The principle of vacuum drying machine is an advanced material handling method that realizes high efficiency drying under reduced pressure conditions. This technology operates on fundamental thermodynamic principles where lowering environmental pressure correspondingly decreases liquid boiling points, enabling moisture evaporation at significantly reduced temperatures compared to conventional drying methods. Such characteristics make vacuum drying particularly suitable for processing thermally sensitive materials including biological specimens, electronic components, and specialty chemicals that are vulnerable to high-temperature degradation.

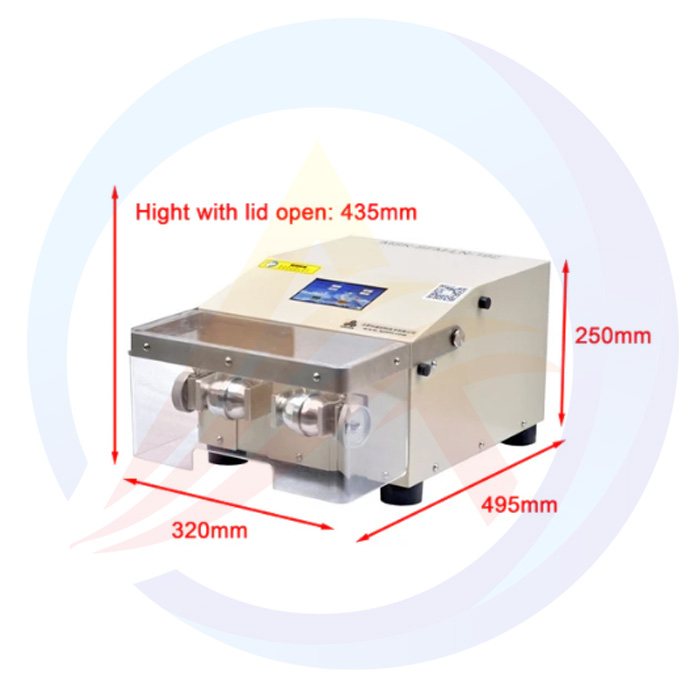

Modern vacuum drying systems incorporate four primary technical subsystems: the chamber structure, inner tank system, vacuum system, and temperature control system. The chamber utilizes high-quality steel plates with plastic-coated surfaces, ensuring both structural integrity and corrosion resistance. The inner tank employs 1Cr18Ni9Ti stainless steel, selected for its superior corrosion resistance and uniform heat distribution properties. Between the inner and outer chambers, ultra-fine glass wool insulation effectively minimizes heat loss while optimizing energy efficiency. The observation window features double-glazed design with tempered glass, allowing material monitoring without compromising vacuum integrity.

The vacuum system's core components include a vacuum pump, vacuum gauge, vacuum valve, and exhaust valve. Capable of achieving ultimate vacuum levels of 133Pa, this configuration meets most industrial drying requirements. With a pumping speed of at least 2L/S, the system rapidly establishes the desired vacuum environment. Operational protocols specify closing the vacuum valve before powering down the vacuum pump when reaching -0.1MPa, preventing oil backflow contamination. Optional accessories such as drying filter tanks and gas inlet valves enhance the system's material compatibility.

Temperature regulation employs Pt100 platinum resistance sensors with 100Ω resistance at 0℃ and a temperature coefficient of 0.3Ω/℃, providing precise chamber temperature monitoring. The PID control algorithm adjusts heating parameters through coordinated operation of proportional band (0-100%), integral time (1-4320s), and derivative time (0-1200s, typically 1/4 of integral time). This sophisticated control architecture maintains temperature stability within ±1.0℃ across the full RT-200℃ operational range.

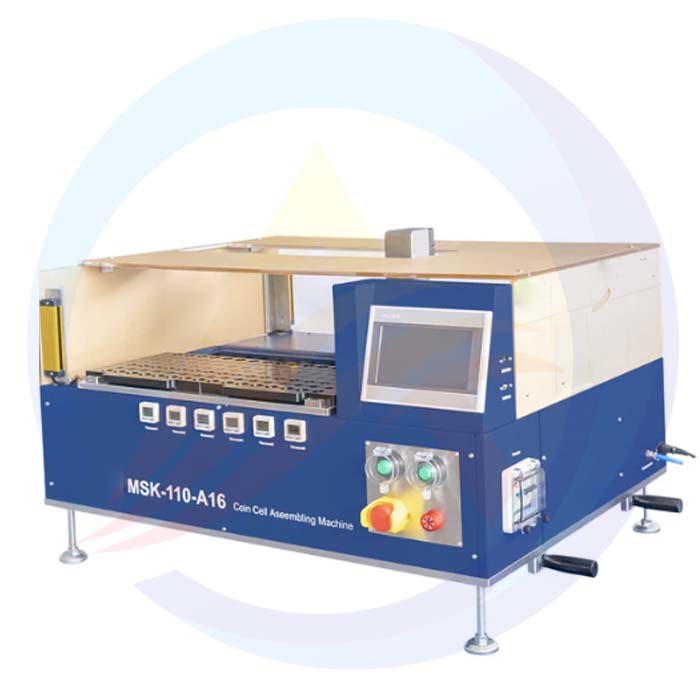

Vacuum drying oven user interface emphasizes operational simplicity through logically structured menus and intuitive control sequences. Temperature programming allows straightforward parameter adjustment, while the timing function accommodates extended processes up to 9999 minutes/hours. The auto-tuning feature automatically optimizes PID parameters when encountering temperature overshoot or fluctuation, significantly simplifying system calibration.Temperature measurement correction compensates for environmental variations, ensuring measurement accuracy.

Practical applications demonstrate the technology's advantages across multiple industries. For biological materials, vacuum drying preserves cellular integrity by avoiding thermal damage. Electronic manufacturing benefits from oxidation prevention during component drying. Chemical processing maintains compound purity through minimized thermal degradation. The two-stage temperature setting method proves particularly effective for low-temperature applications, initially establishing a sub-target temperature before final adjustment to prevent overshooting and accelerate stabilization.

Maintenance protocols focus on several critical aspects: regular vacuum pump oil level monitoring ensures proper operation; adjustable door latch mechanisms extend seal longevity; periodic lubrication of vent valves (using petroleum jelly) maintains smooth operation. For extended storage, neutral grease application on exposed metal surfaces and protective plastic covers prevent environmental damage to electrical components.

The comprehensive troubleshooting system addresses various operational issues: power supply failures examine circuit breakers and connections; temperature display abnormalities check sensor integrity and wiring; heating malfunctions verify parameter settings and component functionality; vacuum system problems inspect pump specifications, connection integrity, and seal condition.

Current technological evolution emphasizes intelligent control systems and precision engineering in vacuum drying machines. Advanced control algorithms integrated with sensor networks continuously improve temperature regulation accuracy for these machines. Modular designs of vacuum drying machines enhance system flexibility and maintenance accessibility, while energy-saving innovations in such equipment significantly reduce operational costs. These developments continue expanding vacuum drying applications, with vacuum drying machines playing a pivotal role in supporting advancements in materials science and industrial processing. As material technologies progress, vacuum drying systems—including state-of-the-art vacuum drying machines—will maintain their critical role in high-end manufacturing and scientific research through ongoing technical refinement and capability enhancement.