prevent deformation or breakage. Additionally, robust mechanical structures and sophisticated control systems work in harmony to guarantee stable and reliable operation.

3.Cutting Techniques Employed

Rotary Shear Cutting : This method utilizes a pair of rotating cylindrical blades. As the material passes between them, it is cleanly cut. Rotary shear cutting offers high-speed capabilities, smooth cut edges, and minimal burrs, making it ideal for processing soft materials like films and papers.

Straight Knife Cutting : Straight knife cutting employs a vertically moving straight blade to slice through materials. It excels in cutting hard or thick materials, such as metal foils and rigid plastic sheets. This method delivers high cutting forces and precise cut lengths.

Circular Saw Cutting : Circular saw cutting relies on a rapidly spinning circular saw blade. It is particularly effective for cutting rigid materials like certain composite materials and hard plastic sheets. This technique provides high cutting efficiency and excellent edge quality.

4.Integration of Advanced Technologies

Automated Control Systems : Modern slitting machines are increasingly equipped with advanced automated control systems. These systems utilize PLCs (Programmable Logic Controllers) and servo motors to precisely control cutting speed, blade position, and material tension. They enable pre-programmed cutting processes, significantly enhancing production efficiency and product consistency.

Precision Instrumentation : To achieve micron-level cutting accuracy, slitting machines incorporate high-precision measuring instruments. Devices such as laser displacement sensors and optical encoders continuously monitor and adjust the cutting process. They ensure that the width and length of the cut material meet stringent precision requirements.

Intelligent Monitoring and Diagnostics : Leveraging sensor technology and data analysis, intelligent monitoring systems provide real-time insights into the operational status of slitting machines. Parameters such as vibration, temperature, and cutting force are monitored. Any anomalies are promptly detected and diagnosed, enabling quick responses to prevent equipment damage and ensure stable production.

5.Market Dynamics and Future Outlook

Growing Market Demand : With the booming electric vehicle market and the widespread adoption of renewable energy storage systems, the demand for lithium batteries continues to soar. Consequently, the market for battery slitting machines is experiencing rapid growth. Additionally, other industries like electronics and packaging are placing higher demands on the precision and efficiency of slitting machines, driving overall market expansion.

Intensifying Market Competition : As the market grows, competition among slitting machine manufacturers is heating up. Renowned domestic and international manufacturers are vying for market share. They are continuously enhancing product performance and quality while reducing costs to gain a competitive edge. Meanwhile, emerging manufacturers are entering the fray, introducing innovative technologies and solutions to disrupt the market landscape.

Green and Sustainable Development : Against the backdrop of increasingly stringent environmental regulations, the slitting machine industry is embracing green and sustainable development. Manufacturers are striving to reduce energy consumption and material waste during production. They are developing more environmentally friendly cutting technologies and equipment to minimize the industry's environmental footprint.

6.Conclusion

Slitting machines play a pivotal role in battery production as well as in numerous other manufacturing sectors. Their continuous evolution and advancement are driven by technological innovations and the demands of various industries. As we look to the future, slitting machines will become more intelligent, automated, and eco-friendly. They will contribute to improving production efficiency, product quality, and driving the sustainable development of the manufacturing industry. For businesses engaged in battery production or related fields, keeping pace with the development trends of slitting machines and adopting advanced slitting technologies are key strategies for enhancing competitiveness and achieving long-term success.