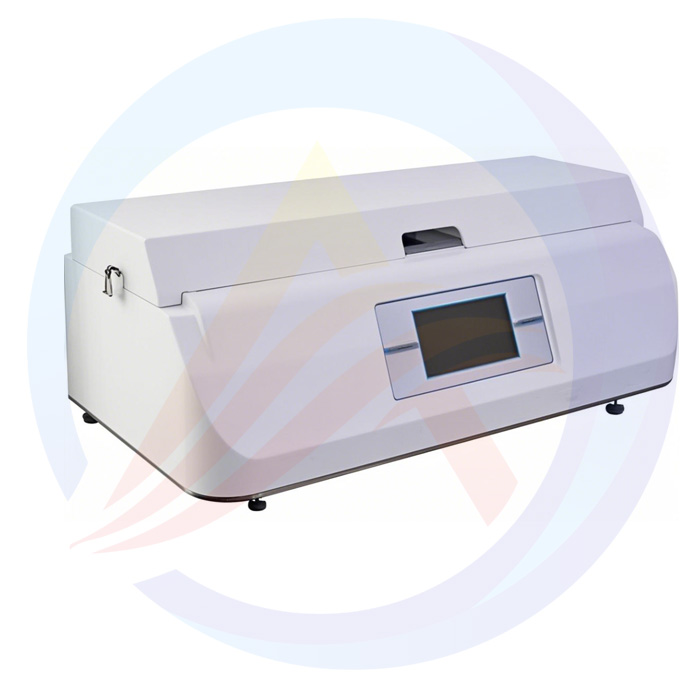

AOT-MSK-TE602-PS is lab-scale peel strength tester for battery electrodes or other thin-films. It equips a temperature control unit to enable testing under different temperatures.

Product Model | AOT-MSK-TE602-PS |

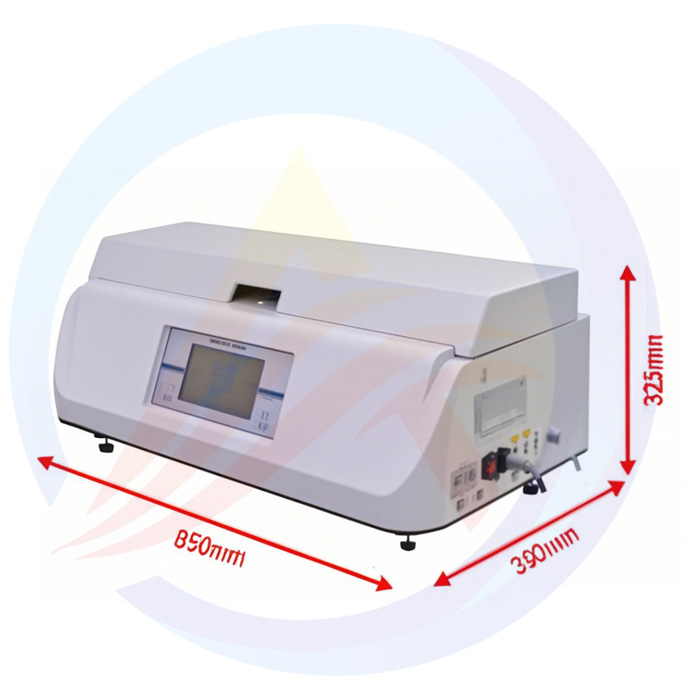

Power Requirement | AC220V ±10%, 50Hz/60Hz, single phase 200W |

Test Mode | Coefficient of Friction Test Peel Strength Test |

Loading Range | 0-5 N 0-10 N 0-30 N |

Accuracy | 0.5 class |

Sliding Block Mass | Standard block with 200 g (other mass of 100 g, 500 g, 1000 g, 1814 g, and 2000 g are available upon request ) |

Testing Speed | 1-600 mm/min |

Testing Temperature | RT-99.9 ℃ |

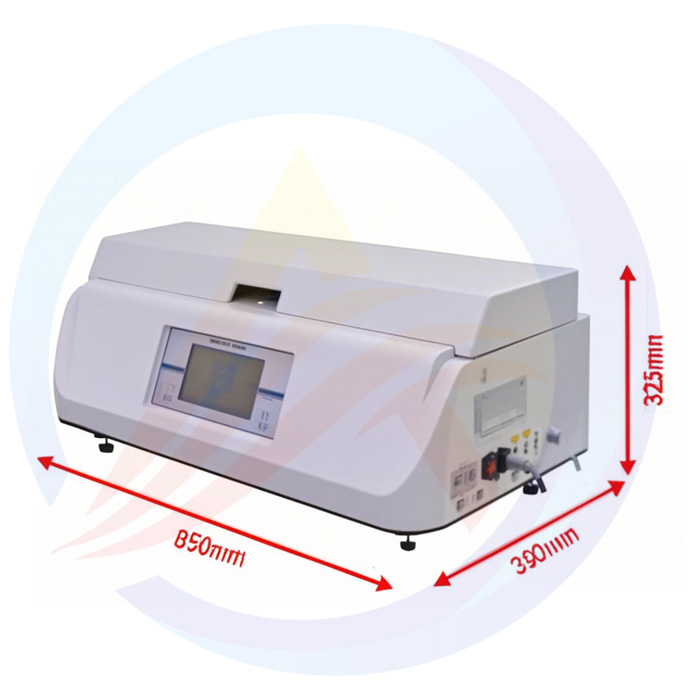

Product Dimensions | 850mm x 390mm x 325mm (L x W x H) |

Weight | 33kg |

Company Profile

Xiamen AOT battery equipment Technology Co LTD was set up as a manufacturer in 2006. We have total manufacturing facilities of around 4, 000 square meters and more than 65 staff. Owning a group of experienced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy. AOT Battery has been focused on product development and operations of lithium battery and its surrounding, we supply full kinds of lithium-ion battery equipment, lab battery raw materials and lithium-ion battery research and development technology.

Exhibition

AOT Lithium Battery Equipment exhibition provides exhibitors and visitors with a comprehensive platform for display, exchange, cooperation and trade. By participating in the exhibition, enterprises can understand the industry dynamics, expand market channels, enhance brand image and promote technological innovation and industrial upgrading.

Certificate

Cooperative

Q. What is Battery Electrodes Peel Strength Tester ?

A. The battery electrode peel strength tester is a device used to detect the adhesion force between active materials (such as lithium cobalt oxide) and current collectors (such as aluminum foil and copper foil) in lithium-ion battery electrodes. By controlling the speed and Angle of sample stripping, measuring the required force value, and evaluating the quality of electrode bonding, the cycle life and safety of batteries are ensured. This is commonly seen in production quality control and material research and development.

Q. The function of the Battery Electrodes Peel Strength Tester

The Battery Electrodes Peel Strength Tester is used to measure the adhesion force between the active material of the battery electrode and the current collector. The electrode bonding strength can be evaluated to prevent detachment and delamination, ensure the structural stability of the battery during cycling, reduce capacity attenuation and short-circuit risk, and enhance lifespan and safety. It is applicable to production quality control (coating process, binder selection) and material research and development to optimize electrode performance.

Q. What should be noted when using a battery electrode tester

1.Environmental adaptation: Select a dry, well-ventilated site free from strong electromagnetic interference for operation to ensure that the measurement accuracy of the battery electrode tester is not affected by external factors.

2.Equipment pre-inspection: Before starting up, check whether the electrode connection of the battery electrode tester is stable and whether the cables are damaged, and complete the instrument calibration.

3.Safety precautions: Wear insulating gloves during testing to avoid direct contact with the electrodes of the battery electrode tester, preventing the risk of electric shock or short circuit.

4.Standard operation: During the test, read the data according to the procedure and record it in a timely manner. After the test, turn off the power, clean the instrument electrodes and store them properly.

Q.How to choose a Battery Electrodes Peel Strength Tester

When choosing a battery electrode tester, it is necessary to first clarify the testing requirements, such as being compatible with two types of electrodes or different voltage ranges. At this point, the accuracy (resolution, error value) and stability of the two battery electrode testers can be compared. Consider whether the number of channels is sufficient for batch testing, observe the interface compatibility of the two (such as whether they can be adapted to different electrode fixtures), and then compare the convenience of the operation interface and data storage functions. Give priority to choosing a battery electrode tester with a good brand reputation and complete after-sales service.