1、Working Principle of the glove box

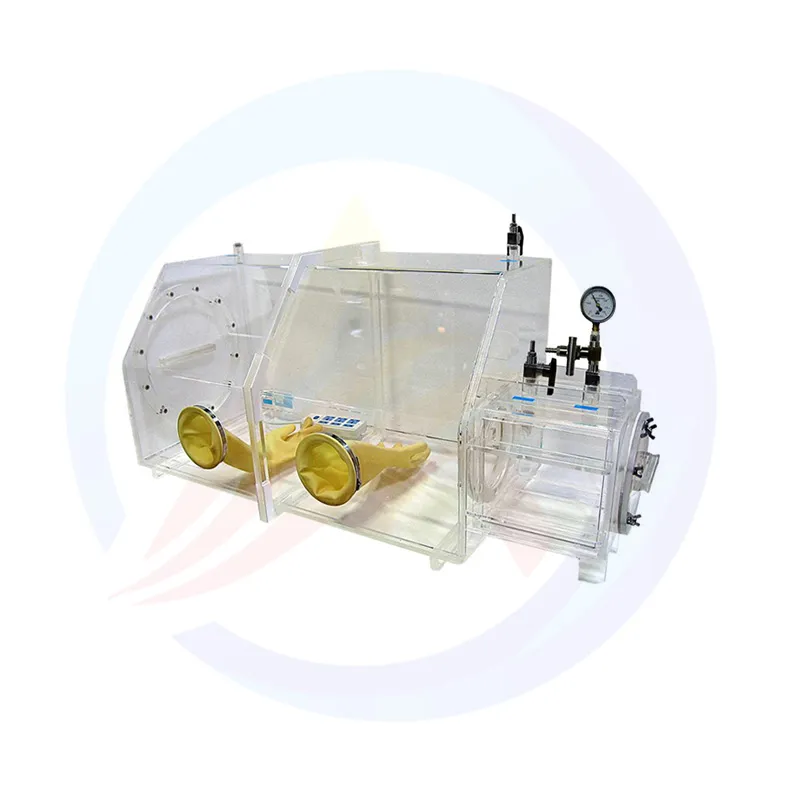

The glove box is mainly composed of the main box body, transition chamber, vacuum pump, gas purification system and control system, etc. Its working principle is to create an environment free of water and oxygen through a series of precise operations. Firstly, a vacuum pump is used to extract the air inside the box to create a vacuum state, minimizing the water vapor and oxygen content inside the box as much as possible and creating favorable conditions for subsequent gas replacement. When a certain vacuum degree is reached, high-purity inert gases such as nitrogen and argon are filled into the box. These inert gases have stable chemical properties and are not prone to react with other substances, providing a safe and stable environment for experiments and production.

To further reduce the water and oxygen content inside the glove box, a gas circulation purification system is equipped. The inert gas inside the box is continuously circulated through the gas purification system under the action of the circulating fan. The purification column in the purification system is usually made of materials such as molecular sieves. It is like an efficient "adsorber" that can effectively adsorb moisture and oxygen in the gas.

2、The glove box has multiple uses in the production of solid-state batteries

(1)In the processes of mixing, stirring and weighing solid-state battery materials, the glove box plays an indispensable role. Take material mixing as an example. The electrode materials and electrolyte materials of solid-state batteries are often composed of multiple components, and the uniform mixing of these components is crucial for battery performance. In the anhydrous and oxygen-free environment provided by the glove box, the mixing process can prevent the materials from reacting with water and oxygen from the outside. For instance, when mixing materials containing lithium, if in a normal environment, lithium is prone to undergo vigorous reactions with water and oxygen, generating impurities such as lithium hydroxide and lithium oxide. These impurities will alter the chemical composition and structure of the materials, thereby affecting the performance of the battery. In the glove box, materials can be fully mixed in a pure inert gas environment, ensuring the uniform distribution of each component and providing a high-quality material foundation for subsequent battery production. In the weighing process, the glove box is equally significant. Precise weighing is the prerequisite for ensuring the accuracy of material proportioning. The stable environment inside the glove box can prevent materials from absorbing moisture or adsorbing impurities due to external humidity, air flow and other factors, thereby ensuring the accuracy of weighing.

(2) Safety Fortress for Battery Assembly Once the material processing is completed, it enters the battery assembly stage. At this point, the glove box transforms into a "safety fortress". During the battery assembly process, various electrode materials, electrolytes and other components need to be precisely combined together. This process has extremely high requirements for the environment and must strictly isolate water and oxygen. Because electrode materials usually have strong activity, such as lithium metal anodes, they are extremely prone to oxidation in the air. Once oxidized, it not only reduces the conductivity of the electrode but also alters its chemical composition and structure, leading to a decrease in battery capacity and a shortened cycle life. Meanwhile, if the electrolyte (even the solid electrolyte in solid-state batteries may be affected by water and oxygen to a certain extent) comes into contact with water, it may undergo hydrolysis reactions, generating acidic substances or other harmful products. These products can corrode other components inside the battery, affecting its performance and stability.

(3) Reliable Assistant for Performance Testing After the production of solid-state batteries is completed, performance testing is an important step in evaluating their quality and performance, and the glove box is a reliable "assistant" in this process. Performance testing needs to be carried out in a stable and controllable environment to ensure the accuracy and reliability of the test results. The glove box can precisely meet this requirement. When conducting charge and discharge tests on solid-state batteries, moisture and oxygen in the environment may interfere with the charging and discharging process of the batteries. Moisture may trigger side reactions inside the battery, consuming the active substances of the battery and accelerating the capacity attenuation of the battery. Oxygen may undergo oxidation reactions with the electrode materials in the battery, affecting the performance of the electrodes and, in turn, the accuracy of the charge-discharge curve. Conducting charge and discharge tests in the glove box eliminates the interference of water and oxygen, which can truly reflect the charge and discharge performance of the battery. The obtained data is more accurate and reliable, providing a strong basis for the performance evaluation and optimization of the battery. When conducting battery cycle life tests, a stable environment is equally crucial. If the test environment is unstable, such as significant fluctuations in parameters like temperature and humidity, it will cause the battery to be affected to varying degrees in different cycle periods, resulting in deviations in the test results and making it impossible to accurately assess the actual cycle life of the battery.

3、How to choose a glove box

(1)Sealing property: Sealing property is one of the main performance characteristics of glove boxes. Good sealing performance can ensure the stability of the environment inside the glove box and prevent external air, moisture and impurities from entering. When choosing a glove box, you can evaluate its sealing performance by checking the product's sealing structure, sealing materials, and test reports, etc. Some glove boxes adopt O-ring vacuum sealing design, which can achieve a good sealing effect.

(2)Filtration system: The filtration system is also crucial to the performance of the glove box. It can remove dust, moisture and oxygen from the glove compartment, keeping the internal environment clean and pure. The efficiency and lifespan of the filtration system are the key indicators that need to be focused on. At the same time, it is necessary to understand the maintenance and replacement cycle of the filtration system so as to do a good job in maintenance and management during the usage process.

(3)Ease of operation: Ease of operation directly affects work efficiency and user experience. When choosing a glove box, it is necessary to consider whether the position and size of the operation port are appropriate and whether it is convenient for operation. Some glove boxes are also equipped with lighting systems, tool racks and other accessories, all of which can enhance the convenience of operation. In addition, the control system of the glove box should also be simple and easy to understand, easy to operate and adjust.

(4)When choosing a glove box, one should not merely focus on the price but comprehensively assess its cost-effectiveness. The cost of a glove box not only includes the one-time investment at the time of purchase, but also its usage cost cannot be ignored. Take the filtration system of a glove box as an example. The filter element, as a vulnerable part, its replacement frequency and cost directly affect the usage cost. A high-performance glove box may be relatively expensive in the initial stage, but due to its high filtration system efficiency and long service life, it can actually reduce the usage cost in the long run.

Meanwhile, the energy consumption during the operation of the glove box is also an important component of the usage cost. Although energy-saving glove boxes may be more expensive than ordinary ones, they can save costs in subsequent use through lower energy consumption. In addition, the service life and performance stability of the glove box are related to its cost performance. A reliable glove box not only provides a stable testing environment and ensures the accuracy of experimental data, but also further reduces the overall cost due to fewer faults and a lower maintenance rate. Only by comprehensively considering these factors can one select a glove box that meets the needs and has a high cost performance.

With the rapid development of technology, solid-state battery technology is constantly advancing, which also puts forward higher requirements for glove box technology. To meet the ultimate requirements of solid-state batteries for material purity and environmental purity, the glove box needs to continuously enhance its purification capacity, further reduce the water, oxygen content and impurity levels inside the box, and ensure that the battery materials are not contaminated in the slightest during the preparation and production process. More precise environmental control technologies are also of crucial importance. The future glove box not only needs to achieve a waterless and oxygen-free environment, but also be capable of precisely controlling various environmental parameters such as temperature, humidity and pressure to meet the special requirements of different solid-state battery materials and production processes.