What Is The Battery Electrode Slitting Machine?

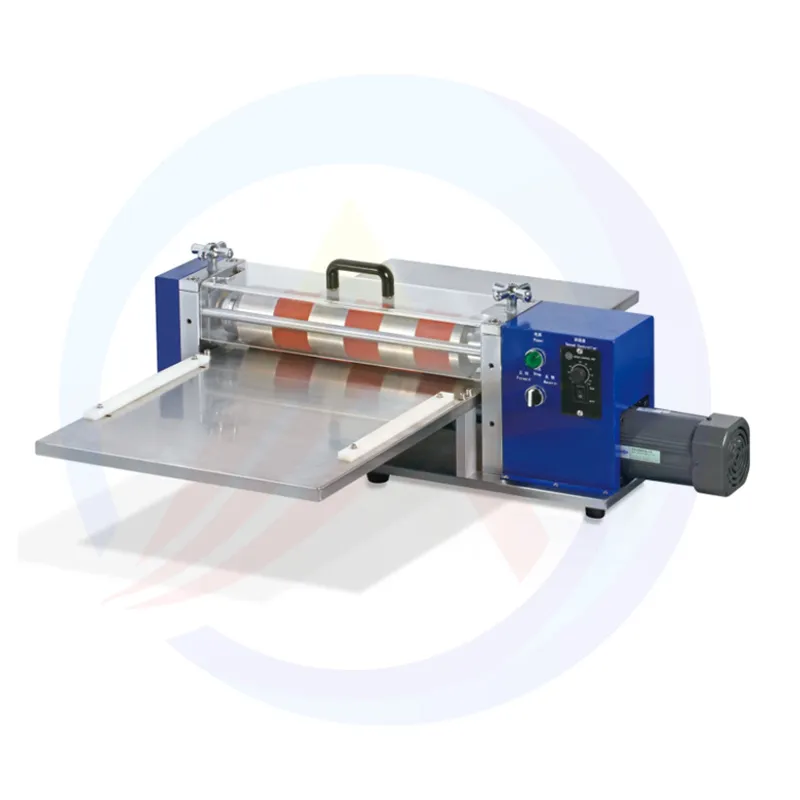

Battery electrode slitting machine, i.e. battery pole slitting machine, is an important equipment used for slitting electrode materials of lithium ion battery.

The main purpose

Battery electrode slitting machine is mainly used to accurately slit the electrode materials of lithium-ion battery (such as positive electrode slice, negative electrode slice), in order to meet the stringent requirements of electrode size in the battery manufacturing process.

Working Principle

Battery pole slitting machine realizes the slitting of electrode materials through a series of precise mechanical and electronic components working together. Its workflow is roughly as follows:

The electrode material is fed into the inlet of the slitting machine and is smoothly transported to the slitting area through the conveying device.

The slitting devices (e.g. upper and lower circular knives, single-piece rolling cutter, etc.) accurately slit the electrode material under the instruction of the control system.

The slit electrode material is collected to a predetermined location or container for subsequent processing and use.

The key performance parameters

The key performance parameters of the battery wafer slitting machine include slitting speed, slitting width accuracy, slitting wafer burr and so on. These parameters directly affect the productivity of the equipment and product quality.

Slitting speed: usually adjustable within a certain range to meet different production requirements. The slitting speed of some high-end equipment can reach 50m/min or higher.

Slitting width accuracy:usually within the range of ±0.1mm or less to ensure the dimensional accuracy of the electrode material.

Slitter blade burr: usually less than 10μm (outside the coating layer) to minimize the adverse effect on battery performance.

Equipment Features

High degree of automation: Battery pole slitter is usually equipped with automatic feeding, automatic slitting, automatic collection and other functions, which greatly improves the production efficiency.

High precision: Precision sensors and measuring lines are adopted to ensure the slitting precision of electrode materials.

Easy to operate: the equipment usually adopts touch screen or PLC control system, the operation interface is intuitive and easy to understand, which is convenient for operators to operate and maintain.

Energy-saving and environmental protection:some equipments adopt energy-saving design and environmental protection materials, which reduces energy consumption and environmental pollution.

Application Fields

Battery pole slitter is widely used in the manufacturing process of new energy batteries such as lithium-ion batteries and nickel-metal hydride batteries.

With the rapid development of new energy vehicles, energy storage systems and other fields, the market demand for battery pole slitting machine is also increasing.

How it works

Battery pole slitter usually works in concert with a series of precision mechanical and electronic components to realize automatic tracking and precise positioning of electrode materials. The following is a detailed explanation of how it works:

Automatic tracking

Sensor monitoring:

Battery pole slitting machines are equipped with high-precision sensors, such as photoelectric sensors and laser sensors, for real-time monitoring of the moving position and speed of the electrode material.

These sensors are able to sense the edges or specific markings of the electrode material, thus ensuring that the slitter can accurately track the movement of the material.

Control system adjustments:

The data collected by the sensors is transmitted to the machine's control system, which adjusts the slitter's trajectory and speed in real time based on this data.

Through precise algorithms and feedback mechanisms, the control system ensures that the slitter keeps moving in sync with the electrode material, enabling automatic tracking.

Precise Positioning

Positioning system:

Battery pole slitting machines are usually equipped with positioning systems, such as servo motors, stepper motors, etc., which are used to precisely control the position and speed of the slitting knife.

The positioning system can receive commands from the control system and accurately move to the preset position, thus ensuring that the slitting knife can accurately cut the electrode material.

High precision cutting:

Slitter knives usually use high-speed rotating disc cutting knives or blades, these cutting tools have very high hardness and sharpness, which can ensure the smoothness and precision of the cutting edge.

Through precise mechanical movement and control systems, the slitter is able to cut large quantities of electrode material in a short period of time while maintaining a high level of cut quality.

Feedback and Adjustment:

During the cutting process, the control system receives constant feedback data from the sensors, which are used to monitor cut quality and positional accuracy in real time.

If deviations or errors are found, the control system will immediately make adjustments to ensure the stability and accuracy of the cutting process.

The operation process of battery electrode slitting machine

Preparation stage

Material preparation:

Prepare the battery electrode materials to be slit, such as copper foil, aluminum foil and other pole pieces coated with active substances.

Ensure that the size, thickness and performance of the material meet the production requirements.

Equipment Inspection:

Check whether the parts of the battery electrode slitting machine are intact, such as cutter, sensor, control system, etc.

Confirm that the power supply and gas source of the equipment are connected properly, and turn on the equipment to warm up.

Parameter setting:

According to the production requirements, set the parameters of the slitting machine, such as cutting width, speed, tension, etc..

Debug the automatic deviation correction system of the equipment to ensure that the pole piece remains stable in the slitting process.

Installation and commissioning

Installation of cutter:

Install the cutting knife on the knife shaft of the slitting machine and adjust the cutting depth and angle.

Make sure the cutter is sharp and undamaged to minimize burrs and unevenness in the cutting process.

Adjust the fixture:

According to the size and shape of the electrode material, adjust the fixture of the slitter to ensure that the material can be stably fixed on the fixture.

Check the clamping strength of the fixture to avoid over-tightening or over-loosening which may cause deformation or damage to the material.

Commissioning equipment:

Start the slitting machine for no-load operation and check whether the various functions of the equipment are normal.

If necessary, make fine-tuning to ensure the cutting accuracy and stability of the equipment.

Slitting operation

Place the material:

Place the electrode material on the fixture of the slitting machine and clamp it.

Make sure the edge of the material is aligned with the cutting line to avoid cutting deviation.

Start the machine:

Press the start button of the slitter to start the cutting operation.

During the cutting process, pay close attention to the operating status of the equipment and the quality of the cut.

Collecting and Organizing:

After the cutting is completed, collect the cut electrode material and organize it.

Check whether the cutting edge is smooth and burr-free, and measure whether the cutting size meets the requirements.

Quality monitoring and maintenance

Quality monitoring:

Regularly sample the cutting quality to ensure stable product quality.

If the cutting quality is found to drop or the equipment is abnormal, stop the machine in time to check and deal with it.

Equipment maintenance:

Regularly clean and maintain the slitting machine, such as cleaning the cutter and replacing worn parts.

Check whether the lubrication system and transmission system of the equipment are working properly to ensure that the equipment is in good operating condition.

Data Recording:

Record the key parameters and cutting quality data in the slitting process for subsequent analysis and improvement.

Safety Precautions

Personal protection:

The operator should wear protective glasses, gloves and other personal protective equipment to avoid injuries caused by splashes or debris generated during the cutting process.

Equipment safety:

Ensure that the safety protection devices of the equipment are intact and effective, such as emergency stop button, safety door, etc..

During the operation of the equipment, it is forbidden to touch the cutting area or carry out other dangerous operations.

Environmental Control:

Keep the operation area tidy and well ventilated to avoid accumulation of dust or harmful gases.

If flammable and explosive materials are to be handled, ensure that the operation area complies with the relevant safety regulations.

In summary, the operation process of battery electrode slitting machine needs to strictly comply with the specifications to ensure product quality and production safety. Through reasonable parameter settings, precise operation and effective quality monitoring and maintenance measures, the performance advantages of the equipment can be fully utilized to improve production efficiency.