1. what is lithium battery spot welding machine

Lithium battery spot welding machine is specially used for spot welding of lithium battery electrodes, connecting pieces and other components. Spot welding is a resistance welding method, by applying a strong current to the welding part in a short time, the resistance heat generated by the current through the contact point of the welding part, so that the metal at the contact point is instantly heated to the melting state, forming a metal bond, so as to achieve a solid connection between the parts. With its precise current, time control and high stability, the lithium battery spot welding machine can meet the strict requirements for welding quality in the production of lithium batteries, ensuring high welding strength and low resistance to ensure the performance and safety of lithium batteries.

2. Working principle

The work of lithium battery spot welding machine is based on the principle of resistance thermal effect. When the device is energized, the transformer converts the ordinary voltage into low voltage and high current. The electrode conducts a strong current to the part of the lithium battery to be welded, and because there is a certain resistance in the part, the heat generated when the current passes through will rapidly increase the temperature. During the precisely controlled welding time, the heat accumulation causes the metal at the contact point to quickly reach the melting point and melt, forming a molten core. Subsequently, under the continuous action of electrode pressure, the molten core is cooled and solidified to form a solid solder joint. Throughout the process, the size of the welding current, the length of the welding time and the strength of the electrode pressure have a key impact on the quality of the welding spot, and the advanced lithium battery spot welding machine can accurately regulate these parameters to achieve high-quality welding results.

3. Common types

(1) Energy storage spot welding machine

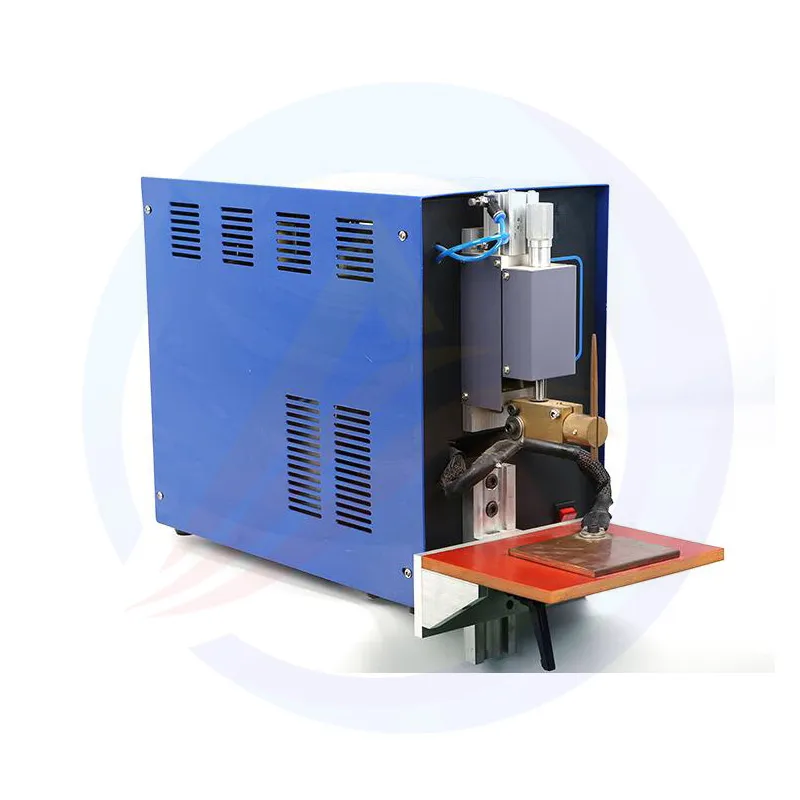

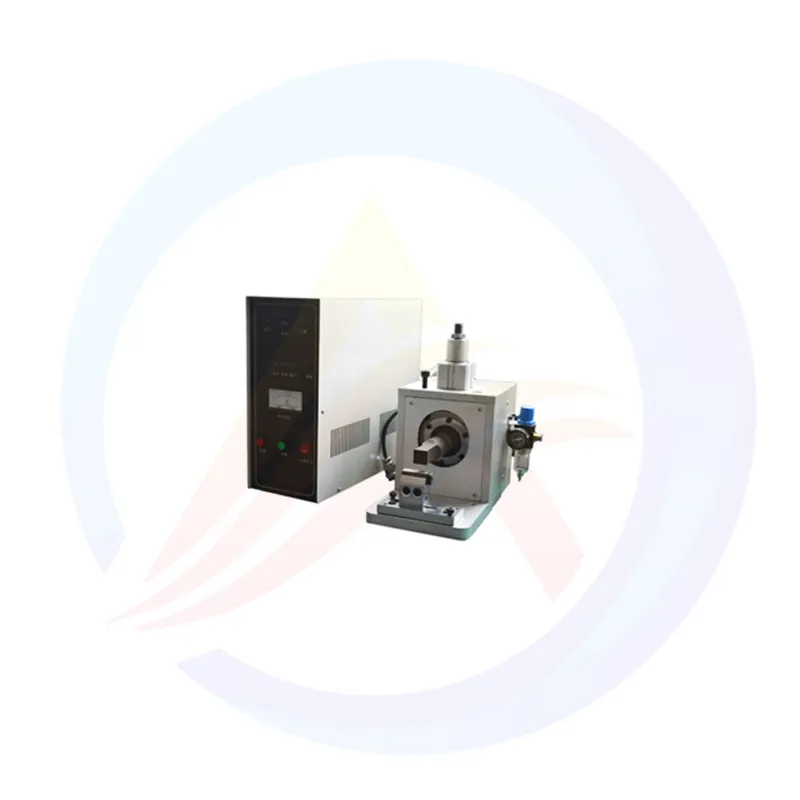

The energy storage spot welder first stores the electric energy in the capacitor. At the moment of welding, the capacitor quickly releases the stored electric energy and generates a large current pulse for welding. The advantage of this spot welding machine is that it can provide a strong current in a short time, and it is suitable for welding some lithium battery parts with high welding speed and thin thickness, such as the pole connection of small lithium batteries. It is characterized by a relatively simple equipment structure and low cost, but due to the capacity limit of the energy storage capacitor, the continuous welding capacity is limited, and it is not suitable for large-scale and high-frequency welding operations.

(2) Inverter spot welding machine

Inverter spot welder adopts advanced inverter technology, the power frequency alternating current is converted to high frequency alternating current first, and then rectified to direct current for welding after transformer step-down. The inverter technology greatly reduces the volume and weight of the transformer of the equipment, and improves the energy conversion efficiency at the same time. The inverter spot welding machine can more accurately control the waveform and size of the welding current, and has a faster current response speed, which can achieve accurate control of the welding process and high welding quality. It is suitable for the welding of various types of lithium batteries, whether it is a small consumer lithium battery, or the production of large power batteries, can show good performance, is currently a more widely used lithium battery spot welding machine type on the market.

4. Advantages in lithium battery production

(1) Efficient welding

lithium battery laser welding machine can complete the welding process in a very short time, which greatly improves the production efficiency. Taking large-scale lithium battery production as an example, the welding of tens or even hundreds of solder joints can be completed every minute, meeting the growing market demand for lithium battery production. Compared with the traditional welding method, the rapidity of spot welding avoids the thermal impact that may be caused by long-term welding on other components of the battery, and ensures the stability of the overall performance of the battery.

(2) High quality welding

Precise current, time and pressure control enables lithium battery spot welder to achieve high-quality welding results. The strength of the solder joint is high, and it can withstand large tensile and shear forces, ensuring that the connection part of the battery will not be loosened during use. At the same time, the resistance of the solder joint is small, which reduces the energy loss of the battery in the charging and discharging process, and improves the charging and discharging efficiency and service life of the battery. High-quality welding quality is also crucial to ensure the safety of lithium batteries, which can effectively reduce safety hazards such as short circuit and fire caused by poor welding.

(3) Strong adaptability

spot welder can flexibly adjust welding parameters according to the characteristics of different types of lithium batteries, such as electrode material, thickness, size, etc., to meet a variety of welding needs. Whether it is a small cylindrical lithium battery, square lithium battery, or soft pack lithium battery, it can achieve good welding results through the appropriate spot welder and parameter Settings. In addition, the spot welding machine can also be combined with automated production lines to achieve fully automated welding, further improving production efficiency and product consistency.

5. Technology development trend

(1) Intelligent control

With the development of artificial intelligence and automation technology, lithium battery spot welding machines are moving in the direction of intelligent control. The future spot welder will be equipped with an intelligent control system, which can monitor various parameters in the welding process through sensors in real time, such as current, voltage, temperature, pressure, etc., and automatically adjust welding parameters according to preset welding process requirements to achieve adaptive welding. Intelligent control can not only improve the stability of welding quality, but also find the abnormal situation in the welding process in time and alarm and treatment, reduce manual intervention and improve production efficiency.

(2) High-precision welding

In order to meet the needs of the continuous improvement of lithium battery performance, the requirements for solder joint quality are becoming higher and higher. The lithium battery spot welder will continue to improve the welding accuracy, further reduce the size deviation of the solder joint by optimizing the electrode design, improving the control algorithm of the welding power supply and other means, and improve the consistency and reliability of the solder joint. For example, in the production of some high-end lithium batteries, the diameter deviation of the solder joint is required to be controlled within a very small range to ensure the performance and safety of the battery. The development of high-precision welding technology will help promote the development of lithium batteries in the direction of higher energy density and longer service life.

6. Market status and competition pattern

At present, the globa llithium battery laser welding machine market shows a rapid growth trend. With the rapid development of the electric vehicle industry and the continuous expansion of the energy storage market, the demand for lithium batteries continues to rise, which has led to the prosperity of the lithium battery spot welder market. In terms of market competition pattern, enterprises in developed countries and regions such as Europe, the United States and Japan occupy a leading position in the field of technology research and development and high-end market. For example, some companies in Germany have deep technical accumulation in resistance welding technology, and the lithium battery spot welding machine produced by them is known for its high precision and high stability, and has strong competitiveness in the international high-end market.

In short, lithium battery spot welding machine plays an indispensable role in the lithium battery industry. Its efficient and high-quality welding capability provides a strong guarantee for the performance and quality of lithium batteries. It is believed that under the dual drive of technological innovation and market demand, lithium battery spot welder will continue to develop and progress, and make greater contributions to the prosperity and development of the lithium battery industry. If you are interested in lithium battery spot welder, or have related procurement needs, welcome to pay attention to our website at any time to learn more product information and industry trends. We will be happy to provide you with quality products and services, and work with you to create a better future for the lithium battery industry.