A Battery Electrode Rolling Press is a key device in battery production. It compresses and flattens battery electrodes, usually those coated with active materials. By adjusting the pressure and gap between rollers, it increases electrode density, enhancing battery energy density and performance. Different models exist for various production scales, from small - scale lab units to large - capacity industrial ones.

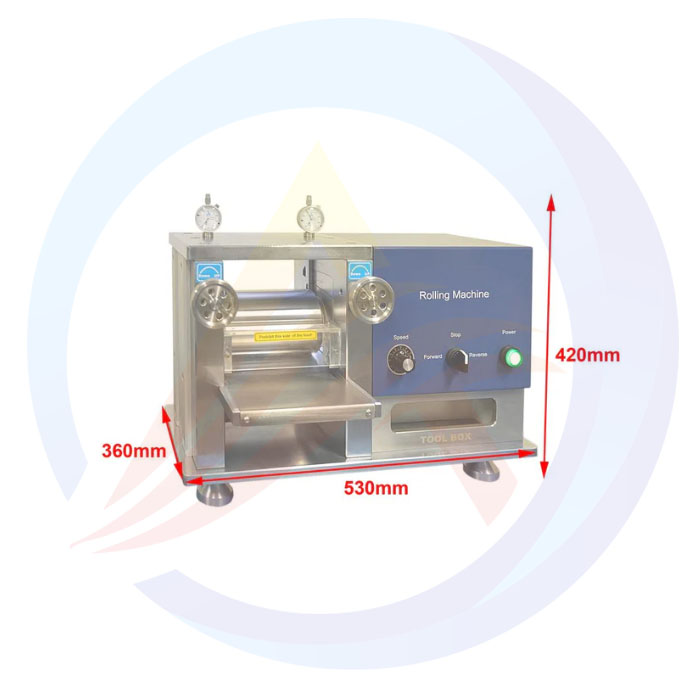

Product model | AOT-MSK-2150-DC |

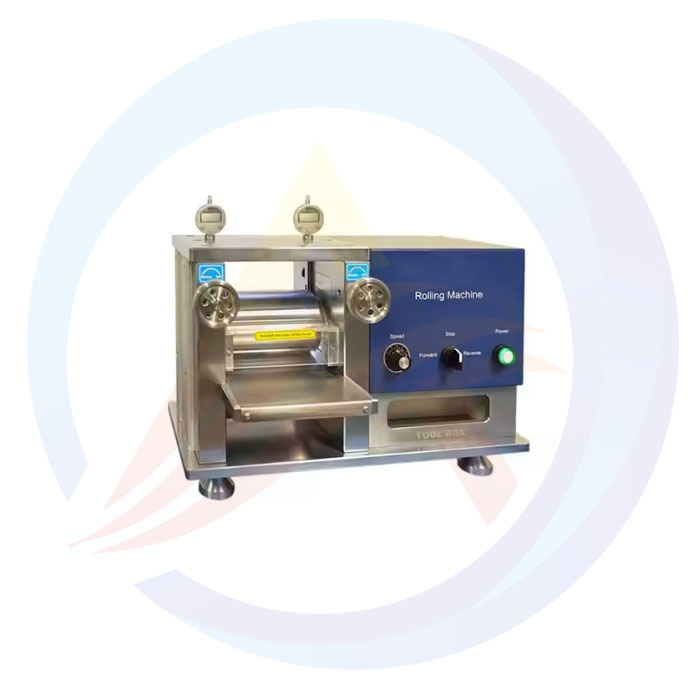

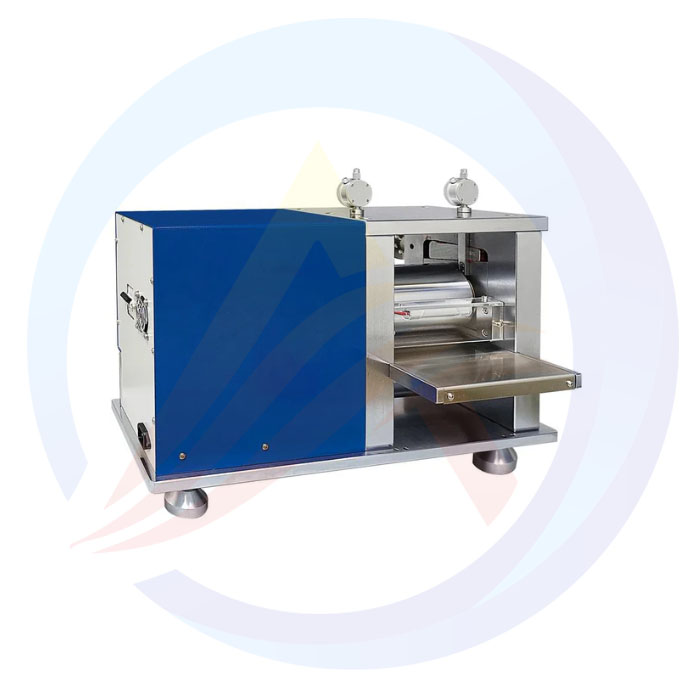

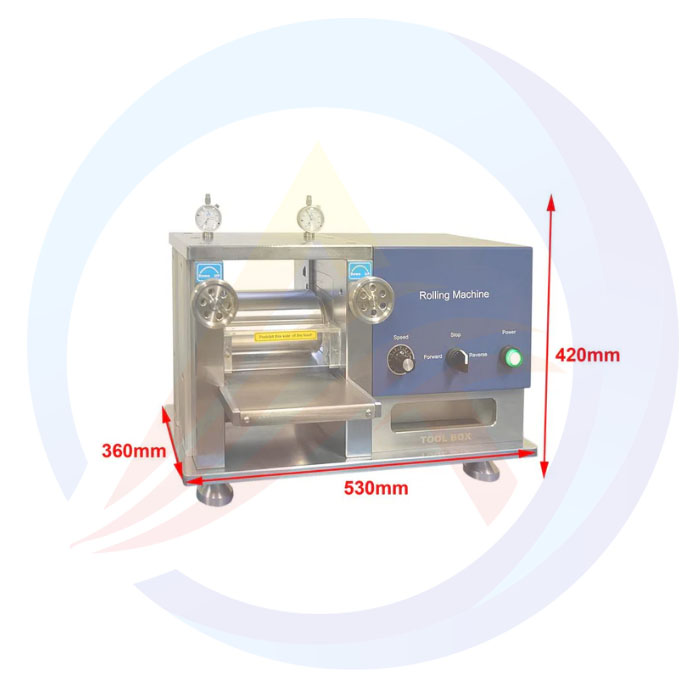

Structure

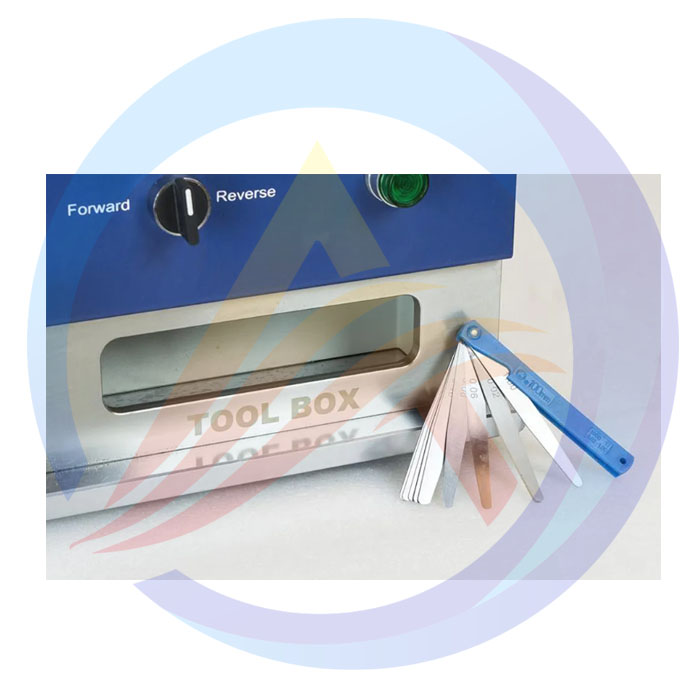

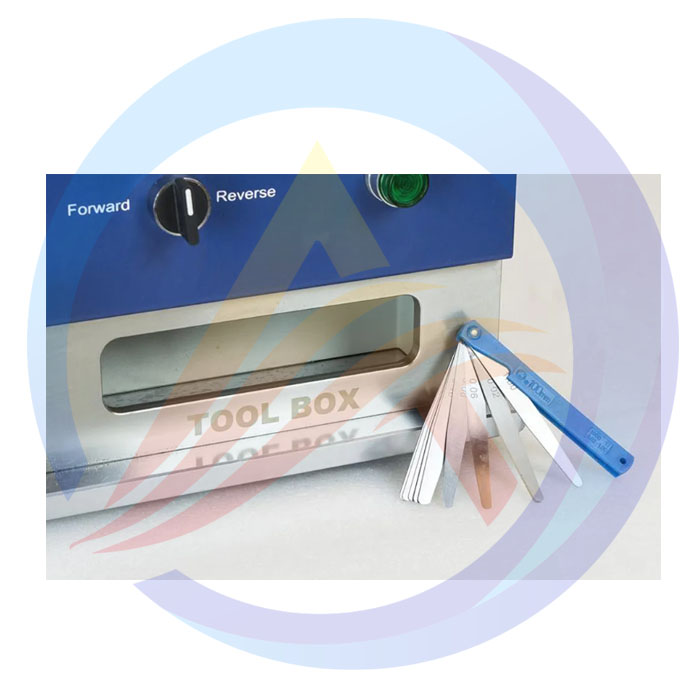

| Rolling Speed Adjustable (0 - 25 mm/ second) Heavy-duty steel frame, gears, and handle Roller size: 150mm width x 94mm Dia (dual rollers), made of hardened steel (RC > 60) with Cr electroplated coating Dual micrometer for accurate thickness adjustment in the range 0 - 3 mm. (Pic. 1) Built-in toolbox for easy operation & safety barricades (front and behind rollers) (Pic. 2) The lighting on the back of the roller for sample observation. (Pic. 3) |

Rolling Gap | 0 mm ~ 1.0mm |

Rolling Speed | Max. 50 mm/ second (Rolling Speed Adjustable)

Forward, Stop and backward switchable Forward, Stop and backward switchable |

Torque Capability | 850N |

Surface Hardness of Rollers | HRC 60-62 Never roll materials with hardness > 50HRC Note: The benchtop rolling press is not suitable for calendering thick metals. For applications with such needs, please consult with MTI engineers. |

Digital Micrometer | Range: 0 - 10mm Resolution: 0.01mm (or 0.001in) Unit interchangable (mm / in) Zeroing Power supply: CR2032 3V Li-ion battery Operating temperature: 0 ~ 40°C |

Company Profile

Xiamen AOT battery equipment Technology Co LTD was set up as a manufacturer in 2006. We have total manufacturing facilities of around 4, 000 square meters and more than 65 staff. Owning a group of experienced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy. AOT Battery has been focused on product development and operations of lithium battery and its surrounding, we supply full kinds of lithium-ion battery equipment, lab battery raw materials and lithium-ion battery research and development technology.

Exhibition

AOT Lithium Battery Equipment exhibition provides exhibitors and visitors with a comprehensive platform for display, exchange, cooperation and trade. By participating in the exhibition, enterprises can understand the industry dynamics, expand market channels, enhance brand image and promote technological innovation and industrial upgrading.

Certificate

Cooperative

FAQ

Q1.How should I maintain the Battery Electrode Rolling Press?

You can follow these guidelines:

Regular cleaning: Clean the machine regularly to remove dust, debris, and other contaminants. Use a brush or compressed air to clean hard-to-reach areas.

Lubrication: Apply lubricating oil or grease to the moving parts of the machine, such as bearings, gears, and rollers. This helps reduce friction and wear. Follow the manufacturer's recommendations for the type and frequency of lubrication.

Check for wear and tear: Inspect the machine regularly for any signs of wear and tear. Look for loose or damaged parts, worn-out belts, and misaligned components. Replace or repair any faulty parts to ensure smooth operation.

Alignment and calibration: Check the alignment of the rollers to ensure they are parallel and properly aligned. Adjust them if necessary.

Safety checks: Ensure that all safety guards, switches, and sensors are in place and functioning properly. Test emergency stops and other safety features regularly to ensure they are working correctly.

Training and operator awareness: Provide proper training to machine operators on the correct operation and maintenance procedures.

Q2. What is the difference between a battery electrode rolling press and a hydraulic cold press machine?

Both machines serve different purposes, the battery electrode rolling press relies on rotating rollers and high pressure, while the hydraulic cold press machine utilizes hydraulic pressure for gradual and controlled pressing operations.

Q3. How to choose a good roller press machine for battery?

You can consider the following factors:

Capacity: Evaluate the machine's capacity to meet your production requirements. Determine the desired output in terms of the number of batteries produced per unit of time and choose a machine that can handle that capacity.

Size and customization: Consider the size of the machine and whether it can be customized to suit your specific battery production needs.

Quality and durability: Look for a machine made with high-quality materials and that ensure durability and longevity. The machine should be able to withstand the heavy workload and demanding conditions of battery production.

Automation and control: Check if the roller press machine offers advanced automation features and control systems. Automation can improve efficiency, reduce human error, and enhance production consistency.

Safety features: Ensure that the machine has necessary safety features such as emergency stops, guards, and safety interlocks. Safety should be a priority to protect the operators and prevent accidents.

Service and support: Evaluate the reputation of the manufacturer or supplier of battery electrode rolling press . Consider their track record for after-sales service, technical support, and availability of spare parts.