1. Introduction

As the core energy storage device for new energy vehicles, energy storage power stations, and portable electronic equipment, lithium-ion batteries have their energy density, cycle life, and safety directly determining the development ceiling of downstream industries. Nickel foam relying on its "structure-performance" synergistic advantages, has shown outstanding performance in solving problems such as low efficiency of traditional lithium-ion battery current collectors and insufficient utilization of active materials. It has become a key auxiliary material for the research and development of high-performance lithium-ion batteries. This paper analyzes its core characteristics, mechanism of action, and application progress.

2. Basic Analysis of Foam Nickel

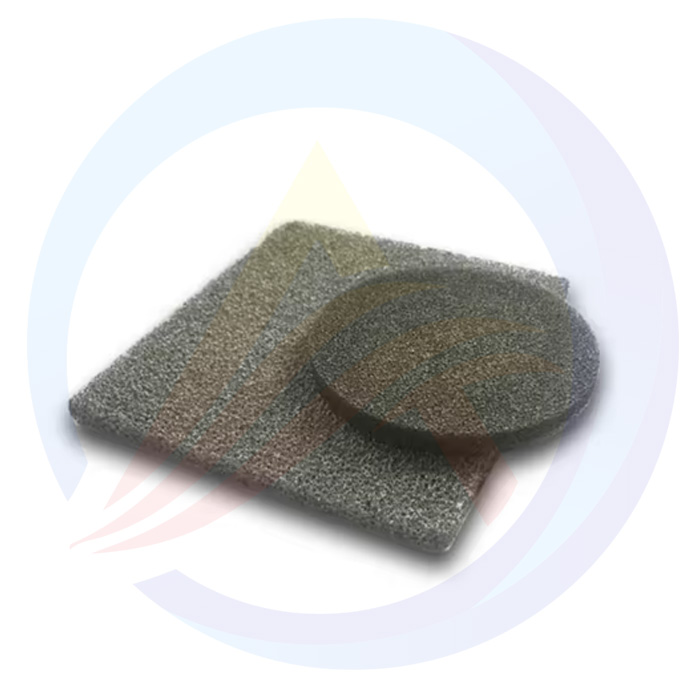

2.1 Structure and Properties

Foam nickel exhibits a three-dimensional interconnected network structure, with a typical porosity of 80%-95%, a specific surface area of up to 1-5 m²/g, a resistivity as low as 5-10 μΩ·cm at room temperature, and a tensile strength of approximately 15-30 MPa. The high porosity enables high loading of active materials (such as sulfur cathodes and silicon-based anodes) in lithium-ion batteries (20%-40% higher than traditional aluminum foil current collectors); the excellent electrical conductivity and mechanical strength can reduce electron transmission loss, while withstanding the volume expansion of electrodes during charge-discharge cycles, providing structural support for the long-term stable operation of batteries.

2.2 Preparation Processes

The mainstream preparation methods are divided into electrodeposition and chemical reduction:

Electrodeposition Method: Using polyurethane foam as the substrate, a nickel layer is deposited on the skeleton surface through an electroplating process, followed by high-temperature degreasing and reduction sintering to form foam nickel. The product purity can reach over 99.5%, with an aperture uniformity error of less than 5%. However, the investment in electroplating equipment is high, and the production cost per ton is approximately 30,000-50,000 RMB;

Chemical Reduction Method: Nickel salt solution is mixed with a reducing agent (such as sodium hypophosphite), and a reduction reaction occurs on the surface of the porous template to form a nickel layer. The cost is only 60%-70% of that of the electrodeposition method, making it suitable for 10,000-ton scale mass production. However, the product purity is easily affected by impurities, and microstructural shedding may occur during long-term use.

The selection of the two processes needs to be comprehensively determined based on the application scenario of lithium-ion batteries (e.g., power batteries have high requirements for purity, while energy storage batteries focus more on cost).

3. Mechanism of Action in Lithium-Ion Batteries

3.1 Role as Electrode Current Collector

When used as a cathode or anode current collector, the three-dimensional network structure of foam nickel can construct a "three-dimensional conductive network". The electron transmission path length is shortened by 40%-60% compared with traditional metal foils (such as aluminum foil and copper foil), reducing the battery internal resistance by 15%-25%; at the same time, its porous structure can accommodate more electrolyte, improving ion transmission efficiency. In the 1C rate charge-discharge test, the battery capacity retention rate is increased by 8%-12% compared with traditional current collectors, and the rate performance is significantly optimized.

3.2 Catalytic Activity Performance

In lithium-air batteries, nickel atoms on the surface of foam nickel can act as catalytic active sites for the oxygen reduction reaction (ORR) and oxygen evolution reaction (OER), reducing the reaction activation energy by approximately 0.2-0.3 eV and narrowing the battery charge-discharge voltage gap by 10%-15%; in lithium-sulfur batteries, foam nickel can inhibit the shuttle effect of lithium polysulfide and reduce the loss of active materials through chemical adsorption, reducing the capacity decay rate of the battery after 500 cycles to less than 20% (traditional batteries usually exceed 30%).

3.3 Comprehensive Impact on Battery Performance

From the perspective of actual test data, lithium-ion batteries using foam nickel current collectors:

The energy density is increased by 10%-30% (e.g., ternary lithium batteries are increased from 280 Wh/kg to 350 Wh/kg);

The cycle life is extended by 50%-100% (e.g., the capacity retention rate of lithium iron phosphate batteries after 2000 cycles exceeds 85%, while that of traditional batteries is approximately 60%);

The low-temperature performance is optimized, and the charge-discharge efficiency at -20℃ is increased by 15%-20% compared with traditional batteries, which can meet the usage needs of new energy vehicles in cold northern regions.

4. Research Progress and Application Cases

4.1 Cutting-Edge Research Trends

Current research focuses on the modification of foam nickel to break through performance bottlenecks:

Composite Modification: Combining graphene and carbon nanotubes with foam nickel to construct a "nickel-carbon synergistic conductive network", which increases the material's electrical conductivity by 30%-50% while enhancing corrosion resistance;

Surface Modification: Forming a protective layer on the surface of foam nickel through electroplating of cobalt, nickel-phosphorus alloy, etc. The corrosion rate in acidic electrolytes (such as lithium-sulfur battery electrolytes) is reduced to less than 0.01 mm/year (unmodified foam nickel is approximately 0.05 mm/year);

Structural Optimization: Developing gradient-pore foam nickel (small pore size on the surface, large pore size in the inner layer), which not only ensures the loading of active materials but also reduces electrolyte impedance. Relevant technologies have been verified in laboratory samples of enterprises such as CATL and BYD.

4.2 Practical Application Status

Foam nickel has achieved large-scale application in two types of lithium-ion batteries:

Lithium-Sulfur Batteries: A domestic enterprise uses carbon-coated foam nickel as the cathode current collector. The produced lithium-sulfur batteries have an energy density of 450 Wh/kg and have been installed in small UAVs, with the endurance time increased by 40% compared with traditional lithium-ion batteries;

Power Batteries: Tesla uses foam nickel-reinforced anode current collectors in the research and development of 4680 batteries, increasing the battery's rate charge-discharge capacity to 4C (full charge in 15 minutes) while reducing the risk of thermal runaway;

Currently, the core issue restricting large-scale application is still cost - the cost of foam nickel current collectors accounts for approximately 8%-12% of the total battery material cost (traditional current collectors only account for 3%-5%), and further cost reduction through process optimization is required.

5. Challenges and Prospects

5.1 Existing Problems

In addition to cost issues, there are two core challenges:

Insufficient Stability: In high-voltage (e.g., above 4.5 V) lithium-ion batteries, foam nickel is prone to interface reactions with the electrolyte, generating Ni³⁺ compounds, leading to an increase in battery impedance, and the capacity decay rate exceeds 25% after 1000 cycles;

Consistency Control: During large-scale production, the deviation of pore size and thickness of foam nickel is likely to exceed ±10%, resulting in performance differences between battery batches and affecting the quality control of downstream enterprises.

5.2 Future Development Directions

Process Cost Reduction: Developing "template-free electrodeposition technology" to eliminate the polyurethane foam substrate, which is expected to reduce production costs by more than 30%;

Multi-Scenario Adaptation: For new energy storage systems such as solid-state lithium batteries and sodium-ion batteries, developing foam nickel-derived materials with low impedance and high compatibility (e.g., nickel-based composite solid electrolyte carriers);

Industrialization Upgrade: Introducing AI visual inspection systems to control the consistency error of foam nickel products within ±5%, meeting the mass production needs of power batteries.