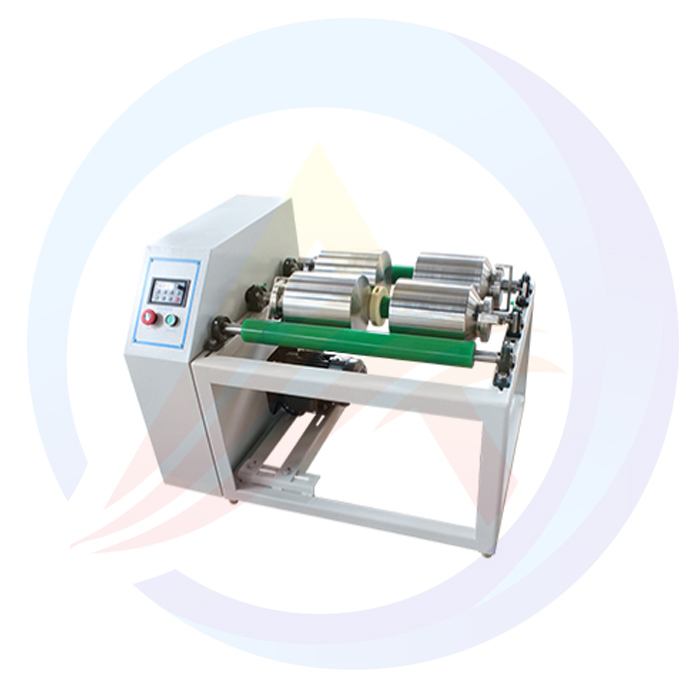

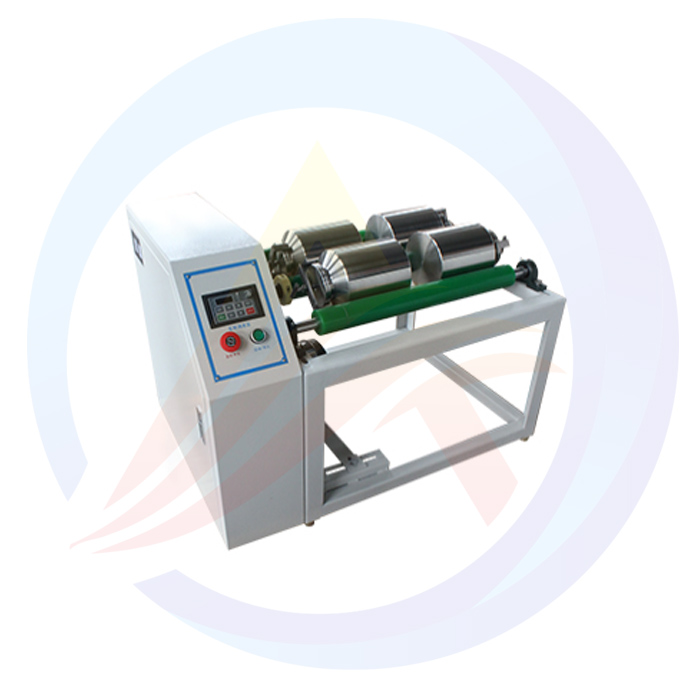

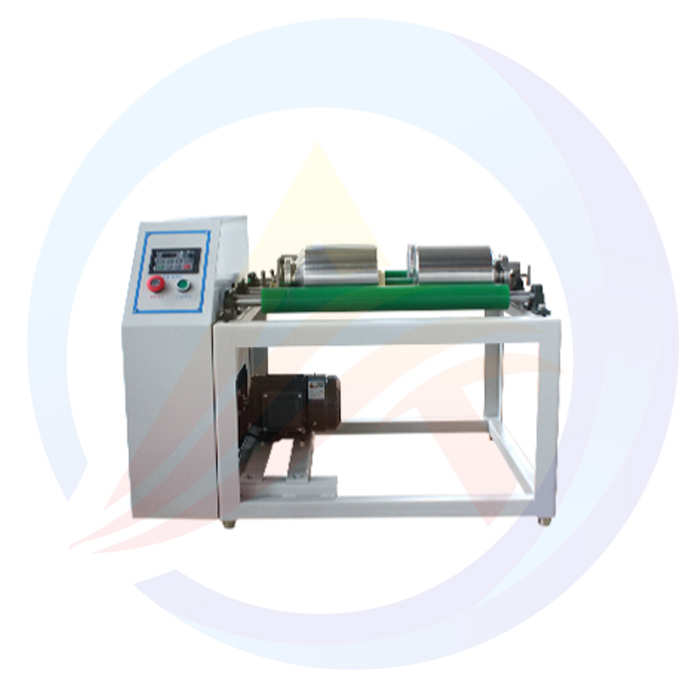

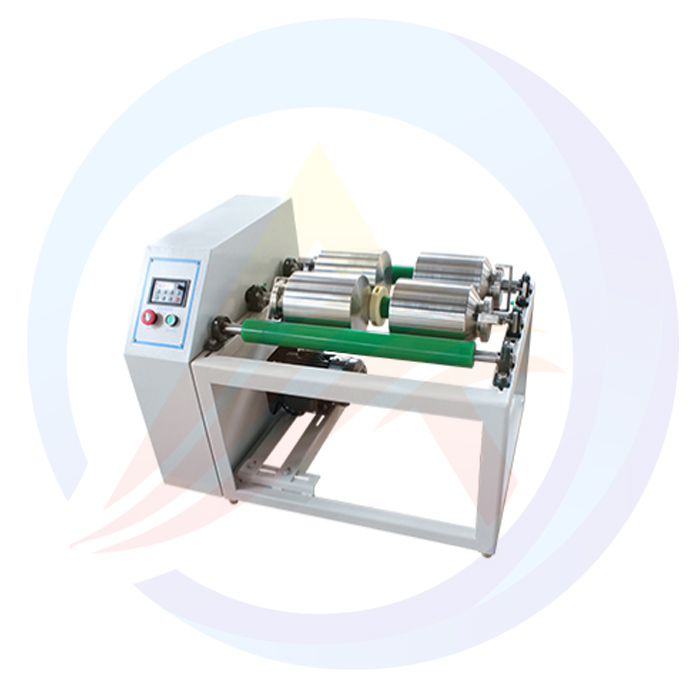

Introduction to the Four-Position Drum Grinder

The tank mill, also known as the bottle roller grinding machine, is a high-speed ultra-fine grinding and mixing equipment used in laboratories and small-scale production. This machine is aesthetically pleasing, has a compact structure, is easy to operate, has high efficiency, and produces uniform fine particles. It is the preferred equipment for research, teaching, experimentation, and production. It can be widely used in industries such as electronic materials, magnetic materials, biomedicine, ceramic glaze pastes, metal powders, non-metallic minerals, and new materials. The machine has a novel appearance, advanced structure, and is easy to use. The tank body speed of this machine is optimally designed. The tank body is supported by rubber rollers and rotates, allowing the media balls inside the grinding tank to form a flow-like movement to disperse the materials, achieving the desired grinding effect. It can quickly grind the materials to the micron level. The tank mill (roller jar machine) is controlled by a digital display time controller. It can be set the working time at any time as needed, and has the functions of pause, cumulative timing control. The operation is time-saving and labor-saving, and it is easy and convenient.

Four-position drum grinder application

When the jar mill is in operation, the grinding media and the materials inside the cylinder rotate together with the cylinder and rise to a certain height. Due to the force of gravity, they separate from the cylinder wall and fall along a parabolic path. Under the impact of the grinding media and the friction and shear effects produced by the rolling and sliding of the grinding media, the materials are crushed.

Key features of Tianchuang Powder Four-Position Tank Grinding Machine

1. It can grind 4 samples simultaneously;

2. It can operate intermittently or continuously;

3. It can be set to operate at a certain time interval as per requirements;

4. It is suitable for fine grinding of materials, with high crushing efficiency;

5. The bearing rollers of the tank body are made of special materials and are durable.

Model | AOT-GQM-4-5 | AOT-GQM-4-5 (Double-layer) | AOT-GQM-4-15 | AOT-GQM-4-20 |

Overall Dimensions/Weight | 950X660X690/70KG | 950X480X870/(92KG) | 1130X800X690/95KG | 1350X820X690/122KG |

Motor Model/Power | YE2-80M2-4B3 /0.75KW | YE2-80M2-4B3 /0.75KW | YE2-90L-4B3 /1.5KW | YE2-100L1-4B3 /2.2KW |

Normal Power Supply | 220V, 50/60HZ | 220V, 50/60HZ | 220V, 50/60HZ | 380V, 50/60HZ |

Main Roller Speed (rpm) | 50 - 410±10 | 50 - 410±10 | 40 - 365±10 | 40 - 340±10 |

Hand Crank Dev | Optional | Optional | Optional | Optional |

Protective Cover | Optional | Optional | Optional | Optional |

Company Profile

Xiamen AOT battery equipment Technology Co LTD was set up as a manufacturer in 2006. We have total manufacturing facilities of around 4, 000 square meters and more than 65 staff. Owning a group of experienced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy. AOT Battery has been focused on product development and operations of lithium battery and its surrounding, we supply full kinds of lithium-ion battery equipment, lab battery raw materials and lithium-ion battery research and development technology.

Exhibition

AOT Lithium Battery Equipment exhibition provides exhibitors and visitors with a comprehensive platform for display, exchange, cooperation and trade. By participating in the exhibition, enterprises can understand the industry dynamics, expand market channels, enhance brand image and promote technological innovation and industrial upgrading.

Certificate

Cooperative

FAQ

Q.What is Bottle Roller Grinding Machine

A.the Bottle Roller Grinding Machine polishes cylindrical battery casings (like those for lithium-ion cells). It uses rotating rollers with abrasives to smooth metal surfaces, remove burrs, and ensure dimensional precision. This enhances casing sealability, reduces short-circuit risks, and improves adhesion for subsequent processes (e.g., coating), critical for battery safety and performance.

Q.The function of the Bottle Roller Grinding Machine

A.The Bottle Roller Grinding Machine uses rotating rollers in combination with abrasive materials to process the surface of the metal shell, removing burrs, scratches and other defects, and improving the smoothness and dimensional accuracy. This not only enhances the sealing performance of the shell, reduces the risk of short circuits, but also optimizes the adhesion effect of subsequent coating and other processes, which is of vital importance for ensuring the safety and performance stability of the battery.