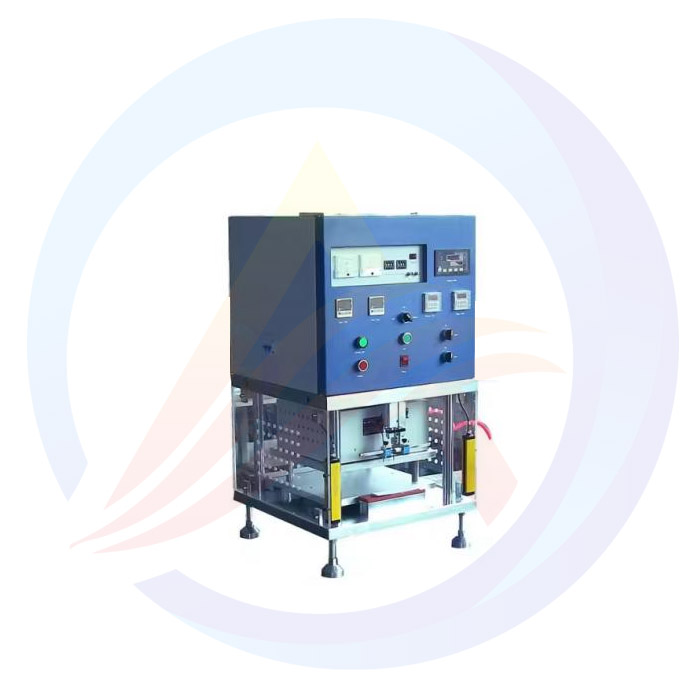

MSK-TE910 Battery Short Circuit Test System allows for testing pouch cell or its battery pack with adjustable temperature and pressure. Such a system has two test methods which are auto-mode and manual-mode. What's more, this machine tests insulation resistance precisely to recognize the micro circuit status of the battery in order to test the safety issue of the battery.

Product Model | AOT-MSK-TE910 |

Features | Adjustable temperature control Adjustable pressure control |

Working Voltage | AC220V±10% 50/60Hz |

Working Pressure | 0~900Kg ±3Kg |

Working Distance | 0-80mm |

Working Temperature | Upper and Lower Platen:130ºC±5ºC Max. |

Pouch Battery Size | 300 x 300 x 70mm Max. |

Short Circuit | Auto alarm |

Testing nput Voltage | DC 0~500V adjustable |

Max. Mesurable Leakage Current | 50 uA |

Resistivity Measurement Range | Max. 199MΩ |

Testing Period | 0~99 Seconds adjustable (2~3 seconds is suggested) |

Product Dimensions | 500mm x 500mm x 1025mm (L x W x H) |

Weight | 220kg |

Company Profile

Xiamen AOT battery equipment Technology Co LTD was set up as a manufacturer in 2006. We have total manufacturing facilities of around 4, 000 square meters and more than 65 staff. Owning a group of experienced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy. AOT Battery has been focused on product development and operations of lithium battery and its surrounding, we supply full kinds of lithium-ion battery equipment, lab battery raw materials and lithium-ion battery research and development technology.

Exhibition

AOT Lithium Battery Equipment exhibition provides exhibitors and visitors with a comprehensive platform for display, exchange, cooperation and trade. By participating in the exhibition, enterprises can understand the industry dynamics, expand market channels, enhance brand image and promote technological innovation and industrial upgrading.

Certificate

Cooperative

FAQ

Q. What is battery short circuit test system?

A. The battery short-circuit testing system is a device used to simulate battery short-circuit conditions and test the safety performance of batteries. It precisely controls the short-circuit conditions, monitors the changes in parameters such as voltage, current and temperature of the battery during a short circuit, assesses the battery's short-circuit resistance and safety, and ensures the battery's reliability in extreme situations. It is widely used in battery research and development, production and testing, and other fields.

Q. The role of battery short circuit test

A. Battery short circuit test simulate extreme short-circuit scenarios to monitor changes in battery parameters such as voltage, current, and temperature. This can verify the stability of the battery's internal structure and the effectiveness of safety protection designs, and expose potential thermal runaway and fire hazards that may occur in the battery under short-circuit conditions in advance. It provides key data support for battery research and development optimization, production quality control, and the formulation of safety standards. Ensure the safety of battery applications.

Q. How to choose a battery short circuit test machine?

When choosing a battery short circuit test machine, it is necessary to consider the measurement range (voltage/current matching), accuracy (μ S-level triggering, mΩ -level resistance), functions (multi-mode short-circuit, safety protection), compliance (national standards/international standards), and the manufacturer's services to ensure the accuracy and reliability of the test.