In the current era of rapid development in the new energy industry, lithium batteries have become the core energy carriers in fields such as electric vehicles, energy storage devices, and consumer electronics. In the production process of lithium batteries, the stacking procedure directly determines the performance and quality of the battery cells. The lithium battery stacking machine, which undertakes this task, has thus become an indispensable key equipment in the industrial chain. Please provide the text you would like translated.

1、What is a lithium battery stacking machine?

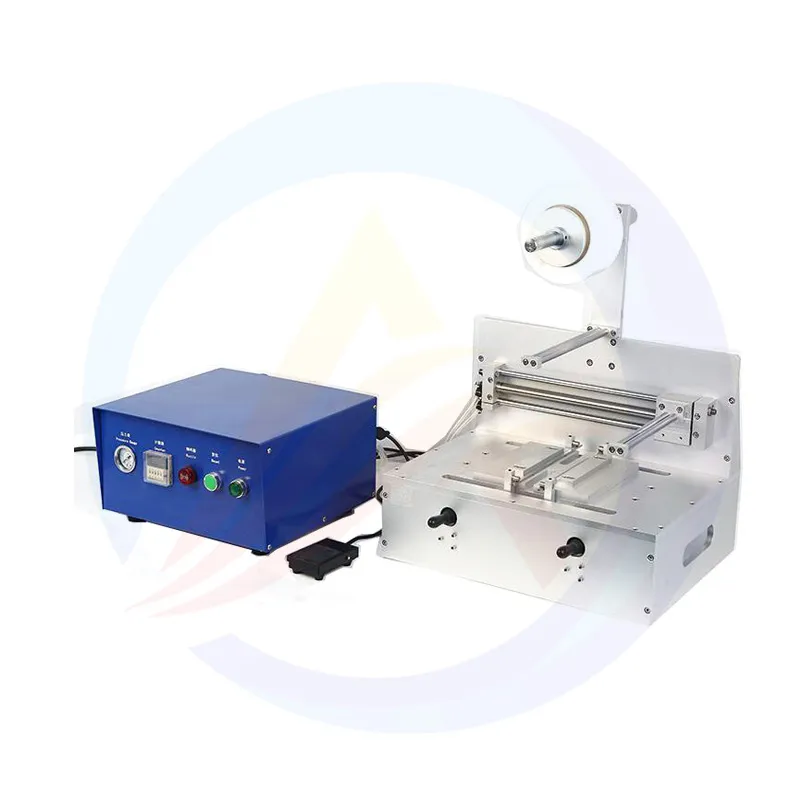

In simple terms, a lithium battery stacking machine is an automated device specifically designed to "build the core" of lithium batteries. The core component of a lithium battery, the "cell", is composed of positive electrode sheets, negative electrode sheets, and separators stacked in a specific order. The core task of the stacking machine is to precisely stack the pre-cut positive and negative electrode sheets and separators in the sequence of "positive electrode - separator - negative electrode - separator", ultimately forming the cell body capable of storing electrical energy. Please provide the text you would like translated.

Although it is similar to the principle of daily "paper folding", the precision requirements are vastly different. A few millimeters of deviation in paper folding is not a big deal, but when a laminating machine folds electrode sheets, even a deviation of just 0.01 millimeters can cause battery short circuits, bulging, and even safety hazards. Moreover, the laminating machine relies on mechanical structures, visual recognition, and automatic control systems to achieve high-speed and continuous laminating operations, with an extremely high degree of automation, which is the core guarantee for the large-scale production of lithium batteries. Please provide the text you would like translated.

2、The Three Core Functions of the Stacker

(1) Ensuring the Basic Performance of the Battery Cells

The energy density (storage capacity) and cycle life (service life) of lithium batteries are closely related to the quality of the stacking of the electrode sheets and separators. By precisely aligning the electrode sheets and separators, the stacker can maximize the internal space of the battery cells, prevent space waste due to misalignment during stacking, and avoid direct contact between the positive and negative electrodes caused by improper placement of the separators. Please provide the text you would like translated.

(2) Enhance Efficiency and Reduce Costs

Before the widespread adoption of stacking machines, some small manufacturers relied on manual stacking of electrode plates. A worker could stack at most 10 to 20 small battery cells per hour, with a low pass rate. Nowadays, an ordinary stacking machine can complete the stacking of 150 to 200 power battery cells per hour, with a pass rate consistently above 99.5%. While efficiency has increased, it has not only reduced labor costs but also decreased material waste caused by human errors. This directly contributes to the decline in lithium battery production costs, providing support for the affordability of products such as electric vehicles and power banks. Please provide the text you would like translated.

(3) Adapt to Diverse Production Demands

Lithium batteries come in various types, including prismatic (such as BYD's Blade Battery), pouch (such as some mobile phone batteries), and new large cylindrical (such as Tesla's 4680 Battery). The electrode sheet sizes and stacking sequences of different types of lithium batteries vary significantly. Stacking machines can adapt to different production demands by adjusting feeding speed, stacking pressure, positioning parameters, etc. For instance, when producing pouch batteries, the suction force of the suction cups is reduced to prevent electrode sheet damage; when manufacturing large cylindrical batteries, a "winding + stacking combination" mode is adopted to meet process requirements. Without such adaptability, enterprises would need to frequently replace equipment when producing different types of batteries, which would significantly increase costs. Please provide the text you would like translated.

3、How to Choose the Right Stacker?

(1) Accuracy is the top priority, which is the foundation of cell safety.

Alignment accuracy of electrode sheets: When the positive electrode sheet, negative electrode sheet, and separator are stacked together, the deviation should not be too large. For ordinary power batteries (such as the common square cells in electric vehicles), an alignment deviation within ±0.02 mm is sufficient to meet the requirements. This level of accuracy can prevent direct contact between the positive and negative electrodes, which could cause a short circuit. However, for high-end cells like the Qilin battery or solid-state batteries, higher precision is required. You should choose equipment that can keep the deviation within ±0.01 mm. This is because these cells have high energy density, and even a slight misalignment of the electrode sheets can lead to issues such as bulging, overheating during charging, and even safety accidents. Please provide the text you would like translated.

Consistency of stacking thickness: The stacked cells must not be "thick on one side and thin on the other". For example, when stacking 10 layers of electrode sheets and separators, the overall thickness deviation should be controlled within 0.05 millimeters. If the thickness is uneven, the current distribution inside the cell will be unbalanced, and the local temperature will soar during charging, which not only affects the battery life but also may pose safety hazards. Please provide the text you would like translated.

(2) Next, let's look at "speed". It should be matched with the production line's rhythm. The speed of a stacking machine is not "the faster, the better".

Blindly pursuing high speed can actually waste money. The key is to be compatible with the efficiency of upstream and downstream equipment. Understanding speed parameters: The speed of a stacking machine is usually expressed as "how many cells are stacked per hour (PPH)". The speed of ordinary models on the market is 150-200 PPH, while high-speed models can reach 200-250 PPH. However, faster equipment is also more expensive, generally 20%-30% more expensive than ordinary models. If high speed is not needed, this money is wasted. Please provide the text you would like translated.

Matching production lines: Before making a selection, calculate clearly the "bottleneck speed" of your own production line. For instance, if your electrode sheet cutting machine can cut a maximum of 180 electrode sheets per hour, even if you purchase a high-speed laminating machine with a capacity of 200 PPH, it can only operate at the pace of the cutting machine, laminating a maximum of 180 sheets per hour. The remaining 20 PPH of capacity would be wasted, and it would also lead to a buildup of laminated cells before subsequent processes, increasing storage and handling costs. Conversely, if the laminating machine is too slow, for example, if the cutting machine can cut 200 sheets per hour but the laminating machine can only laminate 150, the cutting machine would be left "waiting for work", which would also affect overall efficiency. Please provide the text you would like translated.