In today's society, lithium batteries are everywhere, from our daily use of mobile phones, laptops, to electric vehicles, energy storage power stations and other large equipment, lithium batteries with its high energy density, long cycle life and low self-discharge rate advantages, has become the core of the modern energy storage field. However, to ensure the performance, safety and quality of lithium batteries, a key device - lithium battery tester.

1, the importance of lithium battery tester

Although lithium batteries have brought great convenience to our lives, there are also certain risks. Problems such as overcharge, overdischarge, overheating and internal short circuit will not only shorten the service life of the battery, reduce its performance, but also cause fire, explosion and other safety accidents in serious cases. As the "goalkeeper" to ensure the quality of lithium batteries, the lithium battery tester can detect potential problems in time by accurately measuring various parameters of the battery, and provide strong support for the research and development, production, use and maintenance of lithium batteries.

During the research and development phase, the lithium battery tester helps researchers gain insight into the performance and characteristics of the battery, so as to optimize the battery design and develop new batteries with better performance. In the production process, it strictly tests each piece of lithium battery to ensure that the quality of the factory battery is reliable. During use, the tester can help users grasp the status of the battery in time to avoid device damage or safety accidents caused by battery failure.

2, the type of lithium battery tester

(1) Protection board tester

Lithium battery protection board is an important part to prevent battery overcharge, overdischarge and overcurrent, and the protection board tester is a device specially used to test the performance of the protection board. This type of tester usually uses a capacitive analog load to test the functions of the protection board by simulating the charging and discharging process of the battery.

Taking a common protection board tester on the market as an example, its input power requirements are AC 220V±10%, 50Hz±2Hz, and rated power of 15VA. In terms of test parameters, the overcharge voltage test range is 0-5.0V, the overdischarge voltage test range is 1.5-5.0V, and the short-circuit protection response time is usually within 200ms. Some advanced protective board tester, such as the second generation HT3672, uses microcomputer control technology, the test speed is faster, only 3 seconds to complete the comprehensive test of the protective board. In addition, the tester also has the functions of independent test item control, internal resistance test and out-of-tolerance alarm, which greatly improves the accuracy and efficiency of the test.

Battery capacity is one of the important indicators to measure the performance of lithium batteries, and the battery capacity tester is a device used to accurately measure the battery capacity. For example, the capacity integrated machine developed by Jingshi Electromechanical of Huazi Technology can synchronously test multiple lithium batteries in the process of constant current and constant voltage charge and discharge. By monitoring the status of the battery in real time, the capacity of each battery is accurately calculated.

In addition to industrial-grade large-capacity testers, there are also small battery capacity testers for ordinary consumers on the market, such as four-channel 18650 lithium battery capacity testers. This tester enables individual users to test the capacity and internal resistance of the 18650 lithium battery. However, in the process of use, it should be noted that the battery needs to be completely discharged before the capacity test, and the internal resistance measurement results of the tester may be biased.

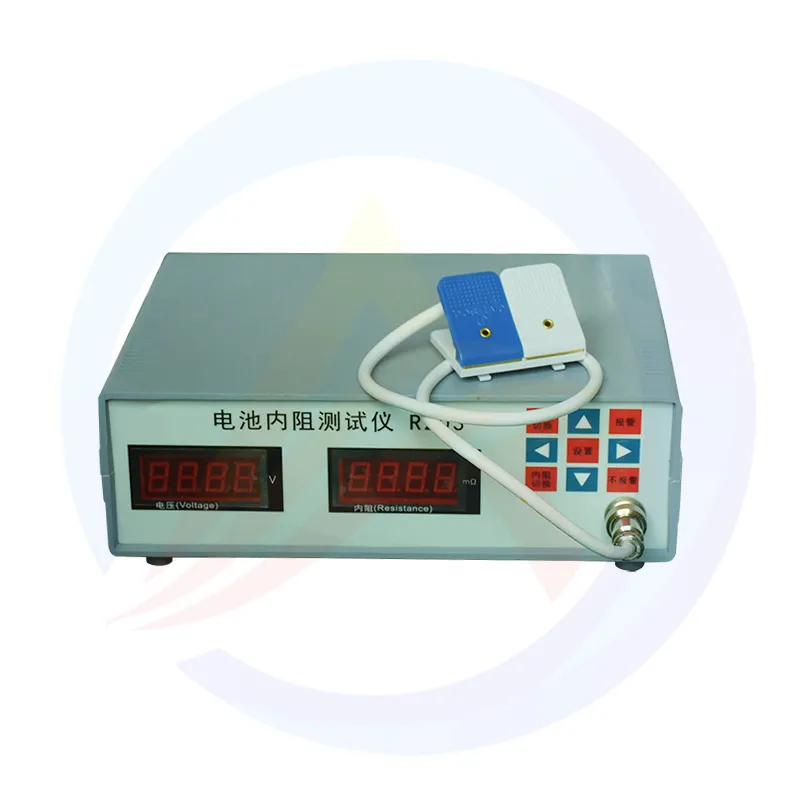

(3) battery internal resistance tester

The battery internal resistance tester of lithium battery is the key parameter to reflect its performance, which directly affects the discharge efficiency, temperature rise and service life of the battery. At present, there are two kinds of battery internal resistance tester methods: DC battery internal resistance tester method and AC internal resistance testing method.

The DC battery internal resistance tester method is to measure the voltage drop at both ends of the battery by passing a large constant DC current (generally 40A-80A) to the battery for 2-3 seconds, so as to calculate the battery internal resistance tester of the battery. However, this method will cause polarization of the battery electrode and affect the accuracy of the test results.

The test principle of AC battery internal resistance tester is to inject a sinusoidal AC current signal into the battery, and calculate the AC battery internal resistance tester of the battery by measuring the sinusoidal AC voltage signal at both ends of the battery. The method uses a small current (generally about 50mA) and a short test time (milliseconds), which can effectively avoid the influence of electrode polarization on the test results. Taking Chutian Electronics SBT300 battery tester as an example, it adopts AC four-terminal test method, resistance resolution up to 0.1μΩ, voltage resolution up to 10μV. The tester also has a comparator function, can be qualified to judge, and can output analog signals, convenient for users to long-term data recording and statistical analysis, but also can draw the normal distribution map.

3, the working principle of lithium battery tester

(1) Simulate the working state of the battery

Most lithium battery testers test the battery by simulating the charging, discharging and resting state of the battery in actual use. For example, the protection board tester detects the performance of the protection board by simulating the charging and discharging process of the battery through capacitance, triggering the protection function of the protection board.

(2) Sensor parameter detection

The tester is equipped with a variety of high-precision sensors for real-time detection of battery voltage, current, temperature and internal resistance parameters. These sensors are able to convert physical quantities into electrical signals and transmit them to the tester's control system for processing. Taking the voltage sensor as an example, its measurement accuracy can reach 1mV, which can accurately capture small changes in battery voltage.

(3) Data analysis and report generation

After collecting a large amount of test data, the tester will analyze and process the data. Some advanced testers also have statistical analysis functions that can calculate statistical parameters such as the mean, maximum, minimum and standard difference of the data. In addition, the tester can also generate a detailed test report, present the test results in the form of charts or text, so that users can intuitively understand the performance of the battery.

4. Application scenario of lithium battery tester

(1) Lithium battery manufacturing

In the lithium battery production line, the lithium battery tester is an indispensable equipment. It is able to conduct a comprehensive inspection of every battery in the production process, and timely detect unqualified products to avoid their flow into the market. For example, the capacity tester and the internal resistance tester can quickly screen out batteries with insufficient capacity or excessive internal resistance, and the protection board tester can ensure the normal function of the protection board. By using lithium battery testers, manufacturers can improve product quality, reduce production costs, and enhance market competitiveness.

(2) Lithium battery research and development

In the development process of lithium batteries, researchers need to deeply understand the performance and characteristics of batteries in order to develop more advanced battery technology. Lithium battery testers provide researchers with accurate test data to help them analyze the battery's charge-discharge behavior, cycle life, energy efficiency and other performance indicators, so as to optimize the design and manufacturing process of the battery.

5, lithium battery tester industry development trend

(1) The demand for high-precision testing increases

With the continuous expansion of the application field of lithium batteries, the performance requirements of lithium batteries are becoming higher and higher. This requires higher precision and resolution for lithium battery testers to meet increasingly stringent testing standards. For example, Hantai's HBT4000 series battery internal resistance tester uses 6 1/2 bit resolution, resistance resolution up to 0.1μΩ, voltage resolution up to 1μV, greatly improving the accuracy of the test.

(2) Integration of intelligent technology

Artificial intelligence, Internet of things and other intelligent technologies are more and more widely used in lithium battery testers. Artificial intelligence technology can analyze and mine a large amount of test data, predict battery performance and life, and detect potential problems in advance. The Internet of Things technology enables the tester to achieve remote monitoring and data transmission, and users can view the test results anytime and anywhere through mobile phones or computers to achieve intelligent management.