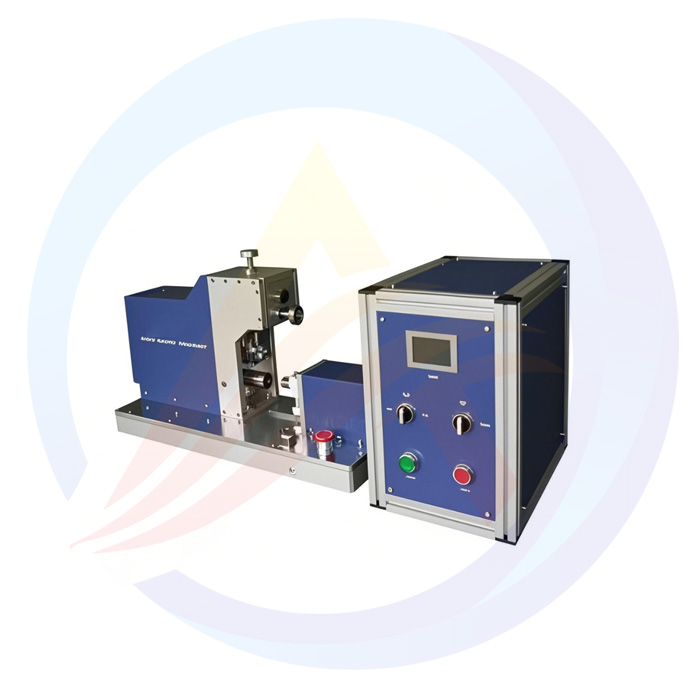

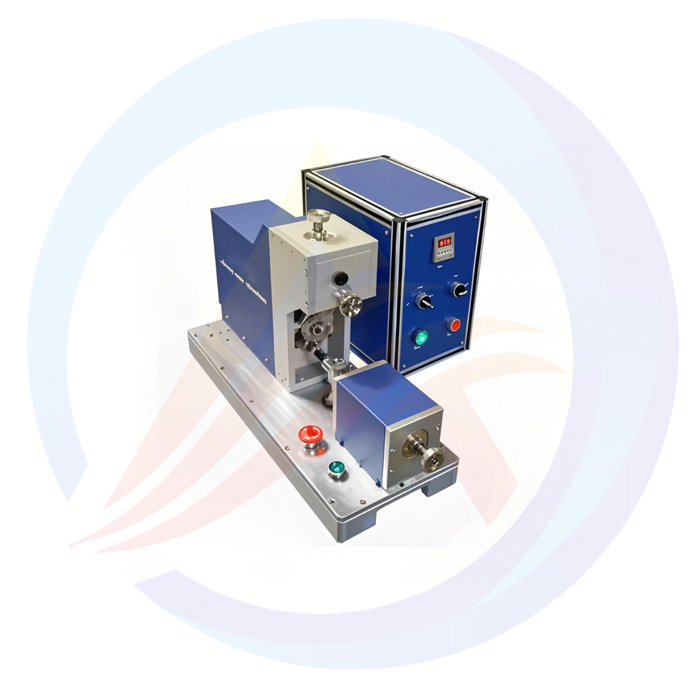

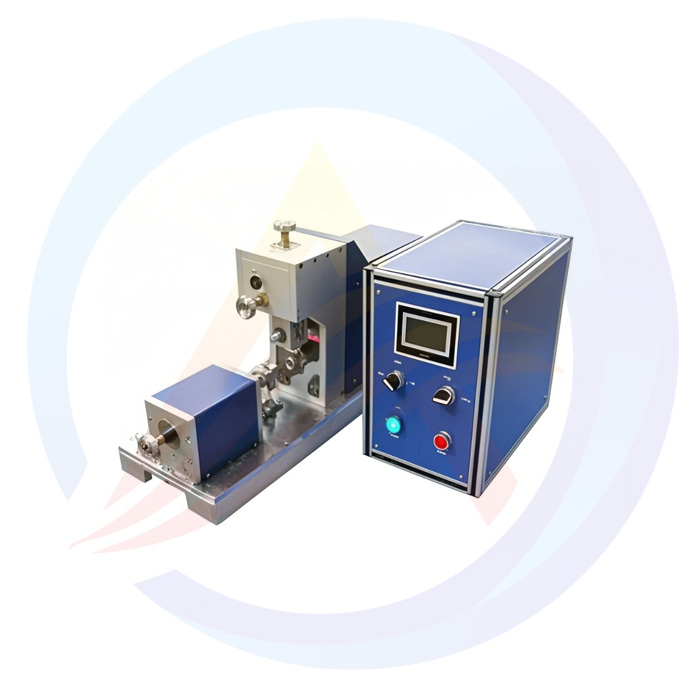

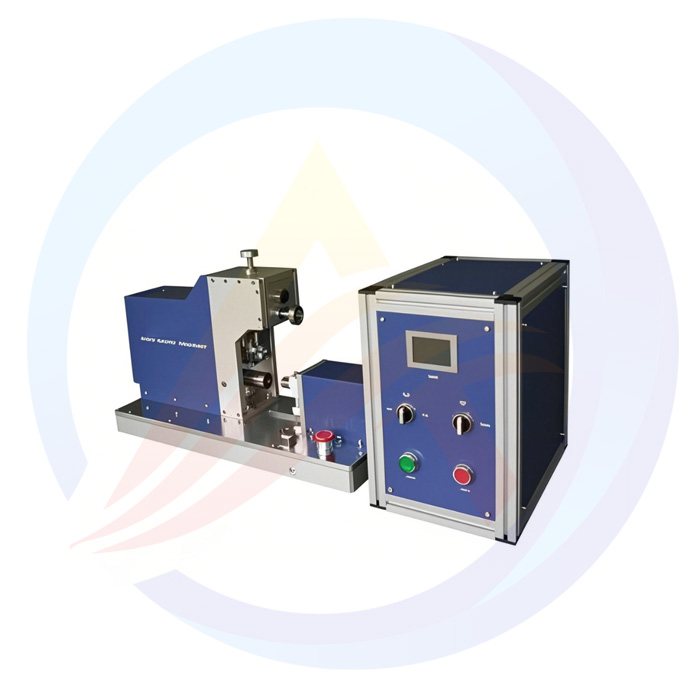

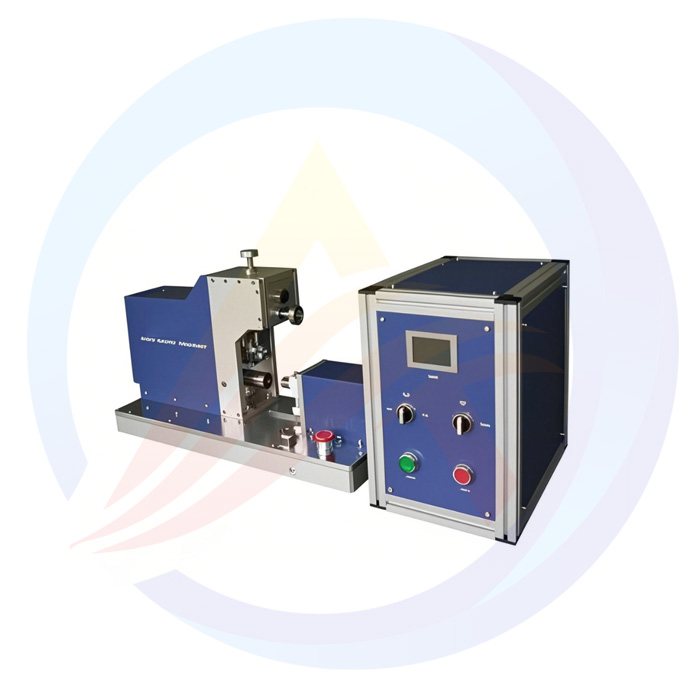

MSK-500 Series is semi-auto battery grooving machine. It is used for grooving various cylindrical cases including CR123,18650,21700,26650, 32650 and AA.

Product Model | AOT-MSK-500 |

Working Voltage | 110V/220V AC, 50/60Hz Single Phase |

Max. Power Consumption | 140W |

Air Pressure | >0.5 MPa is required Attention: If a gas cylinder is used instead of air compressor(pic2), a two-stage pressure regulator(pic1) must be installed on the gas cylinder to limit the pressure within the required working range for safe operation. |

Compatibility | CR123 / 18650 / 26650 / 32650 / AA (Please select the cell type in the option bar) |

Grooving Dimensions | Depth: 1.2 - 2.0 mm Width: 1.1 - 1.5 mm |

Grooving Accuracy | +/- 0.1 mm |

Grooving Blade Durability | >1 million times |

Productivity | 400 grooving per hour |

Product Dimensions | 600mm(L) x 230mm(W) x 350mm(H) (24" x 9" x 14") |

Net Weight | 68 kg (150 lbs) |

Company Profile

Xiamen AOT battery equipment Technology Co LTD was set up as a manufacturer in 2006. We have total manufacturing facilities of around 4, 000 square meters and more than 65 staff. Owning a group of experienced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy. AOT Battery has been focused on product development and operations of lithium battery and its surrounding, we supply full kinds of lithium-ion battery equipment, lab battery raw materials and lithium-ion battery research and development technology.

Exhibition

AOT Lithium Battery Equipment exhibition provides exhibitors and visitors with a comprehensive platform for display, exchange, cooperation and trade. By participating in the exhibition, enterprises can understand the industry dynamics, expand market channels, enhance brand image and promote technological innovation and industrial upgrading.

Certificate

Cooperative

FAQ

1.What is a Cylinder Cell battery Grooving Machine

Battery grooving machine is a device designed for battery shell processing, which is mainly used to open grooves of specific shape and depth on the battery shell to optimize the internal structure of the battery and improve the space utilization rate. It uses a precise mechanical structure and efficient cutting technology to precisely control the size and position of the notch, ensuring the integrity and performance of the battery case. The battery slotting machine is widely used in the battery manufacturing industry and is an important tool to improve the production efficiency and quality of the battery.

2.The role of the Cylinder Cell battery Grooving Machine

The battery grooving machine plays a key role in the battery manufacturing process. It is mainly used to precisely open notches on the battery housing to optimize the internal structure of the battery, improve space utilization, and ensure the accuracy and safety of the battery assembly. Through the fine slotting process, the cylinder cell battery grooving machine helps to improve the overall performance and reliability of the battery, and is an indispensable important equipment in the battery production.

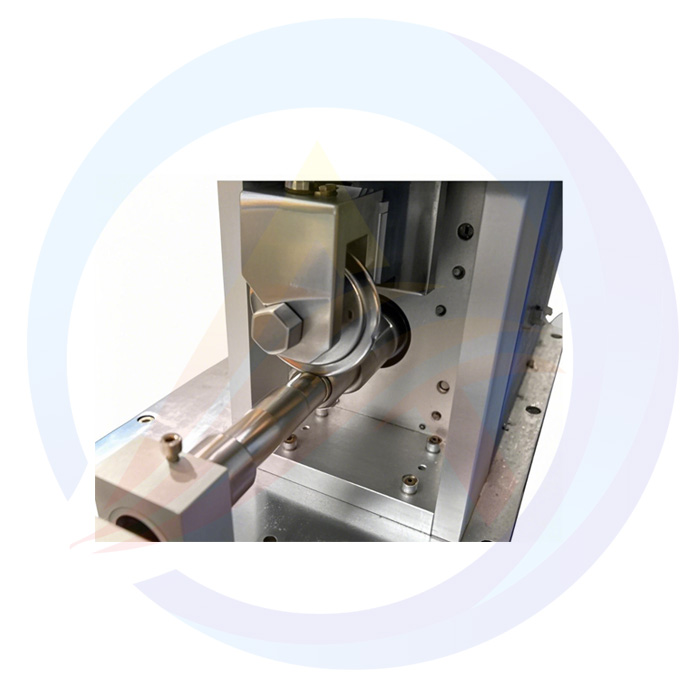

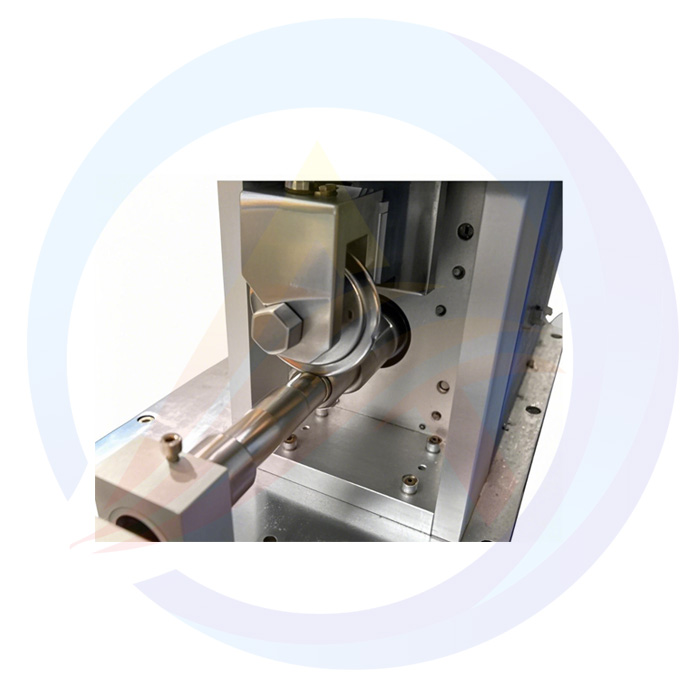

3.Cylinder Cell battery Grooving Machine process

Description of the working process of the battery slotting machine: After automatic feeding, the battery is accurately positioned to the processing area, and the high-speed rotating tool is precisely slotted on the surface of the battery housing according to the preset program. During the process, the intelligent control system monitors and adjusts in real time to ensure that the slot accuracy and depth meet the standard, and automatically cuts the material after completion. The entire process is efficient and accurate, which greatly improves the production efficiency and quality of the battery.