1、lithium battery electrode manual die cutting machine working principle

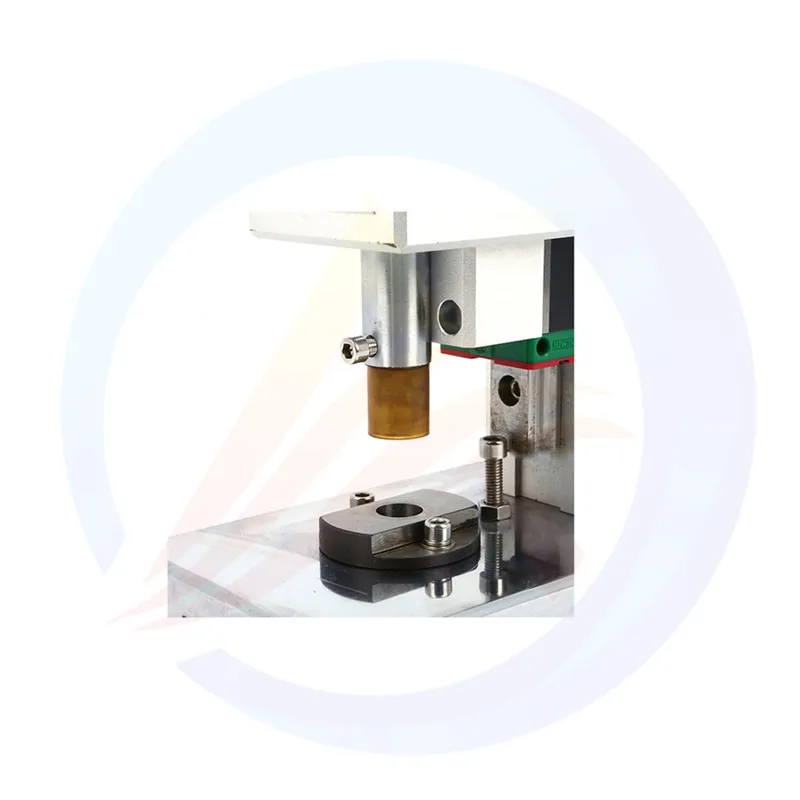

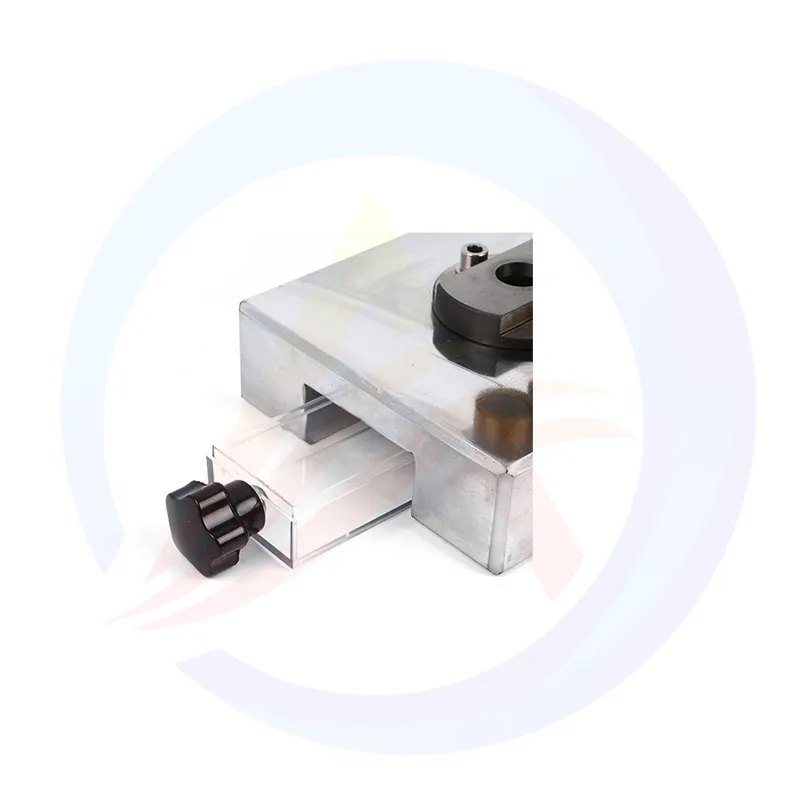

(1) Basic structure

Lithium battery electrode manual die cutting machine is usually composed of die cutting knife, knife holder, workbench, pressure adjustment device, positioning system and other parts. The die cutter is the core component, and its shape and sharpness directly determine the precision and effect of cutting. The tool holder is used to hold the die cutter and ensure its stability during the cutting process. The table provides a surface for electrode placement and operation, and generally has good flatness and wear resistance. The pressure regulating device can adjust the pressure of the die cutter on the electrode according to the different characteristics and cutting requirements of the electrode material to achieve the best cutting effect. The positioning system is responsible for accurately determining the cutting position of the electrode and ensuring that the size of the electrode after cutting meets the design standard.

(2) Cutting process

At work, the operator first places the lithium battery electrode to be cut on the work table and fixes it precisely at the predetermined cutting position through the positioning system. Then, according to the thickness and hardness of the electrode material and other parameters, adjust the pressure adjustment device, set the appropriate die-cutting pressure. Then, the die cutting machine is started, and the die cutting knife cuts the electrode under pressure. Because the shape of the die cutter matches the shape of the required electrode, the electrode can be cut into a variety of complex shapes, such as round, square, rectangular, etc., and can ensure the uniformity and smoothness of the cutting edge.

2、lithium battery electrode manual die-cutting machine

(1) Precise size control

In the production of lithium batteries, different models and specifications of batteries have strict requirements for the size of the electrodes. The lithium battery electrode manual die-cutting machine can precisely cut the electrode material to the required size, and the error can be controlled within a very small range.

(2) Shape customization

Lithium batteries have a variety of application scenarios, which requires the electrodes to have different shapes. The manual die cutter can cut the electrode into a variety of customized shapes according to the customer's needs and battery design. Whether round, square or special-shaped electrodes with special profiles, they can be easily achieved by manual die-cutting machines. This ability to customize the shape allows the lithium battery to better adapt to the internal space layout of different devices, improving the versatility and adaptability of the lithium battery.

(3) Adapt to different material characteristics

There are many kinds of lithium battery electrode materials, including various metal oxides, phosphates, carbon materials, etc., and their physical and chemical properties differ greatly, such as hardness, toughness, viscosity, and so on. The lithium battery electrode manual die-cutting machine can flexibly adjust cutting parameters, such as pressure and cutting speed, according to the characteristics of different electrode materials.

(4) Cost control and flexibility

Compared with automatic large-scale die-cutting equipment, lithium battery electrode manual die-cutting machine has lower equipment procurement costs and maintenance costs. For some small lithium battery manufacturers or research and development institutions, manual die-cutting machines are an affordable choice. At the same time, the manual die-cutting machine has high flexibility in the production process. When it is necessary to carry out small batch production, sample production or product development, the manual die-cutting machine can quickly adjust the cutting parameters and molds to adapt to different production tasks, without complex programming and debugging like automation equipment, which greatly reduces the production preparation time and improves production efficiency.

(5) Quality inspection and optimization

In the manual die cutting process, the operator can observe the cutting situation of the electrode more intuitively, and timely find the problems in the cutting process, such as material layering, edge burrs, etc. This facilitates real-time detection and control of electrode quality during the production process. If a quality problem is found, the parameters of the die cutter can be adjusted immediately or the state of the die can be checked to optimize the cutting process, thereby improving the overall quality of the electrode.

3、lithium battery electrode manual die-cutting machine technical characteristics

(1) High-precision positioning system

In order to achieve accurate electrode cutting, the lithium battery electrode manual die-cutting machine is equipped with a high-precision positioning system. Common positioning methods include mechanical positioning, optical positioning and laser positioning. Mechanical positioning Through precision guide rail, slide and positioning pin and other components, to achieve the accurate fixing and positioning of the electrode, with simple structure, high reliability. Optical positioning uses camera and image processing technology to accurately identify and position the position and shape of the electrode, which can achieve higher positioning accuracy, and is suitable for production tasks that require extremely strict electrode size and shape. Laser positioning is the use of laser high directivity and high energy density characteristics, the formation of accurate marks or fixing points on the surface of the electrode, with the advantages of fast positioning speed, high precision and non-contact, will not cause damage to the electrode material.

(2) high-quality die cutting tools

The quality of die cutting tool directly affects the cutting effect and electrode quality. Lithium battery electrode manual die-cutting machine usually uses high strength, high hardness and good wear resistance tool materials, such as carbide, high-speed steel and so on. These tool materials maintain a sharp edge during a long cutting process, reducing tool wear and replacement frequency. At the same time, the manufacturing process of the tool is also very critical, the use of precision processing technology, such as electric discharge machining, wire cutting processing, etc., to ensure the shape accuracy and dimensional accuracy of the tool to achieve high-precision electrode cutting. In addition, in order to adapt to different electrode materials and cutting requirements, die cutting tools can also be designed into different shapes and structures, such as flat knives, round knives, special-shaped knives, etc., and can be surface coating treatment, such as titanium nitride coating, to improve the hardness, wear resistance and lubrication of the tool.

(3) Pressure regulation and control technology

Precise pressure regulation is one of the important technical features of manual die-cutting machine for lithium battery electrode. The pressure regulating device can achieve precise pressure adjustment in a wide range according to the characteristics of the electrode material and the cutting requirements. Generally, pneumatic or hydraulic pressure regulation system is used to control the pressure of the die cutter on the electrode by adjusting the pressure of the gas or liquid. The pressure regulating system is usually equipped with pressure sensors and pressure gauges, which can monitor and display the pressure value in real time, and the operator can accurately set and adjust the pressure according to the actual situation.

4、lithium battery electrode manual die-cutting machine in the lithium battery industry application status and development trend

(1) Application status

At present, lithium battery electrode manual die-cutting machine has been widely used in the lithium battery industry. In small lithium battery production enterprises, manual die-cutting machine is the main electrode cutting equipment for the production of lithium batteries in consumer electronic products, such as mobile phone batteries, tablet computer batteries, etc. In large lithium battery production enterprises, although the automatic die-cutting equipment occupies a dominant position, the manual die-cutting machine is still used as an auxiliary equipment for small batch production, sample production, process research and development and equipment debugging.

(2) Development trend

With the continuous development of the lithium battery industry and the progress of technology, the lithium battery electrode manual die-cutting machine is also constantly evolving and developing. First of all, in terms of accuracy, the future manual die-cutting machine will further improve the positioning accuracy and cutting accuracy to meet the increasing requirements of lithium batteries for electrode size and shape accuracy. Secondly, in terms of intelligence, the manual die-cutting machine will gradually integrate more intelligent control technology, such as automatic parameter adjustment, fault diagnosis and early warning functions, and improve the operation convenience and production efficiency of the equipment.

5、Conclusion

As a key equipment in the manufacturing process of lithium battery electrode, manual die-cutting machine plays an extremely important role in electrode size control, shape customization, material adaptability, cost control and quality inspection. It has the technical characteristics of high-precision positioning system, high-quality die-cutting tools, accurate pressure regulation technology and perfect safety protection design, and has a wide range of applications in the current lithium battery industry.