Single Point Pneumatic Spot Welder AOT-MSK-330A is a widely popular AC pulse spot welding machine, specially designed for the needs of nickel cadmium, nickel hydrogen, and lithium batteries. It is controlled by a microcomputer microcontroller and has more stable and reliable performance. It is used for welding the negative shell and tab of columnar batteries.

Core functions

Single Point Pneumatic Spot Welder specially designed for cylindrical lithium batteries (such as 18650, 21700, 26650, etc.), precise welding of battery electrodes (positive and negative electrodes) and nickel sheets/wires is achieved through resistance spot welding principle, ensuring low resistance and high-strength electrical connection.

Features

Pneumatic pressurization system:Pneumatic Spot Welder electrode is driven by a precision cylinder, and the pressure is stable and adjustable (usually within the range of 0-300N), ensuring uniform pressure on the contact surface between the electrode and the battery during welding, and avoiding virtual welding or over welding. Compared to manual welding, pneumatic systems provide higher consistency and repeatability accuracy.

Single point welding mode: welding one point at a time, suitable for small batch production, R&D testing, or repair scenarios, with strong operational flexibility. Supports single pulse/multi pulse welding mode, suitable for nickel sheets of different thicknesses (0.1~0.3mm) and battery models.

Intelligent control system:

microprocessor (MCU) control, digital parameter setting:

Welding current (adjustable from 1000 to 3000A)

Welding time (graded from 1 to 99ms)

Pressure holding time (maintaining pressure to prevent splashing)

The LCD touch screen monitors parameters in real-time and supports storing multiple sets of welding formulas.

High energy welding power supply: using medium frequency inverter DC technology (MFDC), it is more energy-efficient than traditional AC welding machines, with stable output, small heat affected zone, and reduced risk of battery damage. Fast response speed (above 1kHz), suitable for welding high conductivity materials.

Safety protection design: electrode insulation protection to prevent short circuits. Over current/over temperature automatic protection with emergency stop switch. Foot switch+dual hand start dual safety to avoid accidental operation.

Specification:

Product Name | Single Point Pneumatic Spot Welder AOT-MSK-330A |

Power Supply | 220-240V, Single Phase 50/60Hz |

Max. Power | 3kw |

Welding Current | 0-99A |

Welding Thickness | Suitable for various welding plates with a thickness of less than 0.15mm |

Welding Needle Diameter | Φ 2.5mm |

Scope of Application | Suitable for welding the negative electrode of cylindrical battery cells with 18650 and 21700 specifications. Customization is required for other sizes |

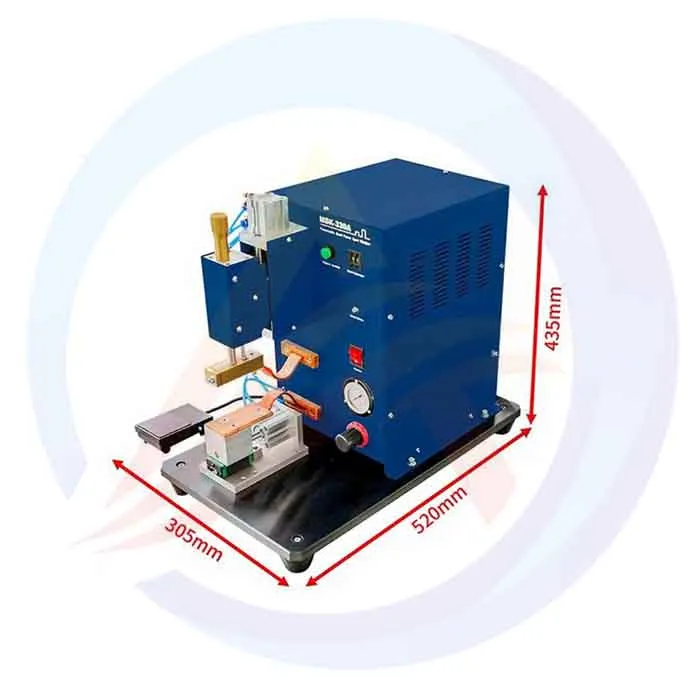

Equipment Size | W305 * D520 * H435mm |

Weight | 35kg |

Usage environment | Suggested ambient temperature 25 ± 3 ℃, humidity 30~90RH, no vibration and electromagnetic interference |

Air Source | 0.5-0.8MPa dry compressed air |

Typical application scenarios of AOT-MSK-330A

Assembly of lithium battery PACK: nickel sheet connection for series/parallel battery packs.

Maintenance and sample production of power battery modules (electric tools, electric vehicle battery packs).

Laboratory research and development, small-scale trial production, and educational training.