In the lithium battery manufacturing industry, the battery stacking machine stands as a pivotal piece of equipment, playing a crucial role in enhancing production efficiency and ensuring product quality. As the new energy sector continues to expand, the lithium battery industry has entered the TWh era, imposing higher demands on the efficiency, precision, and stability of battery stacking machines.

I. Definition and Working Principle of Battery Stacking Machines

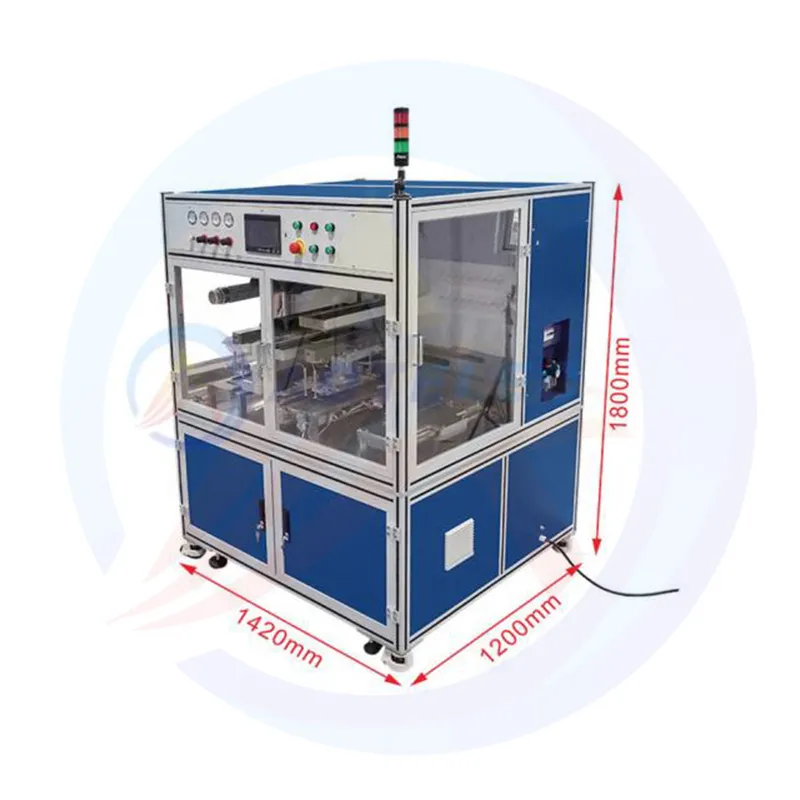

A battery stacking machine is a specialized device used in the manufacturing and assembly processes of batteries, articularly suited for large-scale or automated battery production lines. Its primary function is to automatically stack battery cells in a specific sequence to form the fundamental structure of a battery pack. Below is a brief explanation of its working principle:

1.Battery Cell Feeding: The machine receives individual battery cells from the feeding system, which can be manual or automated.

2.Alignment: Sensors and robotic arms are employed to precisely align each cell, ensuring the correct orientation.

3.Stacking: The aligned batteries are stacked in a specific order, typically with separator sheets in between to prevent short circuits.

4.Compression:Once the desired number of batteries is stacked, the machine applies controlled pressure to ensure a compact and secure stack.

5.Output: The completed stack is transferred to the next stage of the production line, such as welding or packaging.

II. Technical Features of Battery Stacking Machines

1.High Precision: Modern battery stacking machines can achieve a stacking precision of ±0.1 millimeters, ensuring consistency and stability in battery packs.

2.High-Speed Operation: Stacking speeds can reach 0.5 to 1 second per sheet, meeting the demands of large-scale production.

3.High Degree of Automation: The entire process from feeding to output is automated, reducing human error and improving production efficiency.

4.Flexibility: Capable of handling different types and sizes of batteries to accommodate various application requirements.

5.Intelligent Control: Equipped with advanced control systems that can monitor and adjust the stacking process in real-time to ensure product quality.

III. Application Fields of Battery Stacking Machines

Battery stacking machines are widely applied across multiple industries, especially in electric vehicles, consumer electronics, and renewable energy storage:

1.Electric Vehicles (EVs): The production of EV battery packs requires precise stacking of batteries to ensure optimal performance and safety.

2.Consumer Electronics: Devices such as smartphones, laptops, and tablets rely on compact and efficient battery packs, which are typically produced using battery stacking machines.

3.Renewable Energy Storage: Large battery systems used for storing solar or wind energy also benefit from the precision and efficiency of battery stacking machines.

4.Industrial Equipment:Batteries used in industrial machinery and equipment often require customized stacking configurations, which can be easily achieved with these machines.

IV. How to Choose the Right Battery Stacking Machine

Selecting the appropriate battery stacking machine involves considering multiple factors. Here are some key considerations:

1. Production Requirements

Production Scale: Large-scale production necessitates high-speed, fully automated stacking machines, while small-batch production may be better suited for semi-automatic or manual equipment.

Battery Type:Choose a stacking machine based on the type of battery being produced (e.g., cylindrical, prismatic, or pouch cells).

2. Technical Specifications

Stacking Speed:Ensure the stacking machine's speed meets the production line's requirements.

Stacking Precision:High precision is critical for ensuring consistency and stability in battery packs.

Compatibility:The stacking machine should be compatible with different battery sizes and types.

3. Brand and Manufacturer

Opt for well-known brands such as AOT, which typically offer high-quality products and comprehensive after-sales services.

4. Cost-Effectiveness

Purchase Cost:Select equipment that fits within your budget while considering long-term maintenance and operational costs.

Maintenance and Support: Choose manufacturers that provide comprehensive technical support and training to ensure the machine's long-term stable operation.

5. Future Expandability

Select a stacking machine with flexibility and expandability to adapt to future changes in production requirements and technological upgrades.

As a key piece of equipment in lithium battery manufacturing, the battery stacking machine continues to evolve in terms of technological advancements and application scope. Selecting the right stacking machine requires a comprehensive consideration of production requirements, technical specifications, brand reputation, and cost-effectiveness. With the ongoing development of new energy technologies, battery stacking machines will play an increasingly important role in improving production efficiency and ensuring product quality. In the future, with further advancements in intelligence and automation, battery stacking machines are poised to bring about more innovations and breakthroughs in the lithium battery industry.