In the manufacturing process of lithium batteries, the uniform mixing of materials is a key step to ensure stable battery performance and extended life. The Planetary Vacuum Mixer Machine, as an efficient and precise mixing device, is gradually becoming an indispensable tool in the manufacture of lithium battery materials.

1、What is a Planetary Vacuum Mixer Machine?

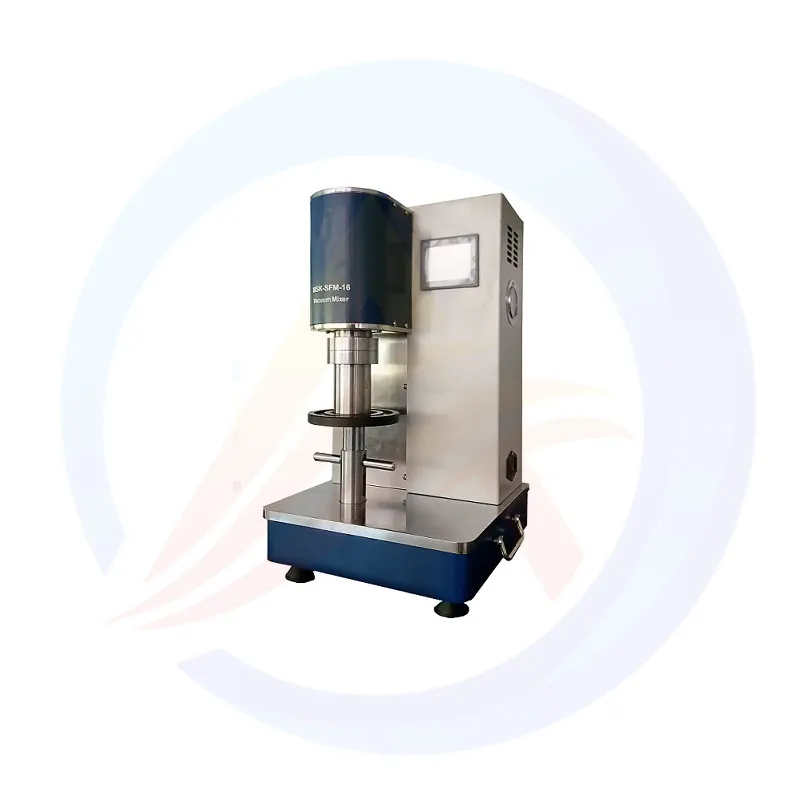

The Planetary Vacuum Mixer Machine is a mixing device that combines planetary stirring and vacuum technology. Through the rotation and revolution of the planetary stirring arm, it ensures that the material is evenly mixed in a vacuum environment, avoiding the generation of bubbles and impurities. This kind of equipment is widely used in the mixing process of lithium battery anode and cathode materials, electrolyte, adhesive and other materials.

2、the use of Planetary Vacuum Mixer Machine in the manufacture of lithium batteries

(1) Uniform mixing of positive and negative electrode materials

The positive and negative electrode materials of lithium batteries are usually composed of active substances, conductive agents and adhesives. The uniform mixing of these materials directly affects the electrochemical performance and cycle life of the battery. The Vacuum Mixer Machine, with its unique planetary stirring method, is able to blend materials evenly in a short time, ensuring the same quality of materials from batch to batch.

(2) Remove bubbles and improve material density

In the manufacturing process of lithium batteries, bubbles in the material can cause the internal structure of the battery to be uneven, which affects the performance and safety of the battery. The Planetary Vacuum Mixer Machine works in a vacuum environment to effectively remove bubbles from the material and improve the density and consistency of the material.

(3) Suitable for the mixing of high-viscosity materials

The adhesives and electrolytes used in the manufacture of lithium batteries usually have high viscosity, and it is difficult to achieve uniform mixing with traditional mixing equipment. The Planetary Vacuum Mixer Machine can easily handle high viscosity materials through its powerful stirring capacity and vacuum environment to ensure mixing results.

(4) Improve production efficiency

The Planetary Vacuum Mixer Machine has an efficient mixing capability that can mix large quantities of materials in a short period of time. This not only improves production efficiency, but also reduces energy consumption and labor costs.

3、Core advantages of Planetary Vacuum Mixer Machine

(1) Efficient mixing effect

The rotational and rotational motion of the planetary stirring arm ensures that the material is evenly mixed in three-dimensional space, avoiding the dead Angle problem common in conventional stirring equipment.

(2) bubble-free mixing under vacuum environment

The vacuum environment not only removes the bubbles in the material, but also prevents the oxidation reaction of the material in contact with the air during the mixing process, further improving the quality of the material.

(3) Versatility

The Planetary Vacuum Mixer Machine is not only suitable for the mixing of lithium battery materials, but also for the mixing of other high-precision materials, such as ceramics, coatings, pharmaceuticals, etc.

(4) Automatic control

Modern Planetary Vacuum Mixer machines are usually equipped with advanced automated control systems that allow users to easily set mixing parameters via a touch screen or computer for precise control.

4、how to choose a suitable Planetary Vacuum Mixer Machine?

(1) Select according to material characteristics

Different lithium battery materials have different requirements for mixing equipment. For example, high-viscosity materials require a stronger stirring capacity, while easily oxidized materials require better vacuum sealing properties. Therefore, when selecting equipment, it should be selected according to the characteristics of the material.

(2) Consider the scale of production

For large-scale lithium battery manufacturers, choosing a Planetary Vacuum Mixer Machine with large capacity and high degree of automation can significantly improve production efficiency. For small-scale or laboratory environments, you can choose a small, flexible model.

(3) Pay attention to the durability and maintenance cost of the equipment

As a high-precision equipment, the durability and maintenance cost of the Planetary Vacuum Mixer Machine directly affect the long-term use effect. Choosing well-known brands and reliable quality equipment can reduce failure rates and maintenance costs.

5、the future development trend of Planetary Vacuum Mixer Machine

With the continuous progress of lithium battery technology, the requirements for material mixing equipment are becoming higher and higher. In the future, the Planetary Vacuum Mixer Machine will develop in the following directions:

(1) Higher degree of automation

Through the introduction of artificial intelligence and iot technology, the Planetary Vacuum Mixer Machine will enable smarter operation and monitoring, further improving production efficiency and product quality.

(2) More environmentally friendly design

With the increasing awareness of environmental protection, the future Planetary Vacuum Mixer Machine will pay more attention to energy saving and environmentally friendly design, reducing energy consumption and waste emissions.

(3) A wider range of applications

In addition to lithium battery manufacturing, Planetary Vacuum Mixer Machine will also be widely used in other high-precision material mixing fields, such as new energy materials, nanomaterials and so on.

conclusion

As a key device in the manufacture of lithium batteries, the Planetary Vacuum Mixer Machine's efficient mixing capacity, bubble-free mixing in vacuum environment and versatility make it an important tool to improve the quality and production efficiency of lithium batteries. With the continuous development of lithium battery technology, the application prospect of Planetary Vacuum Mixer Machine will be broader.