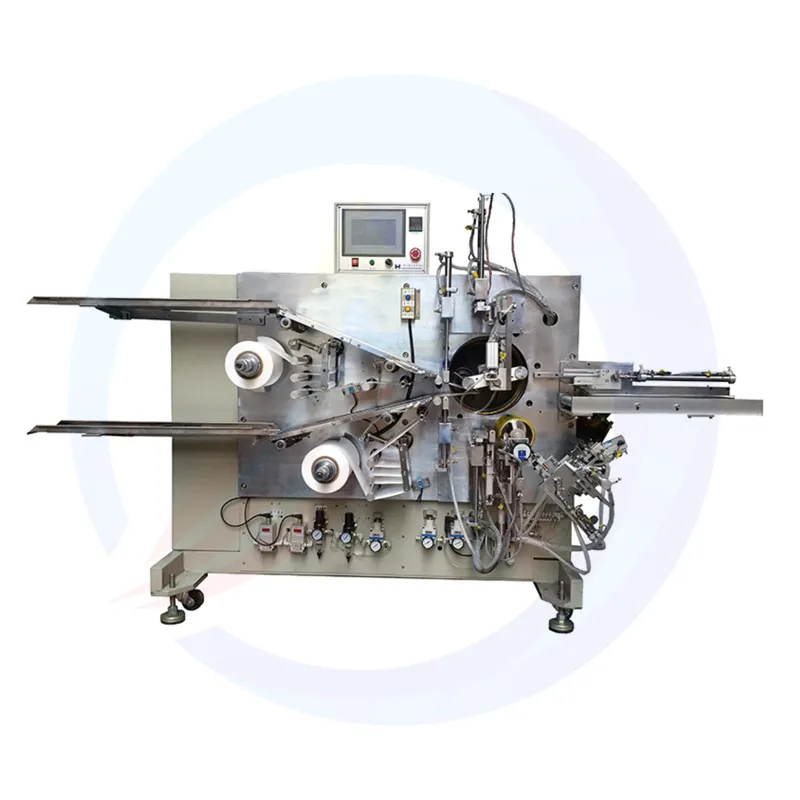

A battery winding machine is a precision-engineered industrial device used in the manufacturing of lithium-ion and other cylindrical or prismatic battery cells. The battery winding machine automates the process of winding electrodes (anodes and cathodes) and separators into tightly coiled structures, forming the core component of rechargeable batteries. The battery winding machine is critical for achieving high-quality, consistent cell production in industries such as electric vehicles, consumer electronics, and energy storage systems.

1.Key Features

Automation:Precision:

Advanced tension control systems and laser-guided alignment ensure uniform winding of electrodes and separators. Precune layering is vital to prevent short circuits, optimize energy density, and extend battery lifespan.

Flexibility:

The modern battery winding machines are modular and adaptable, capable of processing varying electrode widths, lengths, and cell diameters. Quick-change tooling allows manufacturers to switch between battery formats (e.g., 18650, 21700, or pouch cells) with minimal downtime.Quality Control:

Integrated vision systems and sensors monitor defects like misalignment, wrinkles, or contamination in real time. Faulty cells are automatically flagged or rejected, ensuring only compliant products proceed downstream.Safety:

Safety protocols include emergency stops, protective enclosures, and humidity/temperature controls to mitigate risks associated with flammable electrode materials (e.g., lithium metal).Efficiency:

Automated winding reduces material waste, accelerates cycle times, and lowers labor costs. High-throughput models can produce thousands of cells per hour, meeting demands for scalable battery production.

2.Applications

Battery winding machines are designed to:

Wind Electrodes and Separators:Precisely layer anode foil, cathode foil, and polymer separators into a "jellyroll" structure.

Ensure Consistent Tension:Maintain uniform tension during winding to prevent gaps or overlaps that degrade performance.

Customize Cell Designs:Support cylindrical, prismatic, or bespoke cell geometries for diverse applications.

3.Advantages

Enhanced Productivity:Continuous operation and high-speed winding (up to 10 meters per minute) outperform manual methods.

Superior Cell Quality:Repeatable precision minimizes internal resistance and maximizes energy output.

Cost Savings:Reduced scrap rates and labor dependency improve profit margins.

Industry Compliance:Adheres to ISO standards and safety regulations for global market compatibility.

Sustainability:Optimized material usage aligns with eco-friendly manufacturing goals.

3.Components and Workflow

Unwinding System:Feeds anode, cathode, and separator rolls into the machine with controlled tension.

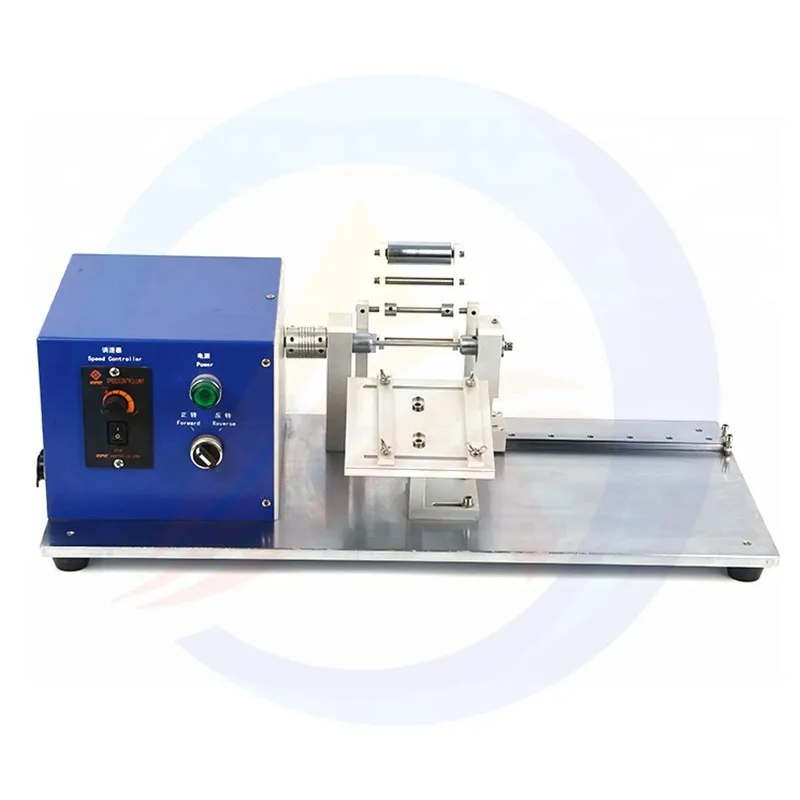

Alignment Mechanism:Laser or CCD sensors align materials to micron-level accuracy before winding.

Winding Head:A rotating mandrel coils the layered materials into the desired shape. Servo motors adjust speed and tension dynamically.

Cutting Unit:Trims electrodes/separators at specified lengths using precision blades or lasers.

Ejection System:Transfers finished cells to conveyor belts for subsequent processes (e.g., electrolyte filling, sealing).

Control Panel:User interface for programming parameters (e.g., winding layers, diameter) and monitoring diagnostics.

4.Workflow Overview

Material Loading:Electrode and separator rolls are mounted on the unwinding shafts.

Tension Calibration:Sensors set optimal tension to prevent material slippage or tearing.

Layered Winding:The mandrel rotates, winding anode, separator, and cathode into a tightly coiled structure.

Termination:Adhesive tabs or ultrasonic welding secure the cell’s outer layers.

Inspection:Vision systems scan for defects; approved cells proceed to packaging.

5.Industry Applications

Battery winding machines are indispensable for:

Electric Vehicles (EVs): Producing high-capacity cells for powertrains.

Consumer Electronics: Manufacturing compact cells for smartphones and laptops.

Energy Storage Systems (ESS): Building large-format batteries for grid storage.

6.Conclusion

A battery winding machine combines cutting-edge automation, precision engineering, and intelligent quality control to streamline battery cell production. By ensuring consistent, defect-free winding, this technology empowers manufacturers to meet rising demand for efficient, reliable energy storage solutions.

For businesses seeking to enhance battery production capabilities, investing in advanced winding machinery offers a competitive edge in cost, quality, and scalability. [Contact us] to explore tailored solutions for your battery manufacturing needs.