In the thriving battery industry, selecting the right battery winding machine is crucial for manufacturers aiming to produce high - quality and efficient batteries. A good battery winding machine can enhance production efficiency, ensure battery consistency and reliability, and ultimately impact the competitiveness of the products in the market. Here are some key factors to consider when choosing a battery winding machine.

1. Understand Your Production Requirements

- Battery Type and Specifications: Different battery types such as lithium - ion, nickel - metal hydride, or lithium - polymer batteries have distinct winding requirements. Determine the specific dimensions, capacity, and chemical composition of the batteries you plan to produce. For example, lithium - ion batteries used in smartphones typically require precise winding of thin electrodes to accommodate the compact device size.

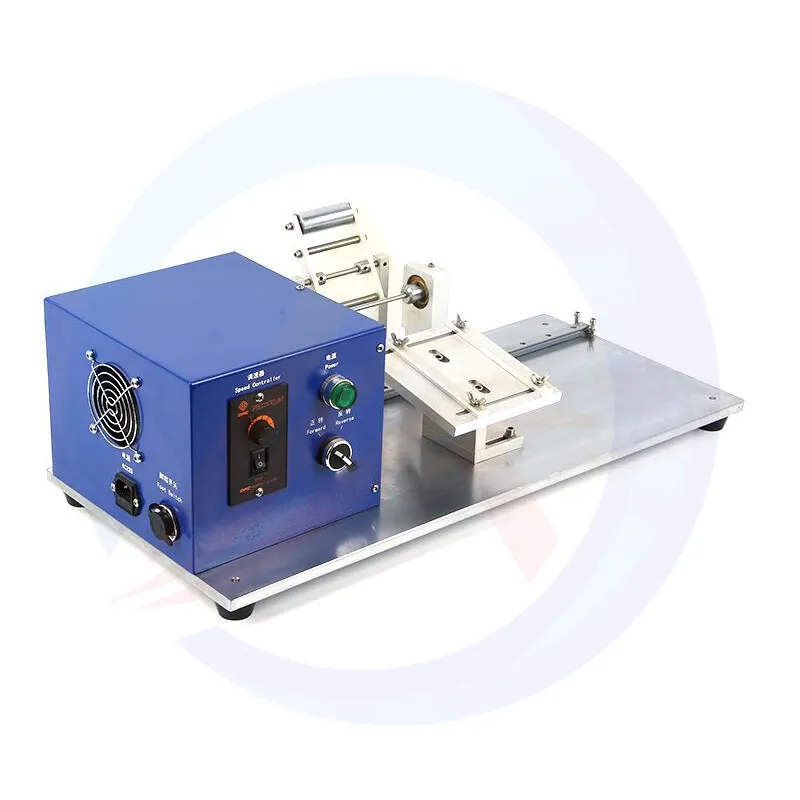

- Production Volume: Assess your production scale. If you are a small - scale manufacturer, a semi - automatic winding machine with moderate speed and flexibility may suffice. However, for large - scale production facilities, high - speed, fully automated winding machines with multiple channels and high - capacity feeding systems are necessary to meet the high output demands.

2. Machine Performance and Precision

- Winding Precision: The accuracy of the winding process directly affects battery performance. Look for machines with high - precision winding mechanisms that can control the tension of the electrode sheets and separator uniformly. Inconsistent tension can lead to electrode wrinkles or uneven winding, resulting in battery short circuits or reduced capacity. Advanced winding machines often feature sophisticated tension control systems using sensors and feedback loops to maintain precise tension throughout the winding process.

- Speed and Efficiency: Consider the winding speed of the machine. Higher speed machines can increase production output, but it's essential to balance speed with precision. A machine that operates too quickly may compromise winding quality. Evaluate the machine's efficiency in terms of downtime, maintenance requirements, and ease of operation. A highly efficient machine should have minimal downtime between production batches and require low - maintenance intervals.

3. Automation and Control Systems

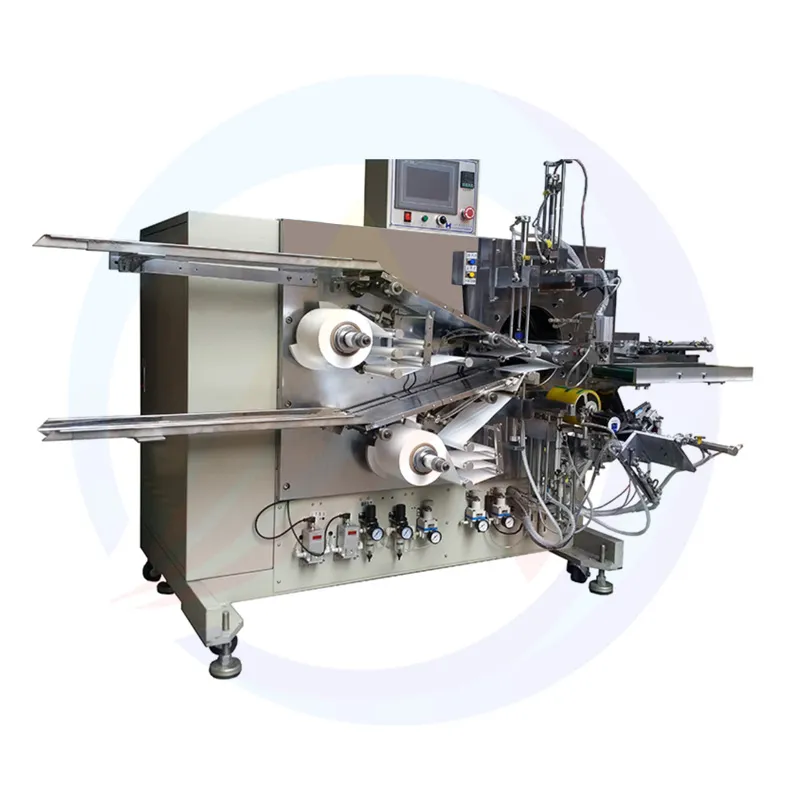

- Automation Level: Modern battery winding machines offer varying degrees of automation. Fully automated machines can handle tasks such as material feeding, winding, cutting, and even some post - winding processes like electrode assembly with minimal human intervention. This reduces human errors and increases production consistency. Semi - automated machines may require manual loading of materials or some manual adjustments during the winding process, which can be suitable for manufacturers who need some flexibility or have specific production scenarios.

- Control System: A reliable and user - friendly control system is vital. Look for machines equipped with advanced PLC (Programmable Logic Controller) systems or industrial computers that allow easy programming of winding parameters, monitoring of machine status, and real - time data acquisition. Features like touch - screen interfaces and remote monitoring capabilities can enhance the ease of operation and management of the winding machine.

4. Compatibility and Adaptability

- Material Compatibility: Ensure the winding machine can handle the materials used in your battery production. Different electrode materials and separators have varying physical properties such as thickness, flexibility, and adhesion. The machine should be able to accommodate these differences without requiring significant modifications. For instance, some machines are specifically designed to handle the highly flexible and thin lithium - metal electrode materials used in next - generation batteries.

- Process Adaptability: The battery industry is constantly evolving with new battery technologies and manufacturing processes emerging. Choose a winding machine that can adapt to potential process changes. Some machines offer modular designs that allow for easy upgrades or modifications to incorporate new winding techniques or accommodate different battery chemistries.

5. Machine Quality and Reliability

- Build Quality: Inspect the construction quality of the winding machine. Robust and durable materials should be used for the machine's frame and components to withstand the rigors of continuous operation. High - quality components such as precision - made bearings, motors, and sensors contribute to the machine's longevity and reliability.

- Brand Reputation and Support: Research the reputation of the machine manufacturer. Established brands with a good track record in the battery equipment industry are more likely to provide reliable machines. Additionally, consider the availability of after - sales support, including technical assistance, spare parts supply, and regular maintenance services. A reliable support network can help minimize downtime and ensure the smooth operation of the winding machine over its lifetime.

6. Cost - Benefit Analysis

- Purchase Cost: Compare the prices of different battery winding machines that meet your requirements. However, don't make the decision solely based on the initial purchase price. Consider the overall cost - benefit ratio.

- Operating Cost: Take into account factors such as energy consumption, maintenance cost, and consumable expenses. Some high - end winding machines may have a higher purchase price but offer lower operating costs due to energy - efficient designs and longer maintenance intervals.

- Return on Investment (ROI): Estimate the ROI based on the machine's impact on production efficiency, product quality, and market competitiveness. A machine that can consistently produce high - quality batteries at a faster rate may generate higher profits in the long run, justifying a higher initial investment.

By carefully evaluating these factors and conducting thorough research, you can select a battery winding machine that best suits your production needs and helps you achieve success in the competitive battery market.