1, the basic overview of lithium battery slitting machine

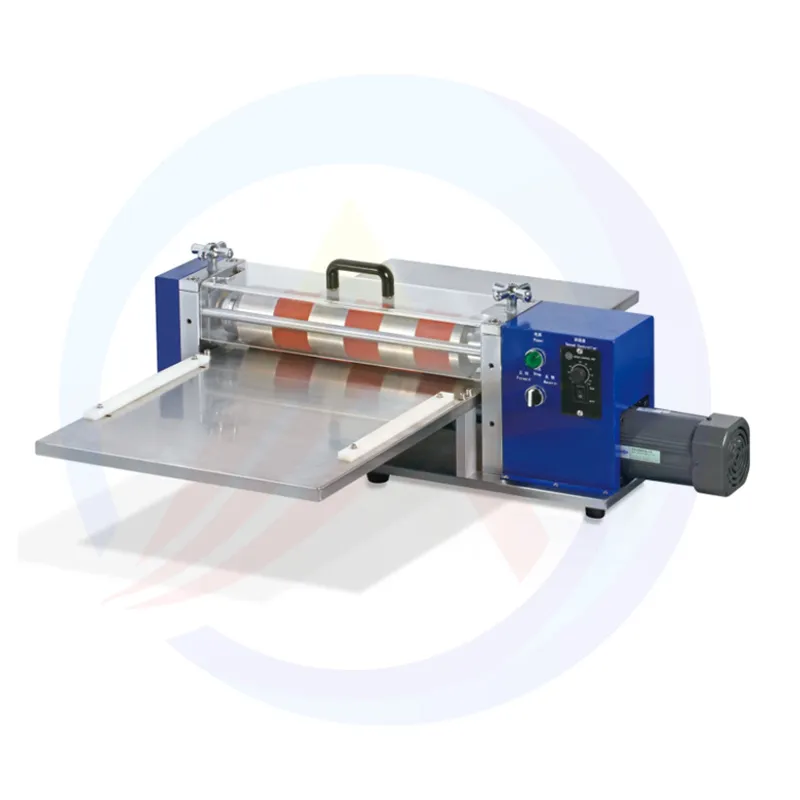

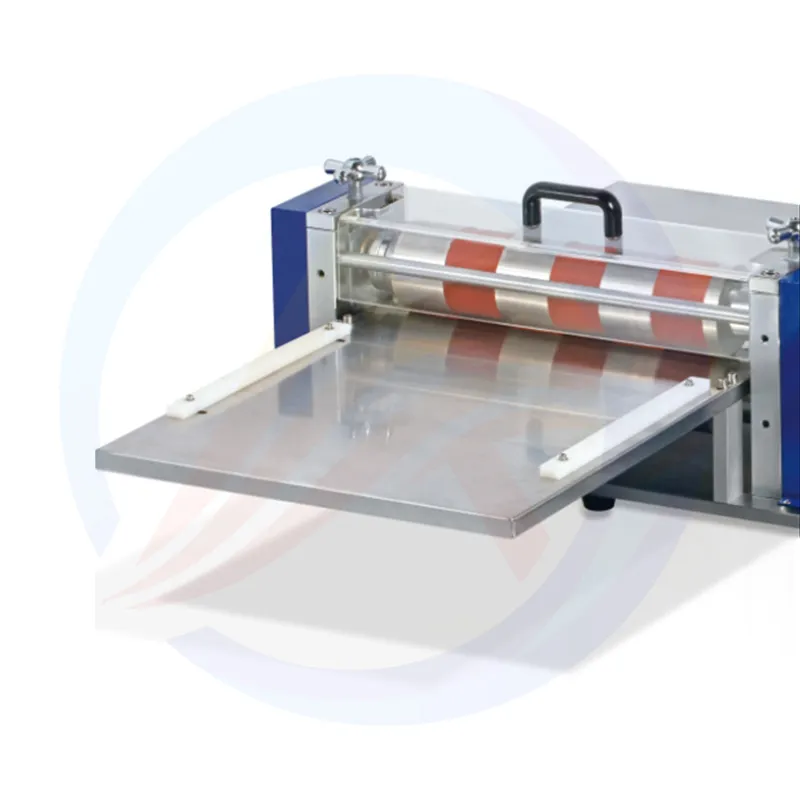

Lithium battery slitting machine is a specialized equipment for cutting materials such as electrode sheets and diaphragms in the production process of lithium batteries. It is mainly composed of core components such as winding mechanism, cutting mechanism, winding mechanism and control system. The working process is usually to first place the rolled electrode sheet or diaphragm material on the unwinding mechanism, and then cut it according to the predetermined size and shape by the precisely controlled cutting mechanism, and finally the cut material is rewound by the winding mechanism for subsequent production processes.

In the manufacturing process chain of lithium batteries, the slitting machine is in the middle stream position, undertaking the preliminary processing of upstream raw materials and downstream cell assembly and other key links. Its processing accuracy, cutting efficiency and stability directly affect the overall quality and production efficiency of lithium batteries.

2, lithium battery slitting machine in the precise control of electrode size

(1) Meet diverse design needs

Lithium batteries have a wide range of application scenarios, from tiny wearable devices to large-scale energy storage power stations, and different applications have very different requirements for the size and shape of lithium batteries. The lithium battery slitting machine can accurately cut the electrode sheet into a variety of specific sizes, whether rectangular, square or shaped, which can be achieved by adjusting the parameters of the slitting machine.

(2) Ensure the consistency of the battery cell

In the process of cell assembly of lithium battery, the consistency of electrode sheet is very important for the stability and reliability of cell performance. If there is a large deviation in the size of the electrode sheet, it will lead to an uneven internal structure of the cell, affecting the transmission and distribution of lithium ions, and thereby reducing the charge and discharge efficiency, cycle life and safety of the battery. With its advanced positioning and cutting technology, the lithium battery slitting machine can ensure that the electrode size of the same batch or even different batches is highly consistent.

3, lithium battery slitting machine to optimize the quality of electrode edge

(1) Reduce burrs and defects

The edge quality of the electrode is directly related to the safety and performance of the lithium battery. During the cutting process, if there are burrs or other edge defects, the electrode may be short-circuiting during the winding or laminating process, resulting in serious safety problems such as thermal runaway of the battery. Through the use of advanced cutting technology and tool materials, the lithium battery slitting machine can effectively reduce the burrs and defects on the edge of the electrode.

(2) Improve battery performance stability

Good electrode edge quality not only ensures safety, but also has a positive impact on the performance stability of the battery. The smooth and flat edge helps to reduce the uneven local current density in the charging and discharging process of the electrode sheet, so that the embedding and deembedding process of lithium ions in the electrode sheet is more uniform and orderly, thus improving the charging and discharging efficiency and cycle life of the battery. In addition, high-quality edge quality can also reduce the contact resistance between the electrode sheet and the diaphragm, improve the internal resistance characteristics of the battery, and further enhance the overall performance of the battery. The efforts of the lithium battery slitting machine in optimizing the edge quality of the electrode sheet have laid the foundation for the stable performance of the lithium battery under various complex conditions.

4, the role of lithium battery slitting machine in diaphragm cutting and processing

(1) Precise cutting diaphragm

The diaphragm is a key component of the lithium battery, which plays an important role in isolating the positive and negative electrodes and preventing short circuit. The lithium battery slitting machine can precisely cut the rolled diaphragm material into the required width and length to adapt to the production needs of different specifications of lithium batteries. During the cutting process, the scutter needs to ensure that the incision of the diaphragm is neat and undamaged, and the dimensional accuracy meets the requirements.

(2) Special treatment to improve diaphragm performance

In addition to the conventional cutting function, some advanced lithium battery slitters also have the ability to perform special treatment on the diaphragm to further improve the performance of the diaphragm. For example, by surface coating treatment, the wettability of the diaphragm can be improved, so that the electrolyte can better infiltrate the diaphragm and improve the efficiency of ion conduction. Or punch holes on the diaphragm to increase the passage rate of lithium ions and reduce the internal resistance of the battery.

5,Conclusion

Lithium battery slitting machine plays an extremely important role in the lithium battery manufacturing process. Its excellent performance in precise electrode size control, edge quality optimization, diaphragm cutting and processing, etc., provides a strong guarantee for high performance, high safety and customized production of lithium batteries.