1, the basic working principle of lithium battery coating machine

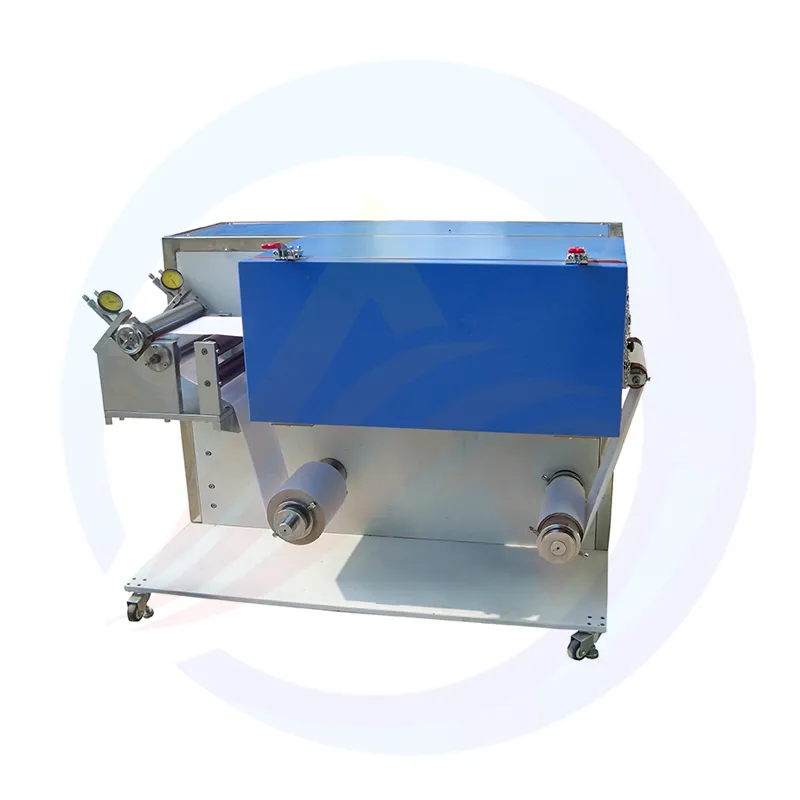

The lithium battery coater is mainly composed of a winding system, a coating system, a drying system, a winding system and a corresponding control system. The work flow begins with the unwinding system, and the rolled metal foil (usually aluminum foil or copper foil, which acts as the electrode collector) is released at a constant speed into the coating system. The coating head in the coating system accurately applies the evenly mixed electrode material paste to the metal foil surface according to the preset process parameters. Common coating methods are scraper coating, roll coating, slit coating, etc. Each method has its own unique advantages and application scenarios, designed to ensure that the stock can be stable and uniform thickness on the foil.

2, lithium battery coating machine in the electrode quality improvement of the key role

(1) Ensure coating uniformity

Coating uniformity is one of the core indexes of electrode quality of lithium battery. The uniform coating can ensure the uniform insertion and removal of lithium ions during the charge and discharge process of the electrode, thereby improving the overall performance of the battery. Lithium battery coating machine through the precision coating head design and advanced control system, precisely adjust the slurry flow, coating speed and coating gap and other parameters, the electrode material paste evenly coated on the metal foil, the error can be controlled in a very small range.

(2) Precise control of coating thickness

The coating thickness directly affects the active material load of the electrode, which determines the energy density and charge-discharge performance of the lithium battery. Lithium battery coater can accurately control the coating thickness according to different battery design requirements, ranging from a few microns to hundreds of microns. Through high-precision coating rolls and advanced thickness measurement feedback system, the coating thickness is monitored and adjusted in real time to ensure that the electrode coating thickness of each batch production meets the strict process standards. This precise control enables lithium battery manufacturers to flexibly adjust the energy density of the battery according to market demand and product application scenarios, meeting the diverse needs of different sectors, from consumer electronics to electric vehicles.

3, the contribution of lithium battery coating machine to the optimization of lithium battery performance

(1) Increase the energy density of the battery

By achieving high precision coating uniformity and precise thickness control, lithium battery coating machines help improve the utilization of electrode materials, thereby increasing the energy density of the battery. In the same electrode area and battery volume, the uniform and suitable thickness of the coating can hold more active substances, so that the battery can store and release more electrical energy during the charge and discharge process.

(2) Enhance the cycle life of the battery

The uniform and stable electrode coating can reduce the local stress and the non-uniformity of chemical reaction during the charging and discharging process of the battery, thus reducing the probability of failure phenomena such as pulverization and spalling of the electrode material, and significantly enhancing the cycle life of the battery. The lithium battery coating machine ensures the high quality of the coating during the production process, so that the electrode can maintain good structural integrity and electrochemical performance stability during the long-term charge and discharge cycle.

(3) Ensure the safety of the battery

The safety of lithium batteries is the first prerequisite for their application. In the electrode preparation process, if the uniformity and quality stability of the coating can be ensured, the safety hazards such as short circuit and overheating caused by local defects of the electrode can be effectively avoided.

4, lithium battery coating machine in the production efficiency improvement of the significant advantages

(1) High-speed and stable coating process

With the growing demand for lithium batteries in the market, improving production efficiency has become one of the key goals for manufacturers. Modern lithium battery coater has high-speed coating capability, which can greatly improve the coating speed under the premise of ensuring the coating quality. The coating speed of some advanced coating machine production lines can reach tens or even hundreds of meters per minute, which greatly reduces the production time of a single electrode.

(2) High degree of automation, reduce labor costs

The highly automated production process of the lithium battery coating machine significantly reduces the degree of manual intervention, reduces the error and uncertainty caused by manual operation, and also reduces labor costs.

5. The important position and prospect of lithium battery coating machine in the development of lithium battery industry

In the rapid development of the lithium battery industry, the electrode coating machine as a key equipment for electrode preparation, its technical level and performance directly affect the quality of lithium batteries, performance and production costs, and then determine the competitiveness of the entire industry. On the one hand, in terms of technological innovation, new coating technologies and materials, such as nano-coating technology and new drying technology, will be continuously introduced to further improve the quality and performance of electrode coatings; On the other hand, with the in-depth promotion of the concept of intelligent manufacturing, lithium battery coater will be deeply integrated with industrial Internet, big data, artificial intelligence and other technologies to achieve intelligent management and optimal control of the production process, and inject strong impetus for the sustainable development of the lithium battery industry.