1.Parameters of the two-position tank grinder

Model | AS-GQM-2-5 | AS-GQM-2-15 | AS-GQM-2-20 |

Overall Dimensions/Weight | 950X480X685/59KG | 1130X550X690/80KG | 1350X650X690/92KG |

Motor Model/Power | YE2-80M2-4B3 / 0.75KW | YE2-90S-4B3 / 1.1KW | YE2-90L-4B3 / 1.5KW |

Normal Power Supply | 220V, 50/60HZ | 220V, 50/60HZ | 220V, 50/60HZ |

Main Roller Speed (rpm) | 50 - 410±10 | 40 - 365±10 | 40 - 340±10 |

Hand Crank Device | Optional | Optional | Optional |

Protective Cover | Optional | Optional | Optional |

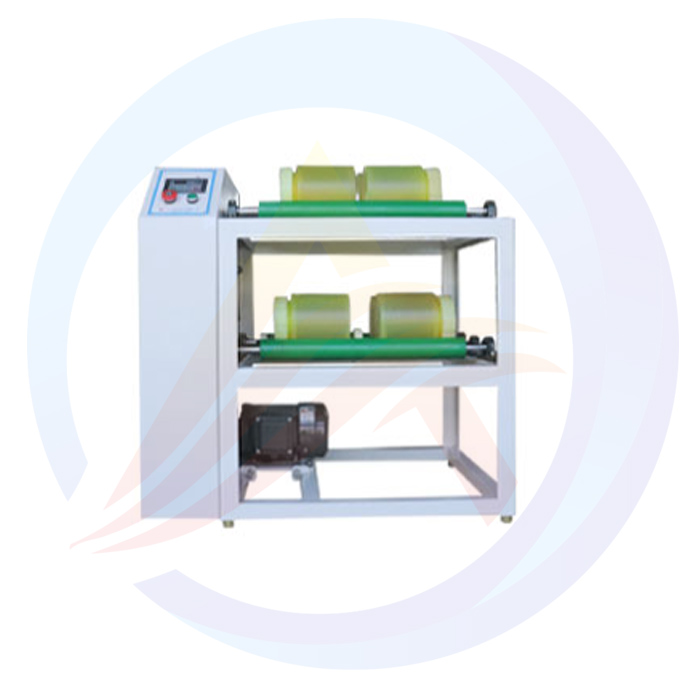

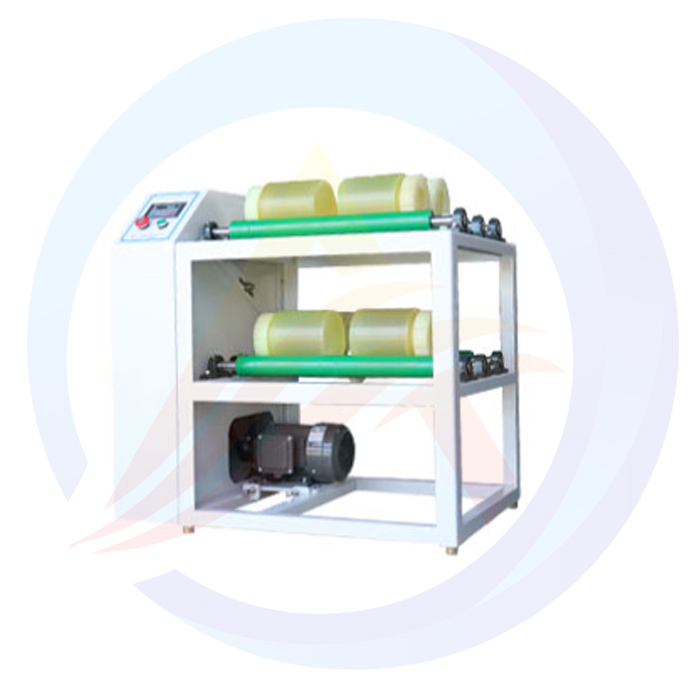

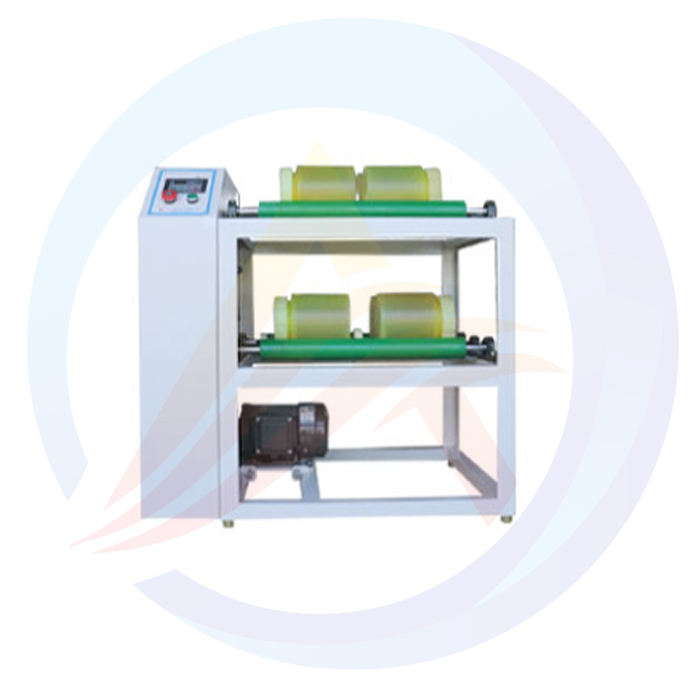

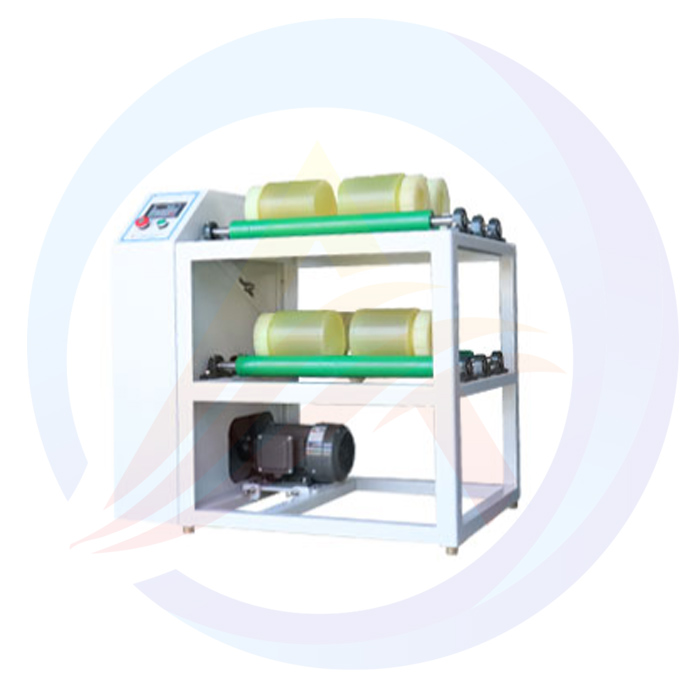

2.Parameters of the four-position drum grinder

Model | AS-GQM-4-5 | AS-GQM-4-5 (Double - layer) | AS-GQM-4-15 | AS-GQM-4-20 |

Overall Dimensions/Weight | 950X660X690/70KG | 950X480X870/(92KG) | 1130X800X690/95KG | 1350X820X690/122KG |

Motor Model/Power | YE2-80M2-4B3 / 0.75KW | YE2-80M2-4B3 / 0.75KW | YE2-90L-4B3 / 1.5KW | YE2-100L1-4B3 / 2.2KW |

Normal Power Supply | 220V, 50/60HZ | 220V, 50/60HZ | 220V, 50/60HZ | 380V, 50/60HZ |

Main Roller Speed (rpm) | 50 - 410±10 | 50 - 410±10 | 40 - 365±10 | 40 - 340±10 |

Hand - operated Device | Optional | Optional | Optional | Optional |

Protective Cover | Optional | Optional | Optional | Optional |

3.Parameters of the eight-position drum grinder

Model | AS-GQM-8-5 | AS-GQM-8-15 |

Overall Dimensions/Weight | 950X660X960/106KG | 1130X800X960/152KG |

Motor Model/Power | YE2-90L-4B3 / 1.5KW | YE2-100L1-4B3 / 2.2KW |

Normal Power Supply | 220V, 50/60HZ | 380V, 50/60HZ |

Main Roller Speed (rpm) | 50 - 410±10 | 40 - 365±10 |

Hand - operated Device | Optional | / |

Protective Cover | Optional | / |

Company Profile

Xiamen AOT battery equipment Technology Co LTD was set up as a manufacturer in 2006. We have total manufacturing facilities of around 4, 000 square meters and more than 65 staff. Owning a group of experienced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy. AOT Battery has been focused on product development and operations of lithium battery and its surrounding, we supply full kinds of lithium-ion battery equipment, lab battery raw materials and lithium-ion battery research and development technology.

Exhibition

AOT Lithium Battery Equipment exhibition provides exhibitors and visitors with a comprehensive platform for display, exchange, cooperation and trade. By participating in the exhibition, enterprises can understand the industry dynamics, expand market channels, enhance brand image and promote technological innovation and industrial upgrading.

Certificate

Cooperative

FAQ

Q.What is drum ball mill?

A.In the battery field, drum ball mill are mainly used for the preparation of battery materials. They can evenly mix and refine lithium - ion battery anode and cathode materials, such as LiFePO₄ and graphite, and are also applicable to the preparation of solid - state electrolyte materials, which helps improve battery performance.

Q.The function of the drum ball mill

A.In the field of batteries, the drum ball mill is mainly used for the preparation and processing of electrode materials. Through the impact and grinding action of the grinding media, it can finely reduce the raw materials such as positive electrodes (such as lithium iron phosphate) and negative electrodes (such as graphite) to the micron or nanometer level. At the same time, it achieves uniform mixing of the materials, enhancing the reactivity and consistency of the materials, thereby optimizing the energy density, cycle life and charging-discharging performance of the batteries. It is a key equipment in the production of battery materials.

Q.How to choose a Drum Ball Mill

When choosing a drum ball mill, factor in material hardness—pick a drum ball mill with wear-resistant linings for hard materials. For desired fineness, select a drum ball mill with suitable media size and speed. Match drum ball mill capacity to production needs. Opt for a drum ball mill with proper media (steel/ceramic) and easy maintenance. For batteries, prioritize a drum ball mill with non-polluting linings.