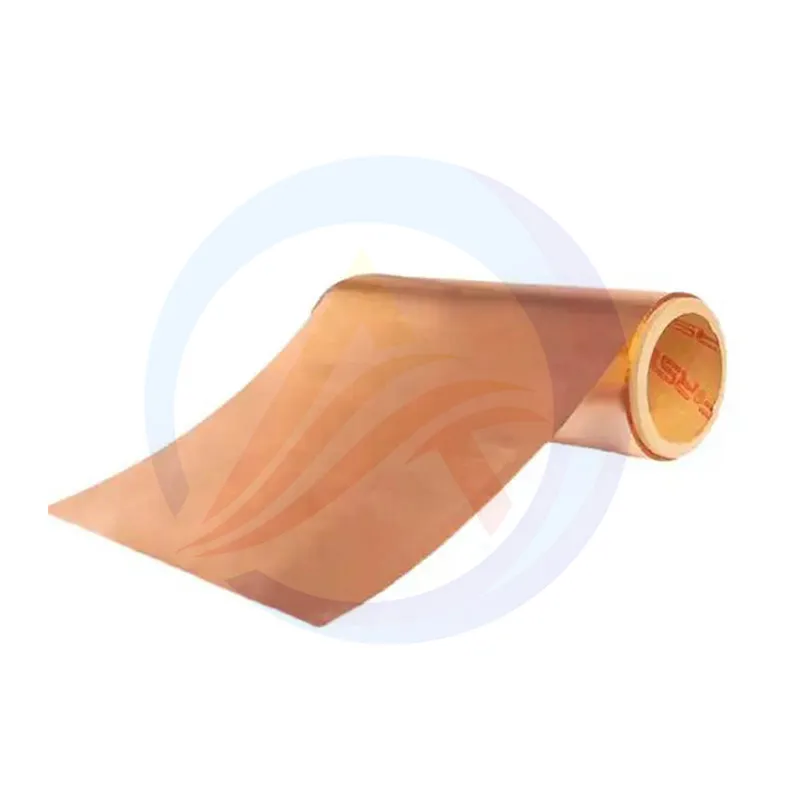

This copper foil is an indispensable component of modern lithium-ion batteries. It serves as the substrate and current conduction pathway for the battery's negative electrode (typically graphite or other active materials). Its quality, performance, and consistency directly impact the battery's energy density, cycle life, safety, and production efficiency.

Key Product Features and Advantages

This copper foil has the following key characteristics:

Extremely high purity

Description: The purity of copper foil is typically required to be above 99.99%.

Advantages: High purity ensures excellent conductivity, reduces the internal resistance of the battery, and minimizes potential side reactions caused by impurities, thereby enhancing the battery's efficiency and safety.

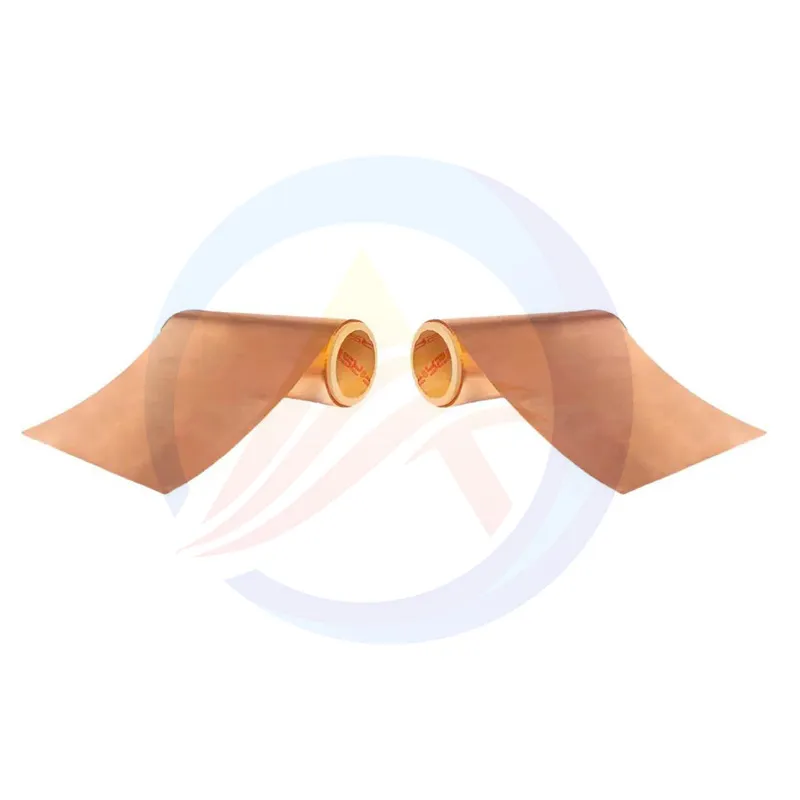

Uniform and consistent thickness

Description: The product thickness typically ranges between 4µm and 12µm, or even thinner, to meet the requirements of high-energy-density batteries. The thickness tolerance is strictly controlled.

Advantages: Uniform thickness is the foundation for ensuring battery consistency, contributing to improved overall performance and yield rates of battery packs. Thinner copper foil can reduce battery weight and increase the space for active materials, thereby enhancing energy density.

Excellent mechanical properties

Description: It exhibits high tensile strength and good elongation (extensibility).

Advantages: The high tensile strength of copper foil prevents breakage during high-speed slitting, tabbing, and winding processes, thereby improving production efficiency. Its excellent ductility ensures better adhesion to active materials and accommodates volume expansion and contraction during battery charge-discharge cycles.

Optimized surface microstructure

Description: This is one of the core technologies of high-end copper foil. By using additives and other methods, the surface of the copper foil can be controlled to form a moderately rough "nodular" or "dendritic" structure (rough side), while the opposite side remains relatively smooth (smooth side).

Advantages: The rough matte surface significantly increases the contact area and mechanical interlocking force with the negative electrode active material, preventing detachment of the coated material and ensuring the battery's long cycle life. The smooth glossy surface helps prevent short circuits with the separator.

Excellent surface tension/wettability

Description: The copper foil surface is treated to ensure good wetting and bonding with the negative electrode slurry (typically a mixture of graphite, solvent, and binder).

Advantages: Ensures uniform coating process, strong adhesion, and prevents powder shedding.

Key Application Areas

This product is specifically designed for the following high-performance lithium-ion batteries:

Power battery: Used in electric vehicles, electric bicycles, drones, and the like.

Energy storage battery: Used for grid energy storage, home energy storage, communication base stations, etc.

Consumer electronics batteries: Used in smartphones, laptops, tablets, wearable devices, and more.

High-rate battery: A battery with specific requirements for charging and discharging currents, such as electric tools and model aircraft.