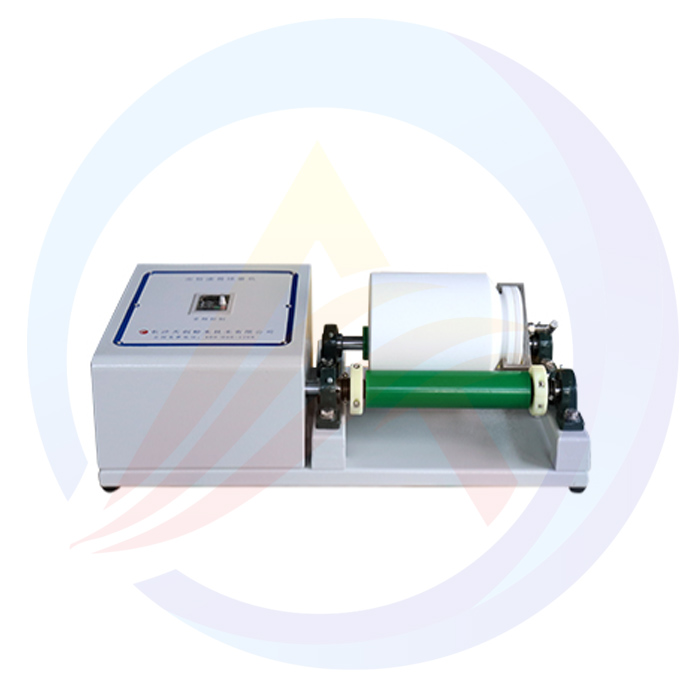

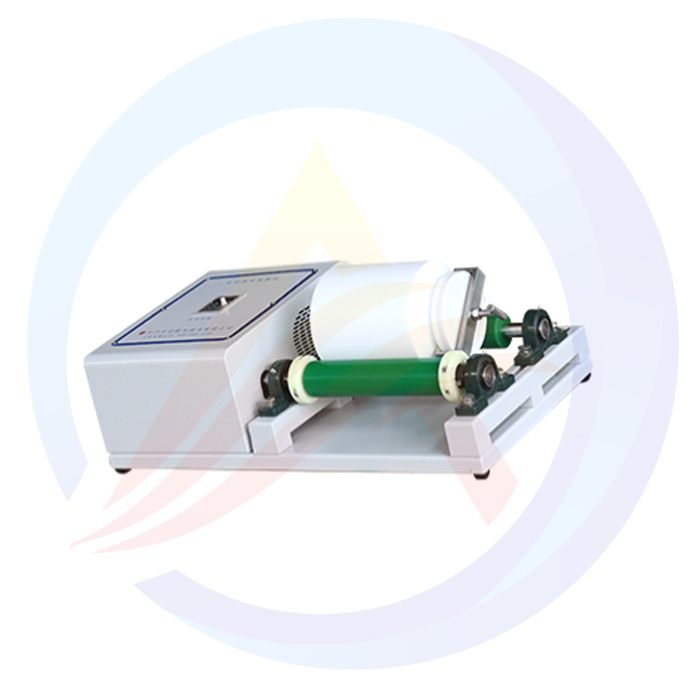

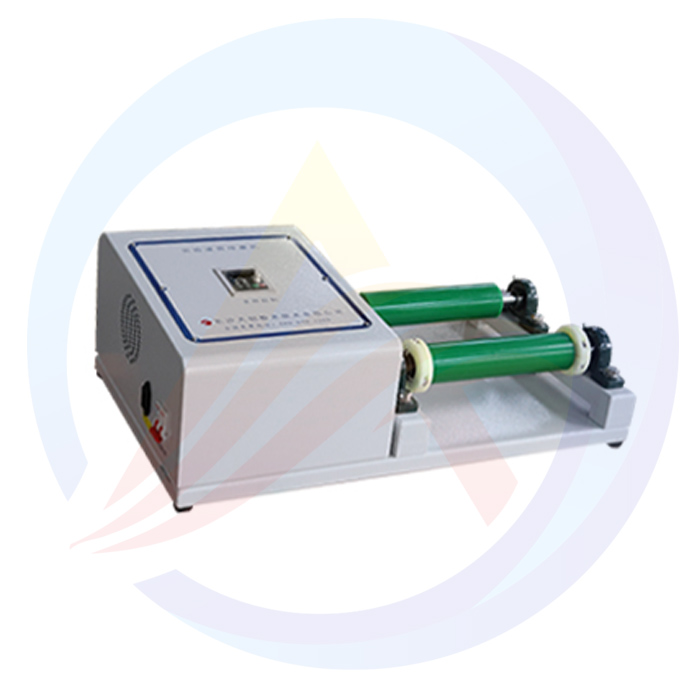

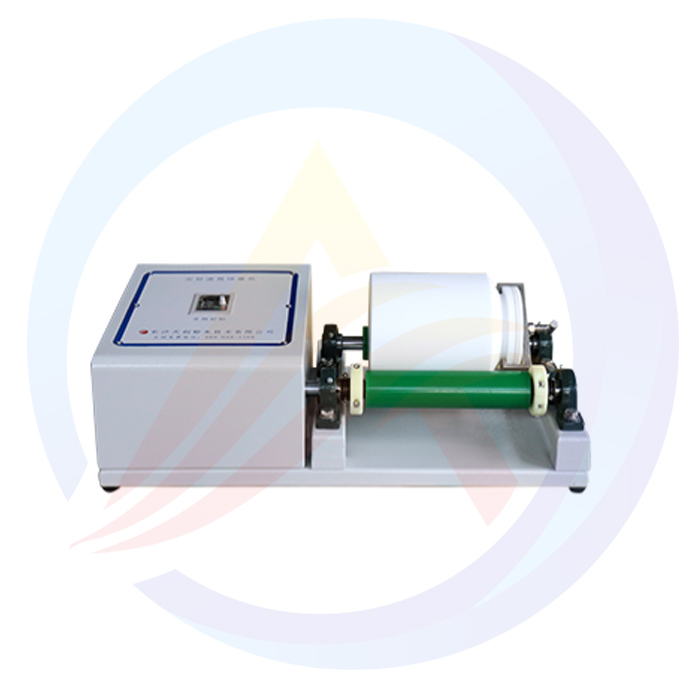

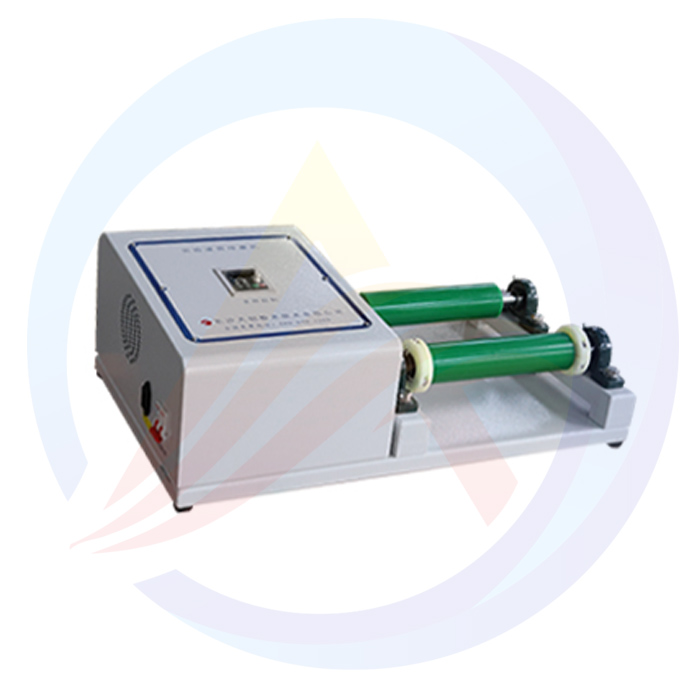

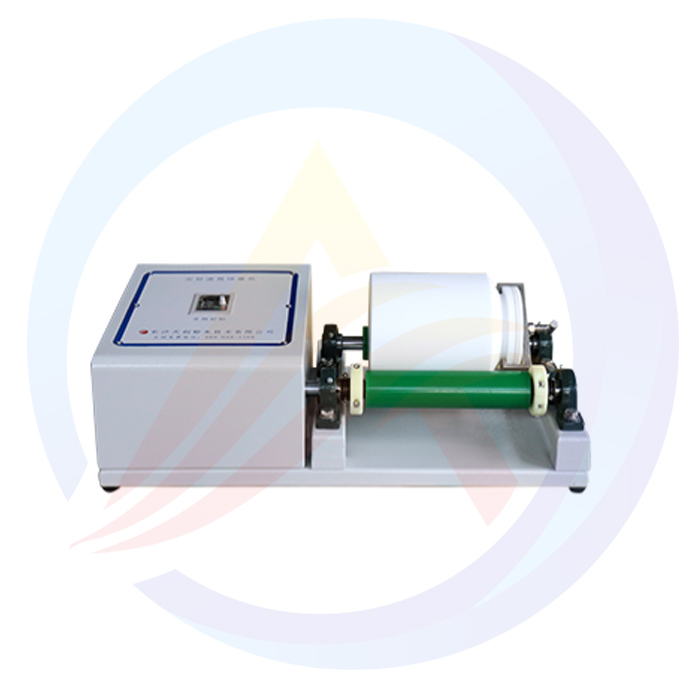

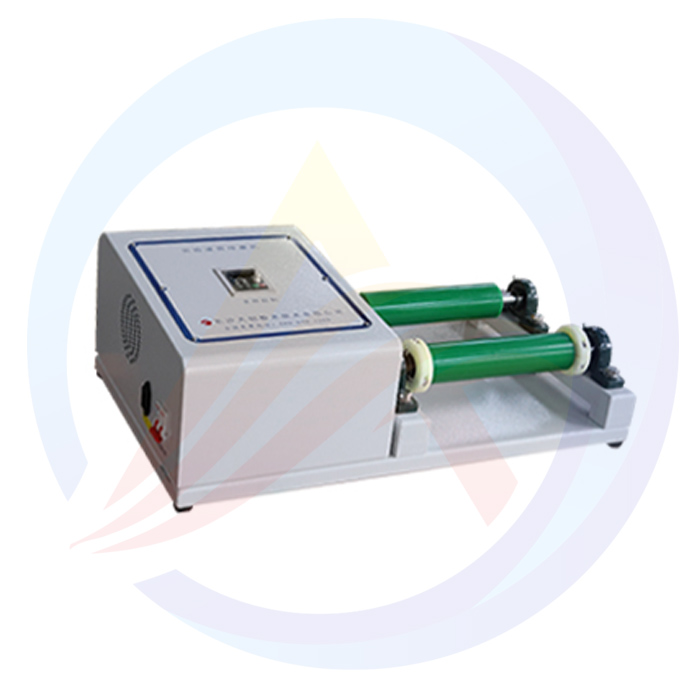

Lab Roll Jar Mill/Lab Roll Ball Mill Introduction

When the laboratory drum ball mill is working, the grinding medium and materials inside the cylinder are lifted to a certain height by the rotation of the cylinder. Due to the effect of gravity, they detach from the cylinder wall and fall along a parabolic line. The materials are crushed under the impact of the grinding medium and the friction and shear caused by the rolling and sliding of the grinding medium.

Features

1. Easy to maintain, compact structure, easy operation

2. High efficiency and uniform granularity

3. Milling pot in different size can be put on the driven rubber roller within a certain range by means of adjusting space between the rubber rollers.

4. It is convenient to change pots and suitable for both wet and dry grinding.

Applications

Roll ball Mill is mainly applied to industries of electronic material, magnetic material, biological medicine, ceramic glaze, metal powder, nonmetallic minerals, new materials,and etc.

Model | AOT-QM - 5L | AOT-QM - 15L |

Dimensions / Weight | 730X415X260/32KG | 845x435x270/43KG |

Motor model / Power | YS7124 - 4B3/0.37KW | YS8024 - 4B3/0.75KW |

Conventional power supply | 220V、50/60HZ | 220V、50/60HZ |

Main roller rotational speed (rpm) | 60~570±10 | 60~570±10 |

Company Profile

Xiamen AOT battery equipment Technology Co LTD was set up as a manufacturer in 2006. We have total manufacturing facilities of around 4, 000 square meters and more than 65 staff. Owning a group of experienced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy. AOT Battery has been focused on product development and operations of lithium battery and its surrounding, we supply full kinds of lithium-ion battery equipment, lab battery raw materials and lithium-ion battery research and development technology.

Exhibition

AOT Lithium Battery Equipment exhibition provides exhibitors and visitors with a comprehensive platform for display, exchange, cooperation and trade. By participating in the exhibition, enterprises can understand the industry dynamics, expand market channels, enhance brand image and promote technological innovation and industrial upgrading.

Certificate

Cooperative

FAQ

1. What is Roll ball mill?

A roll ball mill is a grinding device combining rolling and ball milling. It uses rotating rolls and grinding balls to crush materials. Materials are squeezed by rolls and impacted/abraded by balls between rolls, achieving fine grinding. Widely used in mineral processing, ceramics, and chemical industries for grinding brittle materials efficiently.

2.The role of battery Roll ball mill

The battery roll ball mill grinds active materials (e.g., lithium iron phosphate), conductive agents, and binders into ultra-fine, uniform powders/slurries. This boosts material surface area, enhances electrochemical reactivity, and ensures even electrode distribution, improving battery capacity, cycle life, and efficiency, while enabling precise particle control for subsequent production steps.

3.How to select a roll ball mill

When choosing a Roll ball mill, factors such as the material properties (hardness, particle size), production capacity requirements, and grinding fineness specifications should be considered. Pay attention to the equipment power, the material of the drum (wear-resistant and corrosion-resistant), the ratio of ball diameters, and also ensure compatibility with the production continuity (batch / continuous). At the same time, refer to energy consumption, maintenance costs, and industry reputation to ensure it matches the process.