1. What is Electrode sheet roller press machine

Electrode sheet roller press machine refers to the process of compacting lithium battery electrode sheets that have been coated and dried to a certain extent. After the electrode sheet is rolled, the energy density of the lithium battery can be increased, and the binder can firmly adhere the electrode material to the current collector of the electrode sheet, thereby preventing the loss of energy of the lithium battery caused by the detachment of the electrode material from the current collector of the electrode sheet during the cycling process. Before the lithium battery electrode sheets are rolled, the coated electrode sheets must be dried to a certain extent; otherwise, the coating on the electrode sheets will fall off the current collector during the rolling process.

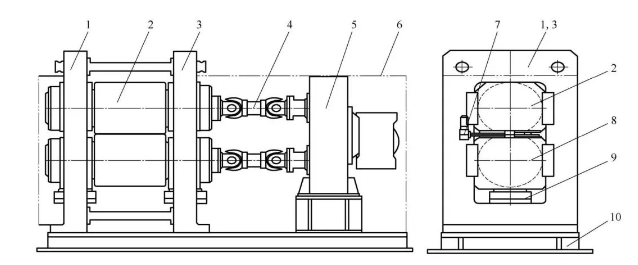

The structural composition

1 - Left rack 2 - Upper roller system 3 - Right rack 4 - Universal coupling 5 - Double output shaft reducer speed divider; 6 - Shield 7 - Roller gap adjustment mechanism 8 - Lower roller system 9 - Hydraulic Cylinder 10 - The base is shown in Figure 5. This roller press is mainly composed of the frame, rollers, main drive and other parts. The rack is the foundation of the entire system and needs to have sufficient rigidity and strength to reduce deformation. The hydraulic device applies the roller pressure to the rolls through the bearing housing. The motor and the reducer enable the two rolls to rotate synchronously, providing torque to the rolls and ensuring the realization of the continuous rolling process. The roll gap adjustment mechanism is composed of two gap adjustment inclined irons, which adjust the gap between the two rolls to meet the thickness requirements of different electrode sheets.

2. The principle of Electrode sheet roller press machine

The purpose of rolling is to make the active substance and the foil bond more dense and uniform in thickness. The roller pressing process must be carried out after the coating is completed and the electrode sheet is dried; otherwise, phenomena such as powder shedding and film layer detachment are likely to occur during the roller pressing process. The battery electrode sheet is a copper foil (or aluminum foil) coated with electrical slurry particles on both sides. The battery electrode strip undergoes two processes of coating and drying before being rolled. Before rolling, the electrical slurry coating on the copper foil (or aluminum foil) is a semi-flowing and semi-solid granular medium, composed of some unconnected or weakly connected individual particles or clusters, and has certain dispersibility and fluidity. There are gaps between the particles of the electrical slurry, which ensures that during the rolling process, the particles of the electrical slurry can undergo small displacement movements to fill the gaps and enable them to position themselves under compaction. Battery electrode sheet rolling can be regarded as a continuous rolling process of semi-solid electrical slurry particles in an open state. The electrical slurry particles adhere to the copper foil (or aluminum foil), are constantly bitten into the roller gap by friction force, and are compacted by the roller to form battery electrode sheets with a certain density.

The rolling of battery electrode sheets is quite different from that of steel. When steel is rolled, the rolled piece undergoes elastic deformation first after being subjected to an external force. When the external force increases to a certain limit, the rolled piece begins to undergo plastic deformation. When the external force increases, the plastic deformation increases. The purpose of longitudinal rolling in steel rolling is to achieve extension. During the steel rolling process, the molecules extend longitudinally and expand laterally, resulting in a decrease in the thickness of the rolled piece, but the density remains unchanged. Battery electrode sheets are coated with compound slurry on substrates such as aluminum foil or copper foil. electrode sheet roller press machine is to compact the electrical slurry particles on the electrode sheets.

3.Factors influencing Electrode sheet roller press machine quality

(1)The quality problems of electrode sheet roller press machine caused by the battery electrode sheet are mainly reflected in the uneven thickness of the electrode sheets after rolling. The inconsistent thickness leads to the inconsistent compaction density of the battery electrode sheets, and the compaction density is a key factor affecting the consistent performance of the battery. The uniformity of electrode sheet thickness includes transverse thickness uniformity and longitudinal thickness uniformity. The main influencing factors of the non-uniformity of the transverse thickness of the electrode sheet are the bending deformation of the rolls, the stiffness of the frame, the elastic deformation of the main load-bearing components, the roll pressure, the width of the electrode sheet, etc. During the operation of the rolling mill, due to the action of the roll pressure, the load-bearing components such as the rolls and the frame deform, and eventually manifest as the deflection deformation of the rolls, resulting in the phenomenon that the electrode sheet is thicker in the middle and thinner on both sides in the transverse direction.

(2)Other factors affecting the quality of electrode sheet roller press machine include tension control devices, deviation correction devices, slicing devices, dust removal devices, etc. During the rolling process, the electrode sheet needs to have a certain tension force. If the tension force is too small, the electrode sheet is prone to wrinkles; if it is too large, the electrode sheet is likely to be pulled apart. The dust removal device can ensure that no surface defects caused by impurities occur on the surface of the electrode sheet during roller pressing. The deviation correction device and the edge cutting device mainly affect the cutting dimensional accuracy of the electrode sheet.

4.What factors should be considered when choosing a electrode sheet roller press machine

(1)Production demand adaptation: Based on the characteristics of the positive and negative electrode materials (such as ternary, graphite slurry), select the corresponding roller surface material (hard chromium plating/ceramic coating) and precision (micron level); For laboratory scenarios, small desktop equipment (roller diameter ≤100mm) is available for selection, while for mass production, industrial-grade models (roller diameter 200-600mm, width 500-1500mm) are required.

(2)Core performance indicators: The rolling accuracy needs to be controlled within ±1μm, and it is equipped with a servo motor and a grating ruler for closed-loop control. The straightness of the roller surface is ≤0.005mm/m, and the surface roughness Ra is ≤0.2μm. The pressure range should match the compaction density of the material (for example, for graphite, 2.0-2.2g/cm³, corresponding to an adjustable range of 5-50 mpa).