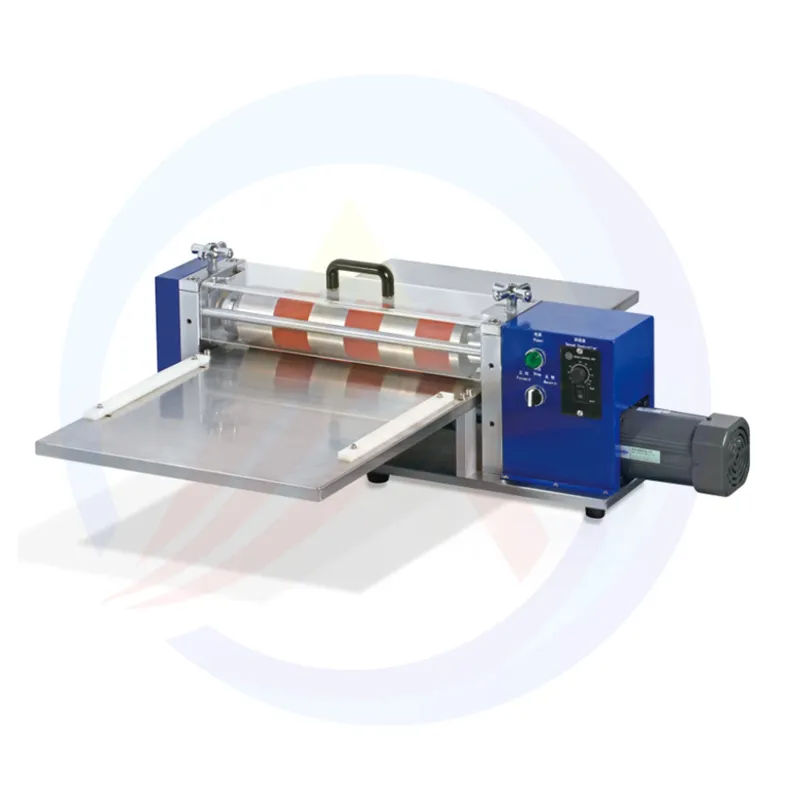

1、lithium battery electrode cutting machine overview

The lithium battery electrode slitting machine is one of the key equipment in the lithium battery production line. It is mainly used to accurately slitting the coated positive and negative electrode pieces according to the specific width requirements, and separately winding and collecting. It usually adopts advanced control systems and precise mechanical structures to ensure that each cutting can achieve extremely high accuracy requirements to meet the high standards of pole piece size and shape in lithium battery production. Through the high-precision cutting of the pole slicer, the pole slicer of the lithium battery can be accurately cut according to the preset size and shape, so as to meet the performance requirements and production efficiency requirements of the lithium battery.

2、the core characteristics of lithium battery electrode slitting machine

(1) High precision

The lithium battery slitting machine adopts advanced cutting technology and control system to ensure that the cutting accuracy meets the preset requirements, so as to improve the performance and stability of lithium batteries. Its cutting accuracy can usually be controlled in the micron level, which is crucial to ensure the consistency of the lithium battery pole sheet size and improve the efficiency and performance of battery assembly. With precise cutting, the gap between the polar slices can be reduced and the energy density and cycle life of the battery can be improved.

(2) High efficiency

By optimizing the cutting path and speed control, the lithium battery electrode slitting machine can complete the cutting of a large number of electrodes in a short time, and significantly improve the production efficiency of lithium battery. Efficient cutting capabilities mean faster production cycles and lower costs, which are essential to meet the rapidly growing market demand for lithium batteries. At the same time, the introduction of automated production lines further improves production efficiency, reduces manual intervention, and reduces production costs.

(3) High stability

The lithium battery slitting machine is designed with full consideration of stability and durability, which can work continuously for a long time to ensure the stable operation of the lithium battery production line. Stable performance means less breakdowns and downtime, which is essential to maintain continuity of the production line and improve the overall production efficiency. At the same time, the high stability of the equipment also reduces maintenance costs and prolongs the service life of the equipment.

(4) Easy to operate and maintain

Lithium battery electrode slitting machine usually adopts humanized operation interface and intelligent maintenance system, which makes the operation and maintenance become simple and convenient. The intuitive operation interface and the convenience of intelligent maintenance system reduce the training cost and maintenance difficulty of operators, and improve the overall operation efficiency of the production line.

(5) High flexibility

The lithium battery slitting machine is usually equipped with a variety of cutting methods and tools, which can adapt to the cutting needs of different thicknesses and materials. This flexibility allows the device to be applied to many types of lithium battery production, including small consumer electronics, electric vehicles, energy storage systems, and other fields.

3、Influence of lithium battery electrode slitting machine on lithium battery manufacturing

(1) Improve battery performance

The high-precision cutting of the lithium battery slitter ensures the consistency of the electrode size and reduces the gap between the electrode pieces, thereby improving the energy density and cycle life of the battery. At the same time, the precise cutting also reduces the burr and stress concentration at the edge of the pole piece, which improves the safety and stability of the battery. These performance improvements make lithium batteries more widely and reliably used in electric vehicles, energy storage systems and other fields.

(2) Improve production efficiency

The efficient cutting ability of the lithium battery slitting machine and the introduction of automated production lines have significantly improved the production efficiency of lithium batteries. Fast cutting speed and reduced manual intervention lead to shorter production cycles and lower costs. This is crucial to meet the rapidly growing market demand for lithium batteries, and also provides a stronger market competitiveness for lithium battery manufacturers.

(3) Reduce production costs

The characteristics of high stability and easy operation and maintenance of lithium battery slitting machine reduce the production cost. Stable performance reduces failures and downtime and reduces maintenance costs. At the same time, the humanized operation interface and intelligent maintenance system reduce the training cost and maintenance difficulty of operators. These cost reductions enable lithium battery manufacturers to pay more attention to product quality improvement and technological innovation, thereby promoting the sustainable development of the entire industry.

(4) Promoting technological innovation

With the rapid development of new energy industry and the continuous progress of technology, lithium battery electrode cutting machine is also constantly upgrading and improving. New cutting techniques and material handling techniques are constantly introduced to improve cutting speed and accuracy and reduce energy consumption and emissions. These technological innovations not only promote the development of lithium battery electrode slitting machine, but also bring more opportunities and challenges for the entire lithium battery manufacturing industry.

4、Market application and future trend of lithium battery electrode slitting machine

(1) Market application

The lithium battery slitting machine is widely used in the lithium battery manufacturing industry, including small consumer electronics, electric vehicles, energy storage systems and other fields. With the rapid growth of the electric vehicle market and the wide application of energy storage systems, the market demand for lithium battery electrode slitting machines is also increasing.

(2) Future trends

In the future, the lithium battery slitting machine will pay more attention to the development direction of intelligence, automation and environmental protection. By introducing advanced control technology and sensor technology, intelligent control and remote monitoring of equipment are realized. This will further improve the automation level and production efficiency of the equipment and reduce manual intervention and error.

The intelligent upgrade will make the lithium battery electrode slitting machine better adapt to the changing market demand and production environment. Through big data analysis and machine learning technology, the equipment can automatically adjust cutting parameters and process routes to optimize production efficiency and product quality. At the same time, the remote monitoring and fault diagnosis function will make the maintenance and management of equipment more convenient and efficient.

The improvement of automation will make the lithium battery electrode slitter can better meet the needs of mass production. By introducing technologies such as robots and automated production lines, the whole process of automatic production from material cutting, feeding, cutting to receiving can be realized. This will further improve production efficiency, reduce production costs, and improve product quality and consistency.

5、Conclusion

As one of the key equipment in the lithium battery manufacturing process, the lithium battery electrode slitting machine plays an important role in the lithium battery production line due to its high precision, high efficiency, high stability and easy operation and maintenance. Through continuous technological innovation and application expansion, lithium battery electrode slitting machine will continue to make an important contribution to the development of lithium battery industry. At the same time, we should also pay attention to the future development trend of lithium battery electrode cutting machine, in order to adapt to the changing market demand and promote the sustainable development of lithium battery production.