The AOT-MSK-500B cylindrical battery grooving machine is a device that can be applied to the grooving process of cylindrical batteries and supercapacitors,

The equipment comes standard with a set of 18650 groove rolling molds (specific dimensions can be customized). By replacing the groove rolling molds, cylindrical batteries and supercapacitors with outer diameters ranging from 10mm to 50mm and lengths from L20mm to L140mm can be processed for groove rolling.

Functional Features:

1. Adjustable groove size, high precision, and stable groove size;

2. PLC touch screen parameter setting;

3. Changing the mold allows for groove machining of cylindrical battery cases and supercapacitors of various specifications;

4. It can be used inside the glove box through a transition chamber with an inner diameter greater than 360mm

Technical Parameter:

Product Name | Cylindrical Battery Grooving Machine |

Power Supply | Single-phase AC220V ± 10%, frequency 50Hz, power 0.3KW |

Gas Source | 0.5-0.8MPa compressed air or high-pressure gas cylinder (high-pressure gas cylinders should be used after reducing pressure to 1.3-1.5MPa) |

Note | 1. Normal steel shell wall thickness within 0.4mm and air pressure of 0.5-0.8MPa can meet the requirements for use. In special cases where the wall thickness is greater than 0.4mm and the material is relatively hard, an air source of 0.8-1.2MPa can be selected 2. The pressure values of different steel shells are set differently. When the pressure is low, they cannot roll, but when the pressure is high, they will roll and break (the pressure that has been adjusted before leaving the factory can meet 95% of the steel shell, and the pressure can be adjusted in special circumstances) |

Usage Environment | It is recommended to have an ambient temperature of 25 ± 3 ℃, humidity of 30-90RH, and no vibration or electromagnetic interference |

Applicable Batteries | 10mm -50mm, L20mm - L140mm, such as 3260, 4680, 18650, 21700 |

Groove Depth | adjustable from 0.8-2.0mm |

Roll groove widt | standard 1.2mm, can be designed to 0.9-1.5mm according to requirements |

Roll Cutter Life | ≥ 100000 times |

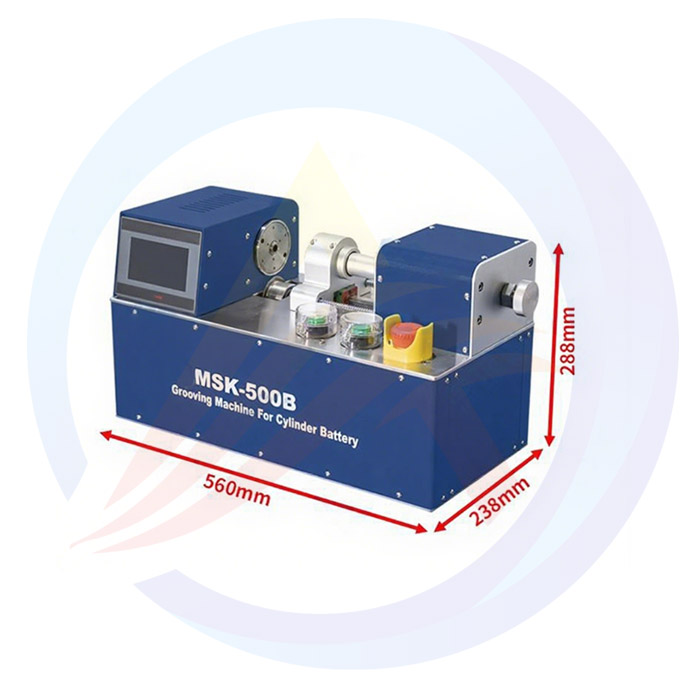

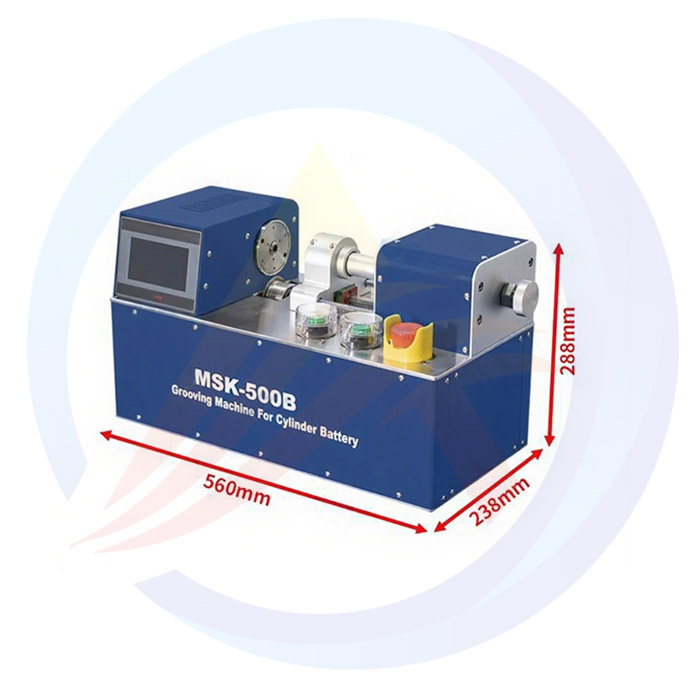

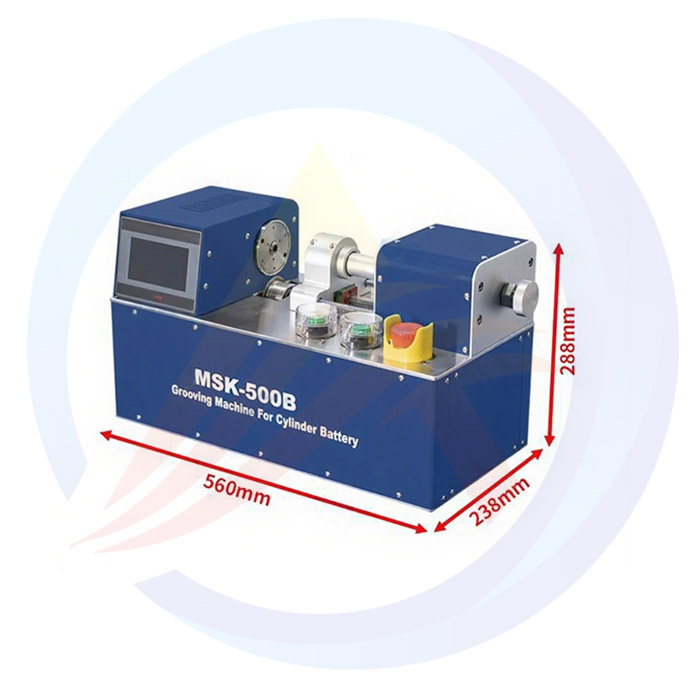

Equipment Size | L560mm * W238mm * H288mm |

Weight | 40KG |

FAQ

1.What is a battery grooving machine

Battery grooving machine is a device designed for battery shell processing, which is mainly used to open grooves of specific shape and depth on the battery shell to optimize the internal structure of the battery and improve the space utilization rate. It uses a precise mechanical structure and efficient cutting technology to precisely control the size and position of the notch, ensuring the integrity and performance of the battery case. The battery slotting machine is widely used in the battery manufacturing industry and is an important tool to improve the production efficiency and quality of the battery.

2.The role of the battery grooving machine

Battery grooving machine plays a key role in the battery manufacturing process. It is mainly used to precisely open notches on the battery housing to optimize the internal structure of the battery, improve space utilization, and ensure the accuracy and safety of the battery assembly. Through the fine slotting process, the battery slotting machine helps to improve the overall performance and reliability of the battery, and is an indispensable important equipment in the battery production.

3.Battery grooving process

Description of the working process of the battery slotting machine: After automatic feeding, the battery is accurately positioned to the processing area, and the high-speed rotating tool is precisely slotted on the surface of the battery housing according to the preset program. During the process, the intelligent control system monitors and adjusts in real time to ensure that the slot accuracy and depth meet the standard, and automatically cuts the material after completion. The entire process is efficient and accurate, which greatly improves the production efficiency and quality of the battery.